This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

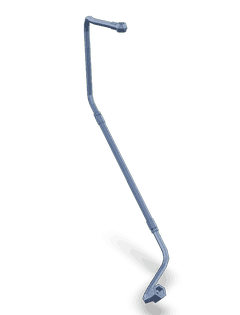

The Turbo Oil Supply Tube, identified by part number 5319488, is a component manufactured by Cummins, a leading name in the commercial truck industry. This tube is integral to the operation of heavy-duty truck engines, particularly in ensuring the efficient functioning of the turbocharger. Cummins, known for its robust and reliable engine components, designs this tube to meet the demanding requirements of modern trucking applications 5.

Function and Operation

This Cummins part operates by facilitating the flow of lubricant oil from the engine’s oil system to the turbocharger. This tube is a critical conduit that ensures the turbocharger receives a consistent supply of oil, which is necessary for its operation. The oil lubricates the turbocharger’s bearings and helps in cooling the turbine, thereby enhancing the overall efficiency and longevity of the turbocharger 1.

Purpose of the Turbo Oil Supply Tube

The primary role of the Turbo Oil Supply Tube is to contribute to the turbocharger’s lubrication system. By supplying oil to the turbocharger, it ensures that the turbocharger’s moving parts are adequately lubricated, reducing friction and wear. This lubrication is vital for maintaining engine performance and reliability, as it allows the turbocharger to operate efficiently under various load conditions 2.

Key Features

The Turbo Oil Supply Tube is constructed from high-quality materials that are resistant to the high temperatures and pressures found in heavy-duty truck engines. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to withstand the dynamic forces exerted during engine operation 3.

Benefits

The advantages of using the Turbo Oil Supply Tube include improved turbocharger efficiency due to consistent oil supply, enhanced engine reliability through reduced wear on turbocharger components, and potential increases in fuel economy as a result of optimized turbocharger performance. These benefits contribute to the overall effectiveness and durability of the engine 4.

Installation and Compatibility

Proper installation of the Turbo Oil Supply Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure compatibility with the specific engine model. Attention to detail during installation helps prevent leaks and ensures that the tube functions as intended within the engine system 5.

Maintenance and Troubleshooting

Routine maintenance of the Turbo Oil Supply Tube involves checking for signs of wear, leaks, or blockages. Regular inspection and cleaning can help maintain its efficiency. Troubleshooting common issues such as leaks may involve tightening connections or replacing damaged sections of the tube to restore proper function 5.

Common Failure Modes

Typical failure modes of the Turbo Oil Supply Tube include leaks due to worn fittings, blockages from contaminants in the oil, and structural damage from excessive heat or pressure. Addressing these issues promptly can prevent more severe engine problems and maintain the turbocharger’s performance 5.

Upgrades and Modifications

There may be available upgrades or modifications for the Turbo Oil Supply Tube that aim to enhance performance or address specific operational needs. These could include reinforced designs for higher durability or specialized coatings to improve resistance to heat and corrosion 5.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins is renowned for its innovative engine technologies and commitment to quality. The company’s product range includes engines, filtration systems, and related components, all designed to meet the rigorous demands of the commercial truck industry. Cummins’ reputation for reliability and performance makes it a preferred choice among fleet operators and maintenance professionals 5.

Role of Part 5319488 Turbo Oil Supply Tube in Engine Systems

This part is an essential component in the efficient operation of turbocharged engine systems. This tube is integral to the turbocharger plumbing system, ensuring a consistent and reliable flow of oil to the turbocharger.

In the context of turbocharger systems, the Turbo Oil Supply Tube connects the engine’s lubrication system to the turbocharger. Its primary function is to deliver pressurized oil from the engine to the turbocharger’s bearing and turbine components. This oil supply is vital for lubricating moving parts, reducing friction, and dissipating heat generated during operation.

Within the turbocharger plumbing network, the Turbo Oil Supply Tube works in conjunction with other components such as oil filters, relief valves, and return lines. It ensures that the turbocharger receives the necessary oil pressure to maintain optimal performance and longevity. The tube’s design and placement are engineered to withstand high pressures and temperatures, contributing to the overall reliability of the turbocharger system.

Conclusion

In summary, the Turbo Oil Supply Tube plays a significant role in the turbocharger plumbing system by providing essential lubrication to the turbocharger, thereby enhancing the efficiency and durability of the engine system. Proper installation, maintenance, and understanding of its function are crucial for maximizing the benefits of this Cummins part.

-

Kluczyk, Barry, How to Rebuild Any Automotive Engine, CarTech, 2008.

↩ -

Bartz, Wilfried J, Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, CRC Press, 2019.

↩ -

Sheng, Gang, Vehicle Noise, Vibration and Sound Quality, SAE International, 2012.

↩ -

Aird, Forbes, Bosch Fuel Injection Systems, HP Books, 2001.

↩ -

Cummins Inc., “Operation and Maintenance Manual,” Bulletin Number 4332779, QSB6.7 CM2350 B105.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.