This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

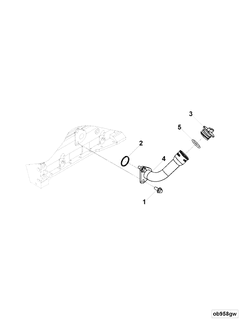

The 4938413 Oil Filler Tube Assembly by Cummins is a component designed to facilitate the addition of oil to heavy-duty truck engines. This assembly is integral to the operation of the engine’s lubrication system, ensuring that the engine receives the necessary lubrication for optimal performance and longevity.

Purpose and Function

The Oil Filler Tube Assembly plays a role in the lubrication system by providing a pathway for oil to be added to the engine. It is designed to maintain proper lubrication levels, which are vital for reducing friction between moving parts, cooling the engine, and removing contaminants. The assembly is engineered to ensure that oil is efficiently directed into the engine, promoting consistent lubrication and supporting the engine’s overall efficiency and reliability 1.

Key Features

This Cummins part is constructed with materials that offer durability and resistance to the harsh conditions within a truck engine environment. Its design includes features that enhance structural integrity and performance. The assembly is made from high-quality materials that can withstand high temperatures and pressures, ensuring a long service life. Additionally, the design may incorporate unique elements such as reinforced seals or corrosion-resistant coatings to further enhance its durability and functionality 2.

Benefits

Using the Oil Filler Tube Assembly offers several advantages. It contributes to improved engine performance by ensuring that the engine maintains optimal lubrication levels. The assembly’s robust construction enhances its durability, reducing the need for frequent replacements. Its design also facilitates ease of use during oil changes, which is beneficial for maintenance routines. Furthermore, the assembly is compatible with Cummins engines, ensuring a precise fit and function within the engine system.

Installation Process

Proper installation of the Oil Filler Tube Assembly is vital for its optimal functionality. The process involves several steps to ensure that the assembly is correctly positioned and secured. It is important to follow manufacturer guidelines to avoid common installation errors that could lead to leaks or improper function. Careful attention to detail during installation will help ensure the longevity and effectiveness of the assembly.

Maintenance and Care

Routine maintenance of the Oil Filler Tube Assembly is important to ensure its continued reliable operation. Regular inspections should be conducted to check for signs of wear or damage. Cleaning the assembly according to manufacturer recommendations can prevent buildup that may affect its function. If any issues are detected during maintenance checks, it may be necessary to consider replacement to maintain engine performance and reliability.

Troubleshooting Common Issues

Common issues with the Oil Filler Tube Assembly may include leaks, fitting problems, or performance concerns. Identifying the source of these issues is the first step in troubleshooting. Leak detection may involve visual inspection or pressure testing. Fitting issues can often be resolved by ensuring that all connections are secure and that the assembly is correctly aligned. Performance concerns should be addressed by verifying that the assembly is free from obstructions and that it is functioning as intended.

Cummins Overview

Cummins Inc. is a leader in the manufacturing of diesel engines and related components, with a strong reputation for quality and innovation in the automotive industry. The company has a history of developing reliable and efficient engine solutions, and its commitment to excellence is evident in the design and performance of its products, including the Oil Filler Tube Assembly 3.

Compatibility of Oil Filler Tube Assembly Part 4938413 with Cummins Engines

The Oil Filler Tube Assembly part number 4938413, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the integrity of the engine’s oil system by providing a secure and leak-proof pathway for oil to enter the engine. Below is a detailed description of the compatibility of this part with various Cummins engines:

4B3.9 and QSB3.9 Engines

The Oil Filler Tube Assembly part 4938413 is compatible with the 4B3.9 and QSB3.9 engines. These engines are part of the Cummins B and QSB series, known for their reliability and efficiency in various applications, including agricultural and industrial machinery.

B4.5 and QSB4.5 Engines

This part also fits the B4.5 and QSB4.5 engines. These engines are part of the Cummins B and QSB series, offering robust performance and durability. The QSB4.5 engines, in particular, are equipped with advanced features such as the CM2250 and CM850 (CM2850) configurations, enhancing their efficiency and power output.

B6.7 and QSB6.7 Engines

The Oil Filler Tube Assembly part 4938413 is suitable for the B6.7 and QSB6.7 engines. These engines are known for their high performance and reliability. The QSB6.7 engines come in various configurations, including CM2250, CM2350 B105, and CM850 (CM2850), each tailored to meet specific performance and efficiency requirements.

QSB7 Engine

Lastly, the part is compatible with the QSB7 engine, specifically the QSB7 CM2880 B117 configuration. This engine is part of the latest generation of Cummins QSB engines, offering advanced technology and superior performance for demanding applications.

By ensuring the correct fitment of the Oil Filler Tube Assembly part 4938413, engine owners can maintain the optimal performance and longevity of their Cummins engines. This part is a critical component in the engine’s oil system, providing a secure and leak-proof connection for oil replenishment.

Conclusion

The 4938413 Oil Filler Tube Assembly is an integral component in the arrangement of various engine systems. Its primary function is to facilitate the oil fill process, ensuring that the engine receives the necessary lubrication for optimal performance and longevity. When integrating this part into the engine system, it is positioned to connect with the oil fill port, which is typically located on the engine cover. This cover is designed to protect the internal components of the engine, including the cylinder block. The cylinder block houses the cylinders, pistons, and other critical moving parts that require consistent lubrication to operate efficiently.

The Oil Filler Tube Assembly is engineered to provide a secure and leak-free pathway for oil to be introduced into the engine. It interfaces with the oil fill port, allowing for easy access during maintenance procedures. The design of the assembly ensures that oil is directed into the engine cover and subsequently into the cylinder block, where it lubricates the moving parts.

In summary, the Oil Filler Tube Assembly plays a significant role in the lubrication system of the engine. It ensures that oil is efficiently delivered to the engine cover and cylinder block, contributing to the overall performance and durability of the engine.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.