This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5410159 Oil Separator Breather is a component designed to enhance the operation of commercial trucks by managing the ventilation of the engine’s crankcase. This part ensures that the engine operates efficiently by separating oil vapors from the air that is vented from the crankcase, thereby maintaining cleaner air intake and reducing oil contamination 1.

Basic Concepts of Oil Separator Breathers

An oil separator breather is a device that captures and separates oil particles from the air that is expelled from the engine’s crankcase. This process is vital for maintaining the cleanliness of the engine’s air intake system and ensuring that oil does not enter the combustion chamber. The breather operates on the principle of centrifugal force and filtration, where oil particles are separated from the air as it passes through the device 2.

Purpose of the Cummins 5410159 Oil Separator Breather

This Cummins part plays a specific role in the truck’s engine system by managing crankcase ventilation. It ensures that the air expelled from the crankcase is free from oil particles, which helps in maintaining the efficiency of the air intake system and reducing the risk of oil contamination in the engine.

Key Features

The Cummins 5410159 is characterized by its robust design and the use of high-quality materials that ensure durability and efficient performance. Its design incorporates advanced filtration technology to effectively separate oil from air, and it is engineered to withstand the demanding conditions of commercial truck operations.

Benefits of Using an Oil Separator Breather

Incorporating an oil separator breather into a truck’s engine system offers several advantages. It contributes to improved engine efficiency by ensuring cleaner air intake, reduces emissions by minimizing oil contamination, and prolongs engine life by maintaining optimal operating conditions 3.

Installation and Integration

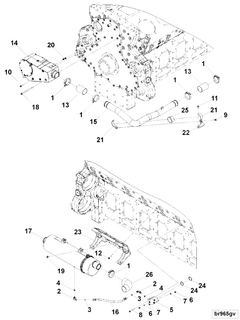

Proper installation of this part is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, taking into consideration the specific requirements of the truck’s engine system. This may include ensuring proper alignment, secure mounting, and correct connection to the crankcase ventilation system.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and efficiency of the Cummins 5410159. This includes periodic inspection for signs of wear or damage, cleaning or replacing filters as necessary, and ensuring that all connections are secure and free from leaks.

Common Issues and Solutions

Frequent problems associated with oil separator breathers may include reduced efficiency due to clogged filters or damage to the device. Practical solutions include regular cleaning or replacement of filters, and inspecting the device for any signs of wear or damage that may require repair or replacement.

Environmental Impact

The use of an oil separator breather, such as the Cummins 5410159, contributes to reducing environmental pollution by minimizing oil contamination in the engine’s air intake system. This results in cleaner emissions and supports overall engine performance, aligning with environmental sustainability goals.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong presence in the commercial truck industry, Cummins is recognized for its innovative products and commitment to quality and performance.

Compatibility of Cummins Oil Separator Breather Part 5410159

The Cummins Oil Separator Breather part number 5410159 is designed to fit seamlessly within the engine systems of the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. This part plays a crucial role in maintaining the integrity of the engine’s lubrication system by preventing contaminants from entering and ensuring that the oil remains clean and efficient.

In the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the Oil Separator Breather part 5410159 is engineered to integrate smoothly with the existing components. Its design ensures compatibility with the specific architecture and requirements of these engines, providing reliable performance and longevity.

The breather is strategically placed within the engine to manage the pressure and flow of gases, effectively separating oil from air and contaminants. This ensures that the oil remains uncontaminated, which is vital for the engine’s overall health and efficiency.

By using the Cummins Oil Separator Breather part 5410159, engine operators can expect enhanced protection against wear and tear, contributing to the longevity and reliability of their QSK95 CM2350 K111 and QSK95 CM2350 K113 engines.

Role of Part 5410159 Oil Separator Breather in Engine Systems

The part 5410159 Oil Separator Breather is an essential component in the efficient operation of various engine systems. It is specifically designed to work in conjunction with the crankcase breather system to manage and control the release of gases and vapors from the crankcase.

Integration with Crankcase Breather System

In the crankcase breather arrangement, the Oil Separator Breather plays a significant role by capturing and separating oil particles from the crankcase vapors. This process ensures that the vapors released into the atmosphere are clean and free from contaminants, which helps in maintaining environmental standards and reducing oil consumption.

Functionality within Breather Kit

When incorporated into a breather kit, the Oil Separator Breather enhances the overall efficiency of the kit. It works alongside other components to provide a comprehensive solution for managing crankcase pressure and emissions. The breather kit, equipped with the Oil Separator Breather, ensures that the engine operates within optimal parameters by preventing the buildup of pressure within the crankcase, which could lead to oil leaks and reduced engine performance.

Contribution to Engine Health

The Oil Separator Breather contributes to engine health by ensuring that the crankcase remains clean and free from excess oil vapors. This not only prolongs the life of the engine but also enhances its performance. By effectively separating oil from the breather gases, it reduces the likelihood of oil contamination in other engine components, such as the intake system, thereby maintaining the engine’s efficiency and reliability.

Environmental and Operational Benefits

From an environmental perspective, the Oil Separator Breather helps in reducing harmful emissions by ensuring that the crankcase vapors are properly treated before being released. Operationally, it aids in maintaining a stable crankcase pressure, which is vital for the proper functioning of the piston rings and overall engine lubrication system.

Conclusion

In summary, the part 5410159 Oil Separator Breather is a vital component that enhances the functionality and efficiency of the crankcase breather system, breather kit, and overall engine operation. Its role in maintaining cleaner air intake, reducing emissions, and prolonging engine life underscores its importance in the maintenance and performance of commercial truck engines.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.