This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

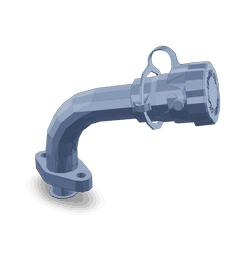

The Cummins 4326249 Oil Filler Tube is a component designed for use in commercial trucks. It plays a role in the engine’s lubrication system by allowing for the addition of oil and helping to maintain proper oil levels. This ensures the engine operates smoothly and efficiently, contributing to the overall performance and longevity of the vehicle 1.

Purpose and Function

The Oil Filler Tube facilitates the process of topping up oil levels, which is a routine maintenance task for engine health. By maintaining the correct oil level, the tube helps ensure that all moving parts within the engine are adequately lubricated, reducing friction and wear 2.

Key Features

This Cummins part is constructed with specific design and construction features that enhance its performance and durability. It is typically made from high-quality materials that can withstand the heat and pressure of the engine environment. The tube features precise threading to ensure a secure fit with the engine’s oil cap, preventing leaks and ensuring that oil is contained within the system. Additionally, the design may include features such as a built-in gasket or O-ring to further enhance the seal and prevent oil loss 3.

Benefits

The 4326249 offers several advantages that contribute to the efficiency and longevity of the engine. Its design allows for easy and convenient oil addition, reducing the time required for maintenance tasks. The reliability of the tube ensures that oil levels are consistently maintained, which is important for engine performance. Furthermore, the durable construction of the tube means it can withstand the rigors of commercial truck operation, providing long-term value and reducing the need for frequent replacements.

Installation Process

Installing the 4326249 requires careful attention to detail to ensure a secure and effective fit. The process typically involves the following steps:

- Ensure the engine is cool and the oil has been allowed to settle.

- Remove the old oil filler tube, if applicable, taking care not to damage surrounding components.

- Clean the area where the new tube will be installed to remove any dirt or debris.

- Align the new tube with the threading on the engine and screw it in place by hand to avoid cross-threading.

- Use a wrench to tighten the tube securely, being careful not to overtighten, which could damage the threading.

- Check for any leaks after installation by running the engine and observing the oil filler tube area.

Maintenance Tips

To ensure the longevity and optimal performance of the Oil Filler Tube, regular maintenance practices should be followed. This includes:

- Inspecting the tube for signs of wear or damage during routine oil changes.

- Ensuring the tube is properly tightened to prevent leaks.

- Cleaning the area around the tube to remove any buildup of dirt or grime that could affect its performance.

Troubleshooting Common Issues

Common problems associated with Oil Filler Tubes include leaks or blockages. To address these issues:

- If a leak is detected, check the tightness of the tube and ensure it is properly seated. If necessary, replace the gasket or O-ring.

- For blockages, ensure that the tube is clear of any obstructions and that the oil cap is correctly aligned.

Safety Considerations

When working with the Oil Filler Tube, it is important to observe safety protocols and precautions. This includes:

- Allowing the engine to cool before attempting any maintenance to avoid burns from hot oil.

- Ensuring proper ventilation when working on the engine to avoid inhaling fumes.

- Using appropriate personal protective equipment, such as gloves and safety glasses, to protect against spills and debris.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a history of innovation and quality in the design and manufacture of automotive components. The company is known for its commitment to producing reliable and efficient parts that contribute to the performance and durability of commercial vehicles.

Compatibility

The Cummins Oil Filler Tube part number 4326249 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal functionality and ease of maintenance. This part is specifically engineered to integrate with the following engine models:

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

The Oil Filler Tube part 4326249 is meticulously crafted to align with the design specifications of the ISX12 engines. Its compatibility with both the ISX12 CM2350 X102 and ISX12 G CM2180 EJ models ensures that it can be used interchangeably across these variants, providing a standardized solution for oil level checking and refilling.

This part’s design accommodates the unique requirements of these engines, ensuring a secure fit and reliable performance. Its application across these models highlights Cummins’ commitment to providing interchangeable parts that maintain the integrity and efficiency of their engine systems.

Role in Engine Systems

The 4326249 Oil Filler Tube is a component in the arrangement of various engine systems, facilitating the oil fill process which is fundamental for the engine’s lubrication and overall performance.

In the context of the oil fill system, the Oil Filler Tube serves as a conduit for introducing oil into the engine. It is strategically positioned to allow for easy access during maintenance routines, ensuring that the oil reaches the sump or oil pan where it is stored before being circulated throughout the engine.

This tube is designed to work in harmony with other components such as the oil cap, which is often threaded onto the Oil Filler Tube to create a sealed environment, preventing oil leaks and contamination. The design of the tube also accommodates the use of a dipstick, which is inserted through the tube to check the oil level, providing mechanics and engineers with a straightforward method to monitor the engine’s lubrication status.

Furthermore, the Oil Filler Tube is engineered to align with the engine’s layout, ensuring that oil is distributed efficiently without causing spillage or mess during the filling process. Its placement is carefully considered in the engine’s arrangement to avoid interference with other components and to ensure that it can be accessed easily for routine checks and refills.

Conclusion

In summary, the 4326249 Oil Filler Tube plays a significant role in the maintenance and operation of engine systems by providing a reliable pathway for oil introduction, contributing to the engine’s longevity and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.