This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

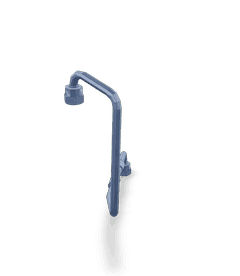

The Turbo Oil Supply Tube, identified by part number 5367475, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This tube is integral to the operation of heavy-duty truck engines, particularly those equipped with turbochargers. Its role is to facilitate the delivery of oil to the turbocharger, ensuring optimal performance and longevity of the turbo system 1.

Basic Concepts and Functionality

The Turbo Oil Supply Tube operates on the fundamental principle of delivering pressurized oil from the engine’s lubrication system to the turbocharger. This oil serves multiple functions, including lubrication of the turbo’s moving parts, cooling, and sealing. By maintaining a consistent flow of oil, the tube helps in reducing friction and wear on the turbocharger components, thereby contributing to the overall efficiency and reliability of the engine system 2.

Purpose and Role in Truck Operation

In the context of heavy-duty truck engines, the Turbo Oil Supply Tube plays a significant role in turbo lubrication and performance. It ensures that the turbocharger receives a steady supply of oil, which is crucial for the turbo’s operation under varying load conditions. This consistent lubrication helps in maintaining the turbo’s efficiency, allowing the engine to perform at its best across a wide range of operating conditions 3.

Key Features

The Turbo Oil Supply Tube is designed with several key features that enhance its functionality. It is typically constructed from durable materials that can withstand the high pressures and temperatures within the engine compartment. The design may include reinforced sections to prevent kinking or damage, ensuring a reliable oil flow. Additionally, the tube is engineered to fit precisely within the engine’s layout, minimizing the risk of leaks or disconnections 4.

Benefits

The advantages of the Turbo Oil Supply Tube include improved turbo reliability, enhanced engine performance, and potential cost savings for fleet operators. By ensuring proper lubrication and cooling of the turbocharger, the tube contributes to the longevity of the turbo system. This can lead to reduced maintenance costs and fewer unplanned downtimes, offering significant benefits in terms of operational efficiency and cost management 5.

Installation and Compatibility

For the proper installation of the Turbo Oil Supply Tube, it is important to follow manufacturer guidelines to ensure compatibility with Cummins engines. This may involve specific fitting procedures or the use of compatible seals and connectors. Ensuring the tube is correctly installed will help in maintaining the integrity of the oil supply system and the overall performance of the turbocharger 6.

Maintenance and Troubleshooting

Routine maintenance practices for the Turbo Oil Supply Tube include regular inspections for signs of wear, leaks, or damage. It is also important to ensure that the tube is securely connected and that there are no obstructions in the oil flow path. Troubleshooting common issues may involve checking for proper oil pressure, inspecting connections for leaks, and verifying the tube’s condition. Addressing these issues promptly can help in maintaining the optimal performance of the turbo system 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. The company’s product offerings cater to various sectors, including heavy-duty trucking, construction, agriculture, and power generation, among others 8.

Turbo Oil Supply Tube (Part 5367475) Compatibility with Cummins Engines

The Turbo Oil Supply Tube, identified by the part number 5367475, is a critical component in the lubrication system of certain Cummins engines. This part is designed to ensure that the turbocharger receives an adequate and consistent supply of oil, which is essential for its proper operation and longevity.

B5.9 CM2670 B139 and B166C Engines

The Turbo Oil Supply Tube is compatible with the B5.9 CM2670 B139 and B166C engines. These engines are part of the Cummins B-Series lineup, known for their robust design and reliability in various industrial and commercial applications. The part number 5367475 fits seamlessly into the oil supply system of these engines, ensuring that the turbocharger operates efficiently under varying conditions.

QSB5.9 CM2880 B139 Engine

Similarly, the Turbo Oil Supply Tube is also compatible with the QSB5.9 CM2880 B139 engine. This engine is part of the Cummins QSB Series, which is designed for heavy-duty applications, including agricultural, construction, and industrial use. The part number 5367475 is engineered to meet the specific requirements of the QSB5.9 CM2880 B139 engine, providing a reliable and durable solution for maintaining the turbocharger’s lubrication.

Installation and Maintenance

When installing the Turbo Oil Supply Tube in any of these engines, it is crucial to follow the manufacturer’s guidelines to ensure proper fitment and function. Regular maintenance checks should be performed to verify that the tube is free from leaks, cracks, or other forms of damage that could compromise its performance. Proper installation and maintenance of this part are essential for the overall health and efficiency of the engine’s turbocharger system 9.

Role of Part 5367475 Turbo Oil Supply Tube in Engine Systems

The Turbo Oil Supply Tube, identified by part number 5367475, is an essential component in the efficient operation of turbocharged engine systems. Its primary function is to deliver pressurized oil to the turbocharger, ensuring that the rotating components within the turbocharger are adequately lubricated and cooled.

Integration with Turbocharger

In the context of a turbocharger, the Turbo Oil Supply Tube connects the engine’s lubrication system to the turbocharger. This connection allows oil to flow from the engine’s oil pump through the tube and into the turbocharger. The oil is then directed to critical areas such as the turbine and compressor bearings, as well as the seals, to reduce friction and wear 10.

Interaction with Plumbing

The Turbo Oil Supply Tube is part of the engine’s oil plumbing system. It interfaces with various oil lines and passages within the engine block and turbocharger housing. Proper installation and maintenance of this tube are vital to prevent oil leaks and ensure consistent oil pressure is maintained throughout the system 11.

Ensuring System Efficiency

The efficiency of the Turbo Oil Supply Tube directly impacts the performance and longevity of the turbocharger. By maintaining a steady supply of oil, it helps in dissipating heat generated by the high-speed rotation of the turbine and compressor. This cooling effect is essential in preventing overheating, which can lead to component failure 12.

Maintenance Considerations

Regular inspection of the Turbo Oil Supply Tube is recommended to identify any signs of wear, corrosion, or blockages. Ensuring that the tube is free from obstructions and securely connected to both the engine and turbocharger is key to maintaining optimal engine performance 13.

Conclusion

In summary, the Turbo Oil Supply Tube plays a significant role in the lubrication and cooling of turbochargers, interfacing seamlessly with the engine’s oil system to support efficient and reliable operation. Proper installation, maintenance, and understanding of its function are crucial for maximizing the performance and longevity of turbocharged engine systems 14.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Cummins Inc. (n.d.). ISB6.7 CM2250, Bulletin Number 4022262, Owners Manual.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Cummins Inc. (n.d.). ISB6.7 CM2250, Bulletin Number 4022262, Owners Manual.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins official website.

↩ -

Cummins Inc. (n.d.). ISB6.7 CM2250, Bulletin Number 4022262, Owners Manual.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Cummins Inc. (n.d.). ISB6.7 CM2250, Bulletin Number 4022262, Owners Manual.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Cummins Inc. (n.d.). ISB6.7 CM2250, Bulletin Number 4022262, Owners Manual.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.