This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

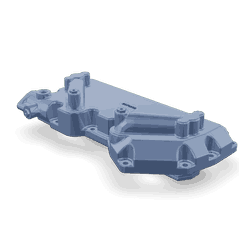

The Cummins 5320555 Oil Cooler Housing is a component designed to facilitate the cooling of engine oil in commercial trucks. Its role is significant in maintaining the operational efficiency and longevity of the engine by ensuring that the oil remains within optimal temperature ranges 1.

Basic Concepts of Oil Cooler Housing

An Oil Cooler Housing is a part of the engine cooling system that encases the oil cooler. Its function is to protect the oil cooler and facilitate the dissipation of heat from the engine oil. By maintaining the oil at an optimal temperature, the housing contributes to the overall efficiency and reliability of the engine 2.

Purpose of the 5320555 Oil Cooler Housing

The 5320555 Oil Cooler Housing aids in the dissipation of heat from the engine oil. This is achieved through the circulation of oil through the cooler, where it is exposed to ambient air or a coolant, thereby reducing its temperature before it is recirculated through the engine.

Key Features

This Cummins part is characterized by its robust design and the materials used in its construction, which are chosen for their durability and heat resistance. Unique attributes such as precise engineering and compatibility with specific engine models enhance its performance and reliability.

Benefits of Using the 5320555 Oil Cooler Housing

The advantages provided by this part include improved engine longevity due to consistent oil temperature management, enhanced performance as a result of optimal lubrication conditions, and reliability across various operating conditions, ensuring that the engine operates efficiently under different loads and temperatures.

Installation Process

Proper installation of the 5320555 Oil Cooler Housing involves several steps, including preparation of the installation site, alignment with the engine’s oil system, secure mounting, and connection to the oil lines. Tools required may include wrenches, gaskets, and sealants to ensure a leak-free connection.

Maintenance and Troubleshooting

Regular maintenance practices for the 5320555 Oil Cooler Housing include inspection for leaks, cleaning of the exterior to remove dirt and debris, and checking the condition of the gaskets and seals. Common issues that may arise include leaks or reduced cooling efficiency, which can often be addressed through inspection, cleaning, or replacement of worn components.

Performance in Various Conditions

The 5320555 Oil Cooler Housing is designed to perform effectively under a range of operating conditions, including extreme temperatures and heavy-duty usage. Its construction and design allow it to maintain optimal oil temperature, contributing to engine efficiency and longevity in demanding environments.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction.

Understanding the Integration of Part 5320555 Oil Cooler Housing in Engine Systems

In the context of engine systems, the oil cooler housing, specifically part 5320555, serves as a vital interface between the cooler and the engine oil. This housing is designed to encase and protect the oil cooler, ensuring efficient heat exchange and maintaining optimal oil temperature for engine performance.

Role in the Engine Oil System

The oil cooler housing facilitates the circulation of engine oil through the cooler. As the oil passes through the cooler, it dissipates heat, which is then transferred to the surrounding environment, typically via air or a secondary coolant system. This process is essential for maintaining the oil at an optimal temperature, which in turn ensures that the oil retains its viscosity and lubricating properties.

Interaction with Other Components

-

Oil Pump: The housing connects to the oil pump, which supplies pressurized oil to the cooler. This pressurized flow ensures that the oil moves efficiently through the cooler, enhancing the heat exchange process.

-

Oil Filter: Post-cooling, the oil often passes through the oil filter, which removes any contaminants that may have been dislodged during the cooling process. The housing ensures a smooth transition of oil from the cooler to the filter.

-

Engine Block: The cooled oil is then circulated back into the engine block, where it lubricates moving parts, reduces friction, and carries away heat from critical components.

-

Thermostat: In some systems, a thermostat may be integrated to regulate the flow of oil based on temperature, ensuring that the oil is only cooled when necessary. The housing provides a pathway for the thermostat to interact with the oil flow.

Enhanced System Performance

By effectively housing the oil cooler, part 5320555 plays a significant role in enhancing the overall performance and longevity of the engine. It ensures that the oil remains at an optimal temperature, which is essential for the efficient operation of the engine and the protection of its internal components.

Conclusion

The Cummins 5320555 Oil Cooler Housing is a critical component in the cooling system of various engines, designed to regulate the temperature of the engine oil, ensuring optimal performance and longevity of the engine. Its robust design, precise engineering, and compatibility with specific engine models enhance its performance and reliability. Regular maintenance and proper installation are key to ensuring the effective operation of this part, contributing to the overall efficiency and reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.