This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

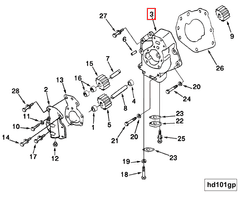

The AR12298 Lubricating Oil Pump Body is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industries. This part is integral to the lubrication system of heavy-duty truck engines, ensuring that engine components receive the necessary lubrication for optimal performance and longevity 1.

Basic Concepts of Lubricating Oil Pump Body

Lubricating oil pump bodies are fundamental to engine lubrication systems. They house the oil pump, which circulates lubricant throughout the engine. Proper lubrication reduces friction between moving parts, minimizes wear, and helps dissipate heat. The efficiency of the lubrication system directly impacts the engine’s performance and durability 2.

Function and Operation

This Cummins part operates by enclosing the oil pump, which draws oil from the sump and pressurizes it before distribution. The pressurized oil is then directed through passages to critical components such as the oil filter, engine bearings, and other moving parts. This ensures that all components receive a consistent supply of lubricant, which is vital for maintaining engine health and performance 3.

Key Features

The AR12298 is designed with several features that enhance its performance and durability. Its construction materials are chosen for their strength and resistance to wear, ensuring longevity. The design also facilitates easy integration with other Cummins engine components, promoting seamless operation within the lubrication system 4.

Benefits

The AR12298 offers several advantages. It contributes to improved lubrication efficiency, which reduces wear on engine components. This, in turn, enhances the overall reliability of the engine. Additionally, efficient lubrication helps maintain optimal engine temperature, contributing to better fuel efficiency and performance.

Troubleshooting and Maintenance

Common issues with the AR12298 may include leaks, reduced oil pressure, or pump failure. Diagnostic procedures involve checking for visible signs of damage, testing oil pressure, and inspecting related components for wear or malfunction. Regular maintenance, such as cleaning and inspecting the pump body, can help prevent issues and ensure continued optimal performance.

Installation and Compatibility

Proper installation of the AR12298 is crucial for its effective operation. It is designed to be compatible with Cummins engines, ensuring a precise fit and function within the engine’s lubrication system. Following manufacturer guidelines during installation helps maintain the integrity of the lubrication system and ensures the part operates as intended.

Performance and Efficiency

The AR12298 plays a role in enhancing the performance and efficiency of heavy-duty trucks. By ensuring consistent and efficient lubrication, it contributes to reduced friction and wear, which can lead to improved fuel efficiency and engine performance. Test data and performance metrics may vary, but the design and function of this component are aligned with achieving optimal engine operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product offerings and long-standing history in the industry underscore its expertise and reliability in manufacturing components like the AR12298 Lubricating Oil Pump Body.

Compatibility

The AR12298 is specifically compatible with the N14 MECHANICAL engines. This compatibility ensures that the oil pump body integrates smoothly with the engine’s design, facilitating efficient oil circulation throughout the engine. The precision engineering of this part guarantees that it meets the stringent requirements of the N14 MECHANICAL engines, providing reliable lubrication and contributing to the overall efficiency and durability of the engine.

Integration with Engine Components

-

Lubricating Oil Pump: The AR12298 body encases the lubricating oil pump, which draws oil from the sump and pressurizes it before distribution. This pressurized oil is then sent to critical engine components such as the crankshaft, camshaft, and valve train.

-

Engine Mounting: Securely mounted within the engine block, the AR12298 body ensures stability and precise alignment of the lubricating oil pump. This mounting is essential for maintaining the pump’s operational efficiency and longevity.

-

Lubrication Circuit: The pump body is a key part of the lubrication circuit, which includes the oil filter, oil galleries, and return paths. It ensures a consistent flow of clean, pressurized oil to all lubricated surfaces, enhancing engine performance and reliability.

-

Oil Sump Connection: The AR12298 body is connected to the oil sump, from which it draws the lubricant. This connection is vital for maintaining the oil level and ensuring that the pump can operate efficiently under various engine loads and speeds.

-

Lubrication of Ancillary Components: Beyond the primary engine components, the AR12298 body also facilitates the lubrication of ancillary components such as the turbocharger, timing chain, and various seals and gaskets, contributing to the overall durability and efficiency of the engine system.

Conclusion

In summary, the AR12298 Lubricating Oil Pump Body plays a significant role in maintaining the lubrication integrity of the engine, ensuring that all moving parts receive the necessary oil to operate smoothly and efficiently. Its design, compatibility, and integration with engine components contribute to the overall performance and reliability of heavy-duty truck engines.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elsevier.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.