This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

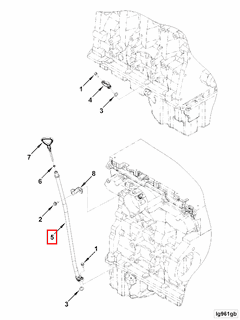

The Cummins 5294000 Oil Gauge Tube is a vital component designed to facilitate the monitoring of oil levels within the engine of commercial trucks. This part ensures the engine operates within optimal parameters, contributing to the overall efficiency and longevity of the vehicle 4.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a component that allows for the measurement and display of oil levels within an engine. It functions by connecting to the oil reservoir and transferring the oil level information to the gauge on the dashboard. This system is essential for monitoring the engine’s lubrication status, which is crucial for preventing engine wear and ensuring smooth operation 1.

Purpose and Role of the Cummins 5294000 Oil Gauge Tube

The Cummins 5294000 specifically serves to provide accurate oil level readings in commercial trucks. By ensuring that the oil level is maintained within the appropriate range, it aids in preserving engine performance and preventing potential damage due to insufficient lubrication. This component is integral to the engine’s lubrication system, facilitating the continuous and efficient operation of the truck 2.

Key Features

The Cummins 5294000 is characterized by its robust design and the use of high-quality materials, which enhance its durability and reliability. Its construction is tailored to withstand the demanding conditions typical of commercial truck operations, ensuring consistent performance over time. Additionally, the tube is designed for easy integration with the truck’s existing systems, minimizing installation complexity 3.

Benefits of Using the Cummins 5294000 Oil Gauge Tube

Utilizing the Cummins 5294000 offers several advantages. It provides improved accuracy in oil level readings, which is crucial for maintaining engine health. Its durable construction ensures longevity, reducing the need for frequent replacements. Furthermore, the reliability of this component contributes to the overall efficiency and safety of the truck’s operation 4.

Installation and Integration

Installing the Cummins 5294000 involves several steps to ensure proper integration with the truck’s engine system. It is important to follow manufacturer guidelines for installation to ensure compatibility and optimal performance. Considerations include ensuring the tube is securely connected to the oil reservoir and that all connections are tight to prevent leaks 1.

Troubleshooting Common Issues

Common issues with the Cummins 5294000 may include inaccurate oil level readings or leaks. To address these problems, it is advisable to check the connections for tightness and ensure there are no obstructions within the tube. If inaccuracies persist, calibrating the gauge or inspecting the tube for damage may be necessary 2.

Maintenance Tips

To ensure the longevity and consistent performance of the Cummins 5294000, regular maintenance is recommended. This includes periodic checks for leaks, ensuring connections remain tight, and cleaning the tube as necessary to remove any buildup that could affect its operation. Adhering to these maintenance practices helps in preserving the component’s functionality and accuracy 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the commercial truck industry, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company’s products are engineered to meet the demanding requirements of commercial applications, ensuring reliability and performance 4.

Conclusion

The Cummins 5294000 Oil Gauge Tube is a critical component in maintaining the efficiency and longevity of commercial truck engines. Its accurate oil level readings, durable construction, and ease of integration make it an invaluable part of the engine’s lubrication system. Regular maintenance and proper installation are key to ensuring its optimal performance and contributing to the overall reliability of the vehicle.

-

Meherwan P. Boyce, Gas Turbine Engineering Handbook, Second Edition, Gulf Professional Publishing, 2002.

↩ ↩ -

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ ↩ -

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ ↩ -

Clive Gifford, Cars Encyclopedia, DK Publishing, 2014.

↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.