This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

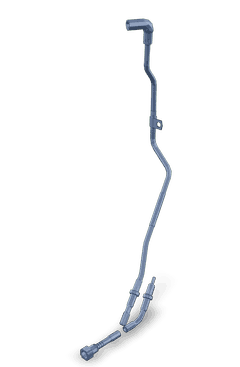

The Cummins Lubricating Oil Drain Tube, part number 5308977, is designed to facilitate the efficient drainage of lubricating oil from heavy-duty truck engines. Cummins, a prominent figure in the automotive industry, manufactures this part with an emphasis on durability and performance. Effective oil drainage systems are crucial for the maintenance of heavy-duty trucks, ensuring engines operate smoothly and efficiently by removing contaminants and degraded oil that accumulate over time 1.

Function and Operation

The Lubricating Oil Drain Tube operates as a conduit within the engine system, allowing used oil to be expelled from the engine block. This process is vital for maintaining engine health, as it ensures that the engine is not operating with oil that has become contaminated or has lost its lubricating properties. The tube is designed to handle the flow of oil during the drainage process, which is typically performed during routine maintenance checks 2.

Key Features

This Cummins part is constructed from materials that offer resistance to corrosion and high temperatures, ensuring longevity and reliable performance. Its design includes features that enhance its functionality, such as a secure fitting mechanism that prevents leaks and ensures a tight seal within the engine system. Additionally, the tube may incorporate unique attributes that facilitate easier installation and maintenance, contributing to its overall effectiveness 3.

Benefits of Using Lubricating Oil Drain Tube 5308977

Incorporating the Lubricating Oil Drain Tube into truck maintenance routines can lead to several advantages. These include improved engine longevity due to more efficient oil drainage, which helps in removing contaminants and degraded oil. The design of the tube also contributes to ease of maintenance, allowing for quicker and more straightforward oil change procedures.

Installation and Compatibility

Proper installation of the Lubricating Oil Drain Tube is crucial for its effective operation. Guidelines for installation should be followed to ensure that the tube is securely fitted and functions as intended. Compatibility with various truck models and engine types is an important consideration, ensuring that the tube can be used across a range of applications without the need for modifications.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure that the Lubricating Oil Drain Tube continues to function correctly. This may include checking for signs of wear or damage and ensuring that all connections are secure. Common issues that may arise include leaks or blockages, which can often be addressed through routine checks and timely replacements or repairs.

Safety Considerations

When working with the Lubricating Oil Drain Tube, it is important to observe safety practices to prevent accidents or injuries. This includes taking precautions during installation, maintenance, and troubleshooting to ensure that the work environment is safe and that all procedures are performed correctly.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines and related technologies, as well as filtration and emissions solutions, demonstrating its comprehensive approach to powering the world.

Cummins Lubricating Oil Drain Tube (Part 5308977) Compatibility

The Cummins part number 5308977, which is a Lubricating Oil Drain Tube, is designed to fit seamlessly within a variety of Cummins engine models. This part is integral to the engine’s oil management system, ensuring that oil is drained efficiently and effectively, thereby maintaining optimal engine performance and longevity.

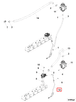

ISL G CM2180 Engines

The ISL G CM2180 engines are part of Cummins’ robust lineup of industrial and power generation engines. The 5308977 oil drain tube is specifically engineered to fit these engines, ensuring that oil is drained from the engine’s sump without leaks or blockages. This compatibility is crucial for maintaining the engine’s operational efficiency and preventing potential damage from oil contamination or overheating.

Group Compatibility

The 5308977 oil drain tube is also compatible with other engines within the same family or group as the ISL G CM2180. This includes various configurations and versions of Cummins engines that share similar design and engineering principles. Ensuring that the oil drain tube fits these engines is essential for maintaining the integrity of the engine’s oil system and preventing performance issues.

By ensuring that the 5308977 oil drain tube is correctly installed in the ISL G CM2180 engines and other compatible models, engine operators can rely on consistent and reliable oil drainage, contributing to the overall health and efficiency of their engines.

Role of Part 5308977 Lubricating Oil Drain Tube in Engine Systems

The 5308977 Lubricating Oil Drain Tube is a critical component in the maintenance and operation of various engine systems. Its primary function is to facilitate the efficient drainage of lubricating oil from the crankcase, ensuring that the engine operates smoothly and effectively.

Integration with Crankcase and Breather Systems

In the context of the crankcase, the 5308977 tube plays a significant role in maintaining the proper oil level. By allowing excess oil to be drained, it prevents oil dilution and contamination, which can adversely affect engine performance. The tube is typically connected to the lower part of the crankcase, where it interfaces with the oil sump. This arrangement ensures that oil can be efficiently removed during maintenance procedures, such as oil changes.

The breather system also benefits from the presence of the 5308977 tube. The crankcase breather is designed to release pressure build-up within the crankcase, which occurs due to the combustion process. The breather system often includes a PCV (Positive Crankcase Ventilation) valve that routes these gases back into the intake manifold for re-burning. The 5308977 tube ensures that any oil that might be carried over with these gases is effectively separated and drained, preventing it from entering the intake system and causing fouling or performance issues.

Enhancing Engine Arrangement and Maintenance

The arrangement of the 5308977 tube within the engine compartment is carefully considered to optimize both functionality and accessibility. It is usually positioned in a manner that allows for easy connection to oil drainage equipment, such as funnels or collection pans. This thoughtful placement aids mechanics during routine maintenance, reducing the time and effort required for oil changes and inspections.

Furthermore, the tube’s design often includes features that prevent oil leaks and ensure a secure fit within the crankcase. This reliability is essential for maintaining the engine’s integrity over time, as consistent and proper oil drainage contributes to the longevity and efficiency of the engine components.

Conclusion

In summary, the 5308977 Lubricating Oil Drain Tube is a vital component that enhances the functionality and maintenance of engine systems by ensuring efficient oil drainage, supporting the breather system, and contributing to the overall arrangement and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.