This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

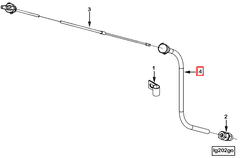

The Oil Gauge Tube, part number 2868790, manufactured by Cummins, is a component designed to facilitate the monitoring of oil levels within the engine’s lubrication system. Its role is significant in ensuring the proper functioning and longevity of commercial trucks by providing accurate oil level readings, which are vital for maintaining optimal engine performance.

Function and Operation

This Cummins part operates as part of the engine’s lubrication system, where it plays a role in monitoring oil levels and pressure. It is connected to the oil gauge, allowing for the transmission of oil level data from the engine to the gauge. This data is crucial for operators to make informed decisions regarding oil changes and engine maintenance, thereby contributing to the efficient operation of the vehicle 1.

Key Features

The Oil Gauge Tube is constructed with specific design and material considerations to enhance its performance and durability. It is typically made from high-quality materials that resist corrosion and wear, ensuring longevity even under demanding operating conditions. The tube’s dimensions are engineered to fit precisely within the engine’s lubrication system, facilitating accurate oil level readings. Additionally, its design may include features that prevent oil leaks and ensure a secure connection to the oil gauge 2.

Benefits

This part offers several advantages, including the provision of accurate oil level readings, which are fundamental for maintaining the engine’s lubrication system. Its reliable performance under various operating conditions ensures that operators receive consistent and trustworthy data. Furthermore, by enabling timely oil changes and maintenance, the Oil Gauge Tube contributes to the overall health and longevity of the engine 3.

Installation and Maintenance

Proper installation of the Oil Gauge Tube is crucial for its effective operation. It should be securely fitted within the engine’s lubrication system, following manufacturer guidelines to ensure a leak-free connection. Regular maintenance, including checks for wear and corrosion, is recommended to ensure optimal performance. Troubleshooting common issues, such as inaccurate readings or leaks, may involve inspecting the tube’s connection to the oil gauge and the condition of the tube itself.

Compatibility and Applications

The Oil Gauge Tube is designed for compatibility with specific Cummins engine models, ensuring it meets the precise requirements of these engines. Its application in commercial trucks underscores its importance in the maintenance and operation of heavy-duty vehicles, where engine health is paramount for performance and reliability.

Safety Considerations

When working with the Oil Gauge Tube, it is important to follow safety precautions and best practices. This includes proper handling to avoid damage to the tube, secure storage to prevent contamination, and adherence to disposal procedures for used or damaged components. These practices help ensure the safety of personnel and the integrity of the engine’s lubrication system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engine components. The company’s commitment to excellence is reflected in its diverse product offerings, which are designed to meet the demanding requirements of commercial applications.

Role of Part 2868790 Oil Gauge Tube in Engine Systems

The Oil Gauge Tube, part number 2868790, is an integral component in the accurate measurement and monitoring of oil levels within an engine system. It works in conjunction with the dipstick and oil level gauge to ensure that the engine operates within optimal lubrication parameters.

Interaction with Dipstick

The Oil Gauge Tube is designed to interface directly with the dipstick. When the dipstick is inserted into the tube, it provides a physical pathway for the dipstick to reach the oil reservoir. This allows for a precise measurement of the oil level. The tube ensures that the dipstick is correctly aligned and that the reading obtained is accurate, which is essential for maintaining proper engine lubrication.

Integration with Oil Level Gauge

In systems where an oil level gauge is employed, the Oil Gauge Tube plays a supportive role. The gauge typically relies on a float or sensor mechanism that is housed within the tube. As the oil level changes, the float or sensor moves accordingly, transmitting data to the gauge. The tube provides a stable and consistent environment for this mechanism to operate, ensuring that the oil level readings are reliable and consistent.

Ensuring Accurate Oil Level Readings

Accurate oil level readings are vital for the health and performance of an engine. The Oil Gauge Tube contributes to this by providing a dedicated pathway for both the dipstick and the oil level gauge sensor. This ensures that there is minimal interference or contamination that could affect the readings. The tube’s design also helps in maintaining the integrity of the oil level measurement system, allowing for timely and accurate assessments of the engine’s lubrication status.

Conclusion

The Oil Gauge Tube, part number 2868790, is a critical component in the maintenance and operation of Cummins engines. Its accurate monitoring of oil levels ensures the engine’s health and longevity, contributing to the efficient operation of commercial trucks. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.