This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

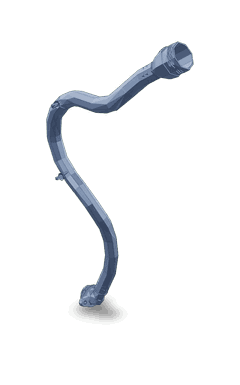

The Cummins 5575416 Oil Filler Tube is a component designed for use in heavy-duty truck engines. Its role is to facilitate the addition of oil to the engine, ensuring that the lubrication system operates effectively. This part is significant in maintaining the engine’s performance and longevity by providing a reliable means for oil replenishment 1.

Purpose and Function

The Oil Filler Tube plays a role in the lubrication system of a truck engine by allowing for the addition of oil. It is positioned to direct oil into the engine’s crankcase, where it is distributed to moving parts. Proper lubrication is vital for reducing friction, wear, and heat generation within the engine. The tube ensures that oil is added in a controlled manner, preventing spills and ensuring that the correct amount of oil is maintained within the engine 2.

Key Features

This Cummins part is constructed with high-quality materials to ensure durability and performance. It features precise threading specifications that allow for a secure fit with the engine’s oil cap. The design includes elements that enhance sealing properties, reducing the risk of oil leaks. The tube is engineered to withstand the pressures and temperatures encountered in heavy-duty truck engines, ensuring reliable operation over time 3.

Benefits

The 5575416 offers several advantages. It provides improved oil flow into the engine, which is crucial for maintaining optimal lubrication. The enhanced sealing properties help to prevent oil leaks, which can lead to engine damage and increased maintenance costs. Compatibility with Cummins engines ensures that the tube integrates seamlessly with the lubrication system, contributing to engine performance and longevity.

Installation and Compatibility

Proper installation of this part is important for ensuring its effectiveness. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and proper function. Compatibility with specific engine models should be verified to ensure that the tube meets the requirements of the engine’s lubrication system.

Maintenance and Troubleshooting

Routine maintenance of the Oil Filler Tube is recommended to ensure optimal performance. This includes checking for signs of wear or damage and ensuring that the sealing surfaces are clean and free from debris. Common issues may include oil leaks or difficulty in adding oil, which can often be addressed by inspecting the tube and sealing surfaces for any issues.

Safety Considerations

When handling and working with the Oil Filler Tube, it is important to follow safety guidelines. This includes wearing appropriate personal protective equipment and ensuring that the engine is cool before attempting any maintenance or installation procedures. Taking precautions during installation, maintenance, and troubleshooting can help prevent accidents or injuries.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its range of engines and components. The company has a history of innovation and commitment to quality, which is reflected in its product offerings. Cummins components, including the 5575416, are designed with a focus on reliability and performance, contributing to the company’s reputation in the market 4.

Conclusion

The Cummins 5575416 Oil Filler Tube is a vital component for maintaining the lubrication system in heavy-duty truck engines. Its design and features ensure reliable oil addition, enhanced sealing properties, and compatibility with Cummins engines. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part and ensuring the longevity and performance of the engine.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB6.7 CM2350 B145. Bulletin Number 5411274.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.