This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

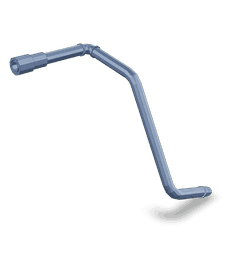

The Lubricating Oil Drain Tube (5521219) by Cummins is a component designed for the maintenance of heavy-duty trucks. Its purpose is to facilitate the efficient drainage of lubricating oil from the engine, ensuring that oil changes are performed smoothly and effectively. This part is integral to maintaining the engine’s lubrication system, which is vital for the longevity and performance of the truck.

Function and Operation

The Lubricating Oil Drain Tube operates as a conduit for oil to flow from the engine’s oil pan to a collection point during an oil change. It plays a role in the oil drainage system by providing a direct path for the oil to exit the engine, which helps in minimizing spillage and ensuring that the oil is drained completely. The tube is typically connected to the oil pan and is opened during maintenance to allow the used oil to be expelled from the engine 1.

Key Features

The 5521219 Lubricating Oil Drain Tube is constructed from materials that offer durability and resistance to the high temperatures and pressures found within an engine environment. Its design includes features that enhance the efficiency of oil drainage, such as a smooth interior to allow for unimpeded oil flow and a secure fitting to prevent leaks. The tube may also incorporate unique attributes, such as a built-in filter to catch debris during drainage or a design that simplifies the reconnection process after an oil change 2.

Benefits of Using the 5521219 Lubricating Oil Drain Tube

Utilizing the 5521219 Lubricating Oil Drain Tube can lead to improved engine performance due to more effective oil management. It simplifies the maintenance process by providing a straightforward method for oil drainage, which can save time during service intervals. Additionally, the tube’s design contributes to the longevity of the engine by ensuring that oil changes are conducted efficiently, which is important for maintaining the engine’s lubrication system 3.

Installation and Compatibility

Proper installation of the Lubricating Oil Drain Tube involves securing it to the oil pan with the appropriate fittings and ensuring a tight seal to prevent leaks. Specific tools may be required for installation, and it is important to follow the manufacturer’s guidelines to ensure correct placement and operation. The tube is designed to be compatible with various Cummins engines, and it may also fit other truck models, depending on the engine’s design and specifications.

Maintenance and Troubleshooting

To maintain the Lubricating Oil Drain Tube, it is important to inspect it regularly for signs of wear or damage, such as cracks or leaks. If any issues are detected, the tube should be replaced to prevent oil leaks and ensure the engine’s lubrication system remains intact. Common problems with oil drain tubes include blockages or detachments, which can be addressed by cleaning the tube or resecuring it, respectively.

Safety Considerations

When working with the Lubricating Oil Drain Tube, it is important to follow safety practices to protect oneself and others. This includes allowing the engine to cool before attempting an oil change to avoid burns from hot oil. Appropriate personal protective equipment, such as gloves and safety glasses, should be worn. Additionally, the truck should be properly secured on a level surface during maintenance to prevent accidents.

Environmental Impact

An efficient Lubricating Oil Drain Tube contributes to environmental stewardship by reducing oil contamination during drainage. This facilitates the easier collection and recycling of used oil, which is beneficial for the environment. Proper disposal and recycling of used oil are important practices that help minimize the ecological footprint of heavy-duty truck maintenance.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to sustainability, Cummins serves customers in approximately 190 countries and territories, providing products and services that drive economic growth and improve the quality of life.

Cummins Engine Compatibility with Lubricating Oil Drain Tube Part 5521219

The Cummins lubricating oil drain tube part number 5521219 is designed to fit a variety of Cummins engines, ensuring efficient oil drainage and maintenance. This part is integral to the engine’s oil system, facilitating the removal of used oil from the engine’s sump.

B6.7 CM2670 and B164C Engines

The B6.7 CM2670 and B164C engines are part of Cummins’ lineup that benefits from the 5521219 oil drain tube. This part is engineered to seamlessly integrate with the oil pan design of these engines, providing a reliable path for oil to exit the sump during oil changes. The precision fitment of this drain tube ensures that oil is effectively removed, minimizing the risk of oil contamination and extending the engine’s operational life.

QSB6.7 CM850 (CM2850) and QSB7 CM2880 B117 Engines

Similarly, the QSB6.7 CM850 (CM2850) and QSB7 CM2880 B117 engines also utilize the 5521219 oil drain tube. These engines, known for their robust performance and reliability, are equipped with an oil pan that is specifically designed to accommodate this drain tube. The compatibility of the 5521219 with these engines ensures that the oil drainage process is efficient and hassle-free, contributing to the overall maintenance and longevity of the engine.

The 5521219 oil drain tube is a critical component for these engines, facilitating the removal of used oil and supporting the engine’s maintenance schedule. Its design and fitment are tailored to the specific requirements of each engine model, ensuring optimal performance and reliability.

Role of Part 5521219 Lubricating Oil Drain Tube in Engine Systems

In the context of engine systems, the lubricating oil drain tube (part 5521219) serves a significant function in maintaining the efficiency and longevity of the engine. This component is integral to the oil management system, ensuring that used oil is effectively drained from the crankcase, thereby facilitating regular oil changes and maintaining optimal lubrication conditions.

The lubricating oil drain tube interfaces directly with the crankcase, which is a vital component of the engine. The crankcase houses the crankshaft and connecting rods, and it is essential for the structural integrity and operation of the engine. As the engine operates, the crankcase accumulates used oil, which must be periodically drained to prevent contamination and ensure that fresh oil can circulate effectively.

The drain tube is designed to provide a secure and efficient pathway for the oil to exit the crankcase. When an oil change is performed, the drain tube allows the technician to direct the flow of used oil into a collection container, minimizing mess and ensuring that the oil is properly disposed of or recycled. This process is fundamental to the maintenance routine of any engine, as it directly impacts the engine’s performance and durability.

Additionally, the proper functioning of the lubricating oil drain tube ensures that the crankcase breather system operates efficiently. The crankcase breather allows gases to escape from the crankcase, preventing pressure build-up that could lead to leaks or damage. By ensuring that the crankcase is free of excess oil, the drain tube supports the breather system, contributing to a balanced and well-maintained engine environment.

Conclusion

In summary, the lubricating oil drain tube (part 5521219) plays a supportive yet essential role in the engine’s oil management system. Its integration with the crankcase and breather system underscores its importance in maintaining the overall health and performance of the engine.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.