This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3693606 Oil Filler Tube is a component designed for use in heavy-duty truck engines. Its primary role is to facilitate the addition of oil to the engine, ensuring that the lubrication system functions correctly. Proper lubrication is vital for the engine’s performance and longevity, making this part an important component of the engine’s maintenance and operation.

Purpose and Function

The Oil Filler Tube provides a pathway for oil to be added to the engine. It is positioned to allow for easy access during oil changes and top-ups. The tube ensures that oil is directed into the engine’s crankcase, where it circulates to lubricate moving parts, reduce friction, and help dissipate heat. This function is essential for maintaining engine efficiency and preventing wear and tear on critical components 1.

Key Features

The Cummins 3693606 is constructed with materials that offer durability and resistance to the high temperatures and pressures found in heavy-duty truck engines. Its design includes features that enhance structural integrity and facilitate easy use. The tube is typically made from high-quality metal or a durable composite material, ensuring it can withstand the rigors of engine operation. Additionally, the tube may include design elements such as a threaded cap to secure the tube in place and prevent leaks 2.

Benefits

This Cummins part offers several advantages. Its design allows for straightforward oil addition, reducing the time required for maintenance tasks. The durable construction ensures a long service life, contributing to the overall reliability of the engine. By ensuring proper lubrication, the tube helps maintain engine performance and extends the lifespan of engine components 3.

Installation and Usage

Proper installation of the Oil Filler Tube is important for ensuring optimal performance and safety. The installation process involves securing the tube in its designated location on the engine, ensuring that it is properly aligned and sealed to prevent leaks. When adding oil, it is important to follow the manufacturer’s guidelines for the correct type and amount of oil to use. This ensures that the lubrication system operates efficiently and that the engine receives the necessary protection 4.

Maintenance and Troubleshooting

Regular maintenance of the Oil Filler Tube is important for ensuring its longevity and efficient operation. This includes checking for signs of wear or damage, ensuring that the cap is securely fastened, and verifying that there are no leaks. Common issues may include leaks due to a loose cap or damage to the tube. Troubleshooting steps may involve tightening the cap, inspecting the tube for damage, or replacing the tube if necessary.

Safety Considerations

When handling and working with the Oil Filler Tube, it is important to observe safety practices to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, and ensuring that the engine is cool before performing maintenance tasks. Additionally, it is important to dispose of used oil properly and follow all manufacturer guidelines for handling and installation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the production of heavy-duty truck components. The company’s commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Compatibility with Specific Engines

The Cummins Oil Filler Tube part number 3693606 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and ease of maintenance. This part is engineered to provide a reliable connection for oil level checking and refilling, which is crucial for maintaining engine health.

X15 CM2350 X116B and X15 CM2450 X134B Engines

The Oil Filler Tube 3693606 is specifically compatible with the X15 CM2350 X116B and X15 CM2450 X134B engines. These engines are part of Cummins’ lineup of high-performance, reliable diesel engines, often used in heavy-duty applications. The tube’s design ensures it fits perfectly with the engine’s architecture, allowing for straightforward installation and maintenance.

Installation and Maintenance

When installing the Oil Filler Tube 3693606 on these engines, it is important to follow the manufacturer’s guidelines to ensure a secure fit. Proper installation is key to preventing oil leaks and ensuring the engine operates at peak efficiency. Regular checks and maintenance of this component can help extend the life of the engine and prevent potential issues related to oil levels.

Importance of the Oil Filler Tube

The Oil Filler Tube is a critical component in the engine’s lubrication system. It allows for easy access to the oil reservoir, enabling users to check oil levels and add oil as needed. This simple yet essential part helps maintain the engine’s lubrication system, which is vital for the engine’s overall performance and longevity.

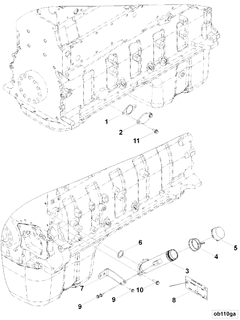

Role of Part 3693606 Oil Filler Tube in Engine Systems

Part 3693606, the Oil Filler Tube, is integral to the arrangement and functionality of the oil fill system within an engine. It serves as a conduit for the introduction of lubricant into the engine’s oil reservoir, typically the oil pan. This part is designed to facilitate a smooth and controlled flow of oil into the system, ensuring that the lubrication process is efficient and effective.

In the context of the oil fill arrangement, the Oil Filler Tube is positioned to align with the engine’s oil cap, allowing for easy access during maintenance routines. Its design often includes features such as baffles or ridges to prevent spills and ensure that oil is directed precisely where it is needed. This is particularly important in high-performance or complex engine systems where the precise management of lubricants can significantly influence engine longevity and performance.

The Oil Filler Tube also interacts with other components of the oil system, such as the oil level sensor and the breather system. By providing a consistent and reliable pathway for oil to enter the engine, it supports the overall integrity of the oil fill process. This, in turn, contributes to the maintenance of optimal oil levels, which is essential for the engine’s moving parts to operate smoothly and with minimal wear.

Conclusion

In summary, Part 3693606 plays a significant role in the oil fill arrangement by ensuring that oil is introduced into the engine system in a manner that is both efficient and controlled, supporting the engine’s lubrication needs and contributing to its overall performance and durability.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2350 K144G. Bulletin Number 5579971.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.