This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

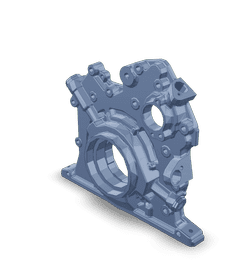

The Cummins Lubricating Oil Pump 5525372 is a specialized component designed to ensure the efficient operation of commercial trucks. Its purpose is to circulate oil throughout the engine, providing necessary lubrication to various moving parts. This part plays a role in maintaining engine performance and longevity by reducing friction and wear between components.

Basic Concepts of Lubricating Oil Pumps

A lubricating oil pump is a device that circulates oil within an engine system to lubricate moving parts. Its primary functions include reducing friction, cooling engine components, and removing contaminants 1. Proper lubrication is vital for the smooth operation of engine components, as it minimizes wear and tear, enhances efficiency, and contributes to the overall longevity of the engine 2.

Purpose of the 5525372 Lubricating Oil Pump

The 5525372 Lubricating Oil Pump is integral to the operation of a truck’s engine. It ensures that oil is consistently delivered to critical components such as bearings, pistons, and camshafts. By maintaining adequate lubrication, this part helps to enhance engine performance, reduce the risk of overheating, and prolong the lifespan of the engine.

Key Features

The 5525372 Lubricating Oil Pump boasts several key features that enhance its performance. Its design incorporates high-quality materials to ensure durability and reliability. The pump is engineered to deliver consistent oil flow, even under varying engine loads and speeds. Additionally, it features precision-machined components to ensure optimal performance and efficiency.

Benefits

Using the 5525372 Lubricating Oil Pump offers several benefits. It contributes to improved engine efficiency by ensuring that all moving parts are properly lubricated. This reduces friction and wear, leading to enhanced reliability and longevity of the engine. Additionally, the pump helps to maintain optimal engine temperature, further contributing to overall performance.

Installation Process

Installing the 5525372 Lubricating Oil Pump requires careful attention to detail. Begin by ensuring the engine is clean and free of debris. Follow the manufacturer’s instructions for removing the old pump and installing the new one. Use the appropriate tools to secure the pump in place and ensure all connections are tight. Finally, perform a thorough inspection to confirm proper installation before starting the engine.

Maintenance Tips

Regular maintenance is crucial for ensuring the longevity and optimal performance of the 5525372 Lubricating Oil Pump. This includes regularly checking oil levels and quality, inspecting for leaks, and ensuring all connections are secure. Additionally, following the manufacturer’s recommended service intervals for oil changes and pump inspections will help maintain efficient operation.

Troubleshooting Common Issues

Common issues with lubricating oil pumps may include insufficient oil pressure, leaks, or pump failure. To address these problems, begin by checking oil levels and ensuring there are no leaks in the system. If oil pressure is low, inspect the pump for blockages or wear. In cases of pump failure, a thorough inspection and possible replacement may be necessary.

Performance Enhancements

While the 5525372 Lubricating Oil Pump is designed for optimal performance, there are potential enhancements that can be made. Upgrading to a higher-capacity pump or incorporating advanced filtration systems can further improve engine performance. Additionally, regular maintenance and timely replacements of worn components can help maintain peak efficiency.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a strong reputation for reliability and performance. The company’s dedication to advancing engine technology ensures that its components, like the 5525372 Lubricating Oil Pump, meet the highest standards of quality and efficiency 3.

Cummins Lubricating Oil Pump Part 5525372 Compatibility

The Cummins lubricating oil pump part number 5525372 is designed to fit seamlessly into several engine models, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of the engines it supports, providing efficient oil circulation and maintaining the necessary lubrication levels.

ISB4.5 CM2350 B104

The ISB4.5 CM2350 B104 engine benefits from the precise engineering of the 5525372 oil pump. This engine, known for its robust performance, relies on the oil pump to maintain its internal components’ health and longevity. The fitment of this part ensures that the engine operates smoothly, with minimal wear and tear.

QSF3.8 CM2350 F107

Similarly, the QSF3.8 CM2350 F107 engine is designed to work in harmony with the Cummins 5525372 oil pump. This engine, which is part of the CM2350 series, also requires efficient oil circulation to maintain its operational efficiency. The oil pump’s design ensures that the engine’s moving parts are adequately lubricated, reducing friction and extending the engine’s lifespan.

Grouping of Engines

Both the ISB4.5 CM2350 B104 and QSF3.8 CM2350 F107 engines are part of the CM2350 series, which underscores the commonality in their design and operational requirements. The 5525372 oil pump is specifically engineered to fit these engines, ensuring that they receive the necessary lubrication to perform optimally. This compatibility highlights the importance of using the correct parts for each engine model, ensuring that the engines maintain their performance and reliability.

Role of the Lubricating Oil Pump (Part 5525372) in Engine Systems

The lubricating oil pump (part 5525372) is integral to maintaining the health and efficiency of various engine components. It ensures a consistent flow of oil to critical areas, facilitating smooth operation and longevity of the engine.

Key Components Benefiting from the Lubricating Oil Pump

-

Crankshaft: The pump delivers oil to the crankshaft bearings, reducing friction and wear. This lubrication is essential for the crankshaft’s rotational movement, which drives the pistons.

-

Camshaft: Oil supplied by the pump lubricates the camshaft bearings and lobes, ensuring precise valve operation and minimizing wear on the cam followers.

-

Connecting Rods: The pump ensures that the connecting rod bearings receive adequate lubrication, which is vital for the smooth transfer of motion from the pistons to the crankshaft.

-

Pistons and Cylinder Walls: Consistent oil flow lubricates the piston rings and cylinder walls, reducing friction and heat, and preventing seizing or scoring.

-

Valve Train: The pump provides oil to the valve train components, including the lifters, rockers, and valve guides, ensuring smooth and reliable valve operation.

-

Timing Chain or Belt: Lubrication of the timing chain or belt components reduces wear and ensures accurate timing, which is essential for engine performance and reliability.

-

Turbocharger (if equipped): In engines with a turbocharger, the oil pump supplies lubrication to the turbocharger bearings, enhancing its efficiency and durability.

-

Oil Filter: The pump maintains oil pressure to ensure the oil filter effectively captures contaminants, keeping the oil clean and prolonging the life of engine components.

By ensuring these components receive consistent lubrication, the lubricating oil pump (part 5525372) plays a significant role in the overall performance, efficiency, and durability of the engine system.

Conclusion

The Cummins Lubricating Oil Pump 5525372 is a critical component in the efficient operation of commercial truck engines. By ensuring consistent oil circulation and lubrication to key engine components, this part enhances engine performance, reduces wear and tear, and prolongs engine lifespan. Regular maintenance and proper installation are essential for maximizing the benefits of this part.

-

Thorsten Boger, Willard Cutler, Reducing Particulate Emissions in Gasoline Engines, SAE International, 2018.

↩ -

Julian Happian-Smith, An Introduction to Modern Vehicle Design, Butterworth-Heinemann, 2002.

↩ -

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems, Wiley, 2022.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.