This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

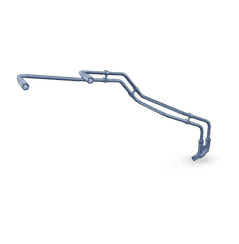

The Lubricating Oil Drain Tube 5317028 by Cummins is designed to facilitate the efficient drainage of used oil from heavy-duty truck engines. This part is integral to the maintenance routine of such vehicles, ensuring that the engine operates smoothly and efficiently by allowing for regular oil changes. Proper oil drainage is vital for maintaining engine health, as it removes contaminants and degraded oil that can otherwise lead to engine wear and reduced performance 1.

Function and Operation

The Lubricating Oil Drain Tube operates by providing a conduit for used oil to exit the engine during an oil change. It is positioned to align with the oil pan’s drain plug, allowing for a streamlined process of oil removal. Regular oil changes are important for engine health, as they help to remove contaminants and ensure that the engine is lubricated with fresh oil, which is crucial for reducing friction and wear on engine components 2.

Key Features

This Cummins part is constructed from durable materials that are resistant to the high temperatures and chemical properties of engine oil. Its design includes features that enhance its performance, such as a secure fitting mechanism that ensures a tight seal during operation, preventing leaks. The tube’s material and design contribute to its longevity and reliability in demanding heavy-duty applications 3.

Benefits of Using Lubricating Oil Drain Tube 5317028

Incorporating this part into truck maintenance routines offers several advantages. It contributes to improved engine longevity by ensuring that oil changes are conducted efficiently, which helps to maintain optimal engine lubrication. The tube’s design facilitates quick and clean oil drainage, reducing downtime during maintenance. Additionally, its durability and ease of use make it a convenient component for regular maintenance tasks.

Installation Process

Installing the Lubricating Oil Drain Tube 5317028 involves several steps to ensure proper fitting and function. The process requires basic hand tools and should be conducted with the engine cool to avoid burns. Safety precautions, such as wearing protective gloves and eyewear, should be observed. The tube is aligned with the drain plug, and the fitting mechanism is engaged to secure it in place. Detailed instructions should be followed to ensure a correct installation.

Maintenance and Care

Regular inspection and maintenance of the Lubricating Oil Drain Tube are recommended to ensure optimal performance. This includes checking for signs of wear or damage that could affect its sealing capability. Cleaning the tube after each use can help to prevent the buildup of debris, which could interfere with its operation. If signs of wear are detected, replacement of the tube should be considered to maintain efficient oil drainage.

Troubleshooting Common Issues

Common issues associated with Lubricating Oil Drain Tubes include leaks and blockages. Leaks may occur due to improper installation or wear on the tube, while blockages can result from debris accumulation. Addressing these issues involves inspecting the tube for damage, ensuring it is correctly installed, and cleaning it thoroughly to remove any obstructions. In cases where the tube is damaged, replacement may be necessary to restore proper function.

Environmental Considerations

Proper oil drainage plays a role in responsible waste oil management. The Lubricating Oil Drain Tube facilitates the efficient collection of used oil, which can then be disposed of or recycled according to environmental regulations. This contributes to reducing the environmental impact of oil disposal and supports sustainable practices in vehicle maintenance.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, from on-highway to off-highway and stationary power.

Cummins Lubricating Oil Drain Tube Part 5317028 Compatibility

The Cummins part 5317028, a Lubricating Oil Drain Tube, is designed to fit seamlessly within a range of Cummins engine models. This part is integral to the maintenance and operational efficiency of these engines, ensuring that oil is properly drained and the engine remains lubricated.

B6.7 CM2350

The B6.7 CM2350 engine is one of the models that benefit from the 5317028 drain tube. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The drain tube in this engine ensures that oil is efficiently removed from the sump, preventing sludge buildup and maintaining optimal engine health.

B135B

The B135B engine also utilizes the 5317028 drain tube. This engine is part of Cummins’ lineup of smaller, yet powerful engines, typically used in a variety of industrial and agricultural applications. The drain tube in the B135B engine is crucial for maintaining the engine’s lubrication system, ensuring smooth operation and longevity.

Grouping of Engines

The 5317028 drain tube is compatible with both the B6.7 CM2350 and B135B engines, highlighting its versatility and importance across different engine sizes and applications. This compatibility ensures that maintenance personnel can use a single part for multiple engine models, simplifying inventory management and reducing downtime.

Role of Part 5317028 Lubricating Oil Drain Tube in Engine Systems

In the context of engine systems, the 5317028 Lubricating Oil Drain Tube is an essential component that facilitates the efficient management of lubricating oil. This tube is integral to the breather and crankcase systems, ensuring optimal engine performance and longevity.

Integration with the Breather System

The breather system is designed to regulate pressure within the crankcase by allowing air to enter and exit as needed. The 5317028 tube plays a significant role here by providing a dedicated pathway for oil that may be carried over from the crankcase ventilation process. This ensures that any oil mist or foam is effectively separated from the air, preventing contamination and maintaining the breather system’s efficiency.

Function within the Crankcase System

In the crankcase system, the 5317028 Lubricating Oil Drain Tube is responsible for draining excess oil that accumulates during engine operation. This is particularly important in preventing oil dilution and ensuring that the oil remains at the optimal level for lubrication. By efficiently draining this excess oil, the tube helps maintain the crankcase’s integrity and supports the overall lubrication process, which is vital for reducing friction and wear on engine components.

Overall Impact on Engine Performance

The effective operation of the 5317028 tube within these systems contributes to stable engine performance. It ensures that the breather system functions without oil contamination, and the crankcase maintains the correct oil levels. This, in turn, supports consistent lubrication, reduces the risk of engine wear, and enhances the engine’s reliability and efficiency.

Conclusion

The Lubricating Oil Drain Tube 5317028 by Cummins is a critical component in the maintenance and operation of heavy-duty truck engines. Its role in facilitating efficient oil drainage contributes to engine longevity, performance, and environmental sustainability. Proper installation, maintenance, and troubleshooting of this part are essential for ensuring optimal engine health and operational efficiency.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.