This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

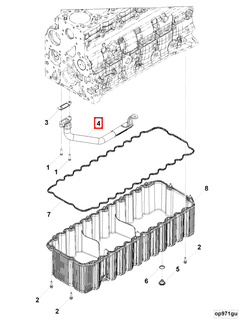

The Lubricating Oil Suction Tube 5310214 is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its high-quality heavy-duty truck parts. This suction tube is integral to the lubrication system of heavy-duty trucks, ensuring that the engine receives a consistent supply of oil for optimal performance and longevity.

Function and Operation

The Lubricating Oil Suction Tube 5310214 operates within the engine’s lubrication system by facilitating the circulation of oil from the oil pan to the engine’s various moving parts. It plays a role in maintaining a steady oil flow, which is vital for reducing friction, cooling components, and removing contaminants 1. The efficient operation of this tube ensures that the engine components are adequately lubricated, which contributes to maintaining optimal engine performance and durability.

Key Features

The design and construction of the Lubricating Oil Suction Tube 5310214 are tailored to meet the demanding requirements of heavy-duty engines. It is made from high-quality materials that offer durability and resistance to the harsh conditions within an engine. The tube’s construction includes precise engineering to ensure a secure fit and reliable performance. Additionally, it may feature unique attributes such as anti-corrosion coatings or reinforced sections to enhance its longevity and effectiveness in the engine environment 2.

Benefits

The advantages provided by the Lubricating Oil Suction Tube 5310214 include improved engine lubrication, which leads to reduced wear and tear on engine components. This consistent lubrication helps in maintaining engine efficiency and extends the overall lifespan of the engine. Furthermore, the tube’s reliable performance contributes to the stability and reliability of the engine’s lubrication system 3.

Installation and Compatibility

For the proper installation of the Lubricating Oil Suction Tube 5310214, it is important to follow manufacturer guidelines to ensure compatibility with the specific engine model. Proper installation involves securing the tube in place and ensuring there are no obstructions to the oil flow. Specific requirements for installation may vary depending on the engine model, and it is advisable to consult the manufacturer’s instructions for detailed guidance.

Maintenance and Troubleshooting

Routine maintenance practices for the Lubricating Oil Suction Tube 5310214 include regular inspections for signs of wear, leaks, or damage. It is also important to ensure that the tube is free from obstructions and that the oil flow is not restricted. Troubleshooting common issues may involve checking for proper installation, ensuring the tube is securely fastened, and addressing any leaks or damage promptly to maintain the efficiency of the lubrication system.

Safety Considerations

When working with the Lubricating Oil Suction Tube 5310214, it is important to observe safety precautions and best practices. This includes proper handling to avoid damage to the tube, secure storage to prevent contamination, and following appropriate disposal procedures for any waste materials. Additionally, it is crucial to ensure that all work is performed in a safe environment, with adequate ventilation and protection against spills or leaks.

Regulatory Compliance

The Lubricating Oil Suction Tube 5310214 adheres to relevant regulatory standards and certifications, ensuring compliance with industry regulations and safety guidelines. This commitment to compliance reflects Cummins’ dedication to manufacturing components that meet or exceed industry standards for quality and safety.

Cummins Overview

Cummins is a reputable manufacturer in the automotive industry, with a history of producing high-quality components for heavy-duty trucks. The company is known for its commitment to innovation, quality, and customer satisfaction. Cummins’ reputation is built on a foundation of manufacturing excellence and a dedication to providing reliable and durable parts for the demanding environments of heavy-duty applications.

Cummins Engine Compatibility with Lubricating Oil Suction Tube Part 5310214

The Cummins part 5310214, a Lubricating Oil Suction Tube, is designed to fit seamlessly within a range of Cummins engines, ensuring optimal oil flow and engine performance. This part is integral to the engine’s lubrication system, facilitating the suction of oil from the sump to the oil pump.

B6.7 CM2350 and B135B Engines

The B6.7 CM2350 and B135B engines are part of Cummins’ lineup that benefits from the precise engineering of the 5310214 oil suction tube. This part ensures that the oil is drawn efficiently from the oil pan, maintaining the necessary lubrication throughout the engine’s components. The design of the tube is tailored to fit the specific architecture of these engines, ensuring a snug fit and reliable performance.

ISB6.7 G CM2180 and B118 Engines

Similarly, the ISB6.7 G CM2180 and B118 engines are equipped with the 5310214 oil suction tube, which is engineered to meet the unique requirements of these models. The tube’s design allows for consistent oil flow, which is crucial for the longevity and efficiency of the engine. The compatibility of this part with these engines underscores Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and durability.

Conclusion

The 5310214 oil suction tube is a critical component in the Cummins engine ecosystem, ensuring that the lubrication system functions as intended. Its design and fit are meticulously crafted to ensure that it works flawlessly with the specified engines, contributing to the overall reliability and performance of the engine.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.