This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

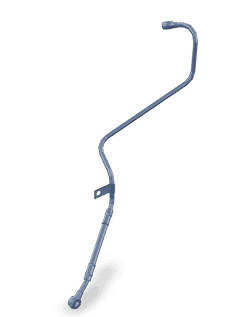

The Cummins 5332487 Oil Transfer Connection is a component designed to facilitate the transfer of oil within the lubrication system of commercial trucks. Its role is significant in ensuring that various engine components receive adequate lubrication, which is vital for the smooth operation and longevity of the engine 1.

Basic Concepts of Oil Transfer Connection

An Oil Transfer Connection is a part that enables the movement of oil from one part of the lubrication system to another. Within a truck’s lubrication system, it ensures that oil is distributed efficiently to critical engine components. This distribution is important for maintaining engine health, as proper lubrication reduces friction, wear, and heat generation within the engine 2.

Purpose of the 5332487 Oil Transfer Connection

The 5332487 Oil Transfer Connection is designed to transfer oil between different components and systems within a truck’s engine. By facilitating this transfer, it ensures that all parts of the engine receive the necessary lubrication to operate efficiently. This component plays a role in maintaining the integrity of the lubrication system by ensuring consistent oil flow to areas that require it 3.

Key Features

The 5332487 Oil Transfer Connection is characterized by its robust design and the materials used in its construction. It is built to withstand the pressures and temperatures within a truck’s engine compartment. The connection is designed for durability, with features that enhance its performance and longevity. These may include precision-machined surfaces for a secure fit and materials that resist corrosion and wear 4.

Benefits

The use of the 5332487 Oil Transfer Connection offers several benefits. It contributes to improved lubrication efficiency by ensuring that oil is distributed effectively throughout the engine. This enhanced lubrication protects engine components from wear and reduces the risk of overheating. Additionally, by maintaining optimal lubrication, the connection can contribute to overall truck performance and longevity 5.

Installation Process

Installing the 5332487 Oil Transfer Connection requires careful attention to detail to ensure a secure and effective fit. The process involves preparing the connection area, aligning the connection with its mating part, and securing it in place. Tools required may include wrenches and sealants, and it is important to follow manufacturer guidelines to avoid damage to the connection or the lubrication system 6.

Troubleshooting Common Issues

Common issues with the 5332487 Oil Transfer Connection may include leaks or malfunctions. Troubleshooting these problems involves inspecting the connection for signs of wear or damage, checking for proper alignment and fit, and ensuring that all seals are intact. Solutions may range from tightening connections to replacing damaged parts 7.

Maintenance Tips

Regular maintenance of the 5332487 Oil Transfer Connection is important for its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the connection area to prevent contamination, and ensuring that all seals and fittings are in good condition. Following these practices can help prevent issues and ensure the connection continues to function effectively 8.

Integration with Plumbing Systems

The 5332487 Oil Transfer Connection is instrumental in the efficient operation of engine plumbing systems. It facilitates the seamless transfer of oil between various components, ensuring that all parts receive the necessary lubrication. This connection is typically integrated into the oil return lines, allowing oil to flow from the turbocharger back to the sump or oil reservoir. Proper integration ensures that oil pressure is maintained, reducing the risk of component wear and enhancing the longevity of the engine’s plumbing network 9.

Functionality with Turbochargers

In turbocharged engine systems, the 5332487 Oil Transfer Connection plays a significant role in maintaining the turbocharger’s performance. It is responsible for transferring oil to the turbocharger’s bearings and seals, which are essential for its operation. The connection ensures a consistent oil supply, which is vital for the turbocharger to function efficiently under high-stress conditions. This reliable oil transfer helps in cooling the turbocharger, reducing friction, and preventing overheating, thereby contributing to the overall efficiency and durability of the turbocharger 10.

Conclusion

The Cummins 5332487 Oil Transfer Connection is a critical component in the lubrication system of commercial trucks, ensuring efficient oil distribution and maintaining engine health. Its robust design, coupled with proper installation and maintenance, contributes to the longevity and performance of the engine. Understanding its role and importance can help in troubleshooting common issues and ensuring optimal engine operation.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5411260.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5411260.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5411260.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5411260.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5411260.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5411260.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.