This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

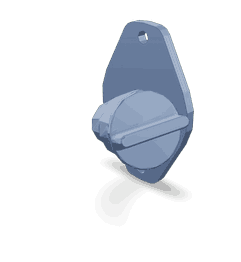

The Cummins Oil Filler Tube Assembly, part number 5311763, is a component designed for use in commercial trucks. This assembly facilitates the addition of oil to the engine, playing a role in the operation of these vehicles. Cummins, a well-regarded name in the automotive industry, manufactures this part with a focus on reliability and performance.

Purpose and Function

The Oil Filler Tube Assembly serves a role in the lubrication system of a truck engine. Its primary function is to provide a conduit through which oil can be added to the engine. This assembly ensures that oil is directed into the engine’s crankcase, where it lubricates moving parts, reduces friction, and helps in cooling the engine. The design of the assembly allows for efficient oil addition while minimizing the risk of spills and ensuring that the oil reaches its intended destination within the engine 1.

Key Features

The Oil Filler Tube Assembly 5311763 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity even in demanding commercial truck environments. The design of the assembly includes a secure fitting mechanism that ensures a tight seal, preventing oil leaks. Additionally, the assembly may feature a built-in dipstick tube for easy oil level checks, streamlining the maintenance process 2.

Benefits

The use of the Oil Filler Tube Assembly 5311763 offers several benefits. It contributes to improved oil flow into the engine, ensuring that the lubrication system operates efficiently. The design reduces the risk of oil spills during the addition process, making maintenance safer and cleaner. Furthermore, the secure fitting mechanism enhances safety during oil changes by preventing leaks and ensuring that oil is correctly directed into the engine 3.

Installation Process

Installing the Oil Filler Tube Assembly 5311763 requires attention to detail to ensure proper function and safety. The process involves removing the old assembly, if present, and cleaning the installation area to ensure a clean surface for the new part. The new assembly should be aligned with the engine’s oil fill port and secured according to the manufacturer’s instructions. Tools required may include wrenches for securing the assembly and a funnel for adding oil. It is important to follow the manufacturer’s guidelines to ensure a successful installation.

Maintenance Tips

To ensure the optimal performance and longevity of the Oil Filler Tube Assembly, routine maintenance is recommended. This includes regular cleaning of the assembly to remove any dirt or debris that may accumulate. Inspections for signs of wear or damage should be conducted, and any issues should be addressed promptly to prevent further complications. Following the manufacturer’s guidelines for replacement intervals can help maintain the efficiency of the lubrication system.

Troubleshooting Common Issues

Common issues with the Oil Filler Tube Assembly may include oil leaks, difficulty in adding oil, or damage to the assembly. Troubleshooting steps may involve checking the secure fitting mechanism for proper alignment and tightness, inspecting the assembly for signs of wear or damage, and ensuring that the oil being added is compatible with the engine’s requirements. Addressing these issues promptly can help maintain the efficiency of the lubrication system and prevent more serious engine problems.

Safety Considerations

When working with the Oil Filler Tube Assembly, it is important to observe safety precautions. This includes handling oil with care to avoid spills and ensuring that the assembly is securely fitted to prevent leaks. Adhering to the manufacturer’s guidelines for installation and maintenance is crucial to ensure safety and the proper function of the assembly. Additionally, wearing appropriate personal protective equipment (PPE) when performing maintenance or repairs can help protect against potential hazards.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its high-quality components and engines. With a history of innovation and commitment to excellence, Cummins has established a reputation for producing reliable and durable parts that meet the demanding requirements of commercial vehicles. The company’s focus on quality and performance is evident in its wide range of products, including the Oil Filler Tube Assembly 5311763.

Cummins Oil Filler Tube Assembly 5311763 Compatibility with Engine Models

The Cummins Oil Filler Tube Assembly part number 5311763 is designed to fit seamlessly with several engine models, ensuring optimal performance and ease of maintenance. This part is integral to the engine’s oil management system, facilitating the addition of oil and monitoring oil levels.

Compatible Engines

-

F3.8 CM2350 F107 and QSF3.8 CM2350 F107

The Oil Filler Tube Assembly 5311763 is specifically engineered to fit the F3.8 CM2350 F107 and QSF3.8 CM2350 F107 engines. This compatibility ensures that the assembly integrates smoothly with the engine’s design, providing a reliable method for oil replenishment and level checking.

-

F4.5 CM2620 F141C

The part number 5311763 is also compatible with the F4.5 CM2620 F141C engine. This compatibility is crucial for maintaining the engine’s operational integrity, as the oil filler tube assembly plays a key role in the engine’s lubrication system.

-

QSF3.8 CM2880 F112

Lastly, the Oil Filler Tube Assembly 5311763 fits the QSF3.8 CM2880 F112 engine. This compatibility ensures that the assembly can be used across different engine configurations, providing a standardized solution for oil management.

By ensuring compatibility with these engine models, the Cummins Oil Filler Tube Assembly 5311763 offers a reliable and efficient way to manage the engine’s oil levels, contributing to the overall performance and longevity of the engine.

Role of Part 5311763 Oil Filler Tube Assembly in Engine Systems

The part 5311763 Oil Filler Tube Assembly is integral to the arrangement of components within engine systems, specifically in the oil fill process. This assembly serves as the conduit for replenishing the engine’s lubrication system with oil. It is strategically positioned to interface with the oil tank or reservoir, ensuring a seamless flow of oil into the engine.

In the context of the oil fill arrangement, the Oil Filler Tube Assembly works in conjunction with the oil cap, which is often equipped with a dipstick for measuring oil levels. The assembly is designed to align perfectly with the cap, allowing for easy removal and reinstallation during maintenance procedures.

Furthermore, the assembly is engineered to prevent spills and ensure that oil is directed accurately into the engine’s crankcase. This precision is vital for maintaining the integrity of the oil fill process, which is essential for the engine’s performance and longevity. The assembly also incorporates features that may include baffles or guides to enhance the flow of oil and reduce the likelihood of air ingestion, which can lead to foamy oil and inaccurate level readings.

Conclusion

In summary, the Cummins Oil Filler Tube Assembly, part number 5311763, is a key component in the oil fill arrangement, facilitating the efficient and clean replenishment of engine oil, and contributing to the overall reliability and efficiency of the engine system. Its design, compatibility with various engine models, and the benefits it offers make it a valuable part for maintaining the performance and longevity of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.