This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

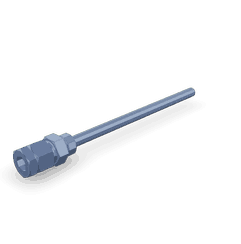

The Cummins 3025589 Oil Gauge Tube is a critical component in commercial truck engines, facilitating the accurate measurement and monitoring of oil levels within the engine’s lubrication system. This ensures efficient and effective operation of the lubrication system.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is integral to an engine’s lubrication system, allowing for the measurement of oil levels by providing a pathway for oil to travel from the oil pan to the oil gauge. This measurement is essential for maintaining proper lubrication, which reduces friction between moving parts, cools the engine, and removes contaminants 1.

Role of the 3025589 Oil Gauge Tube in Truck Operation

In a truck’s engine, the Cummins 3025589 Oil Gauge Tube connects the oil pan to the oil gauge, enabling real-time monitoring of oil levels by the driver. This connection ensures that the oil level remains within the optimal range, contributing to engine performance and longevity, and preventing engine wear and potential failure due to insufficient lubrication 2.

Key Features

This Cummins part is constructed from high-quality materials to withstand the harsh conditions within a truck’s engine compartment. Its design includes precise fittings and connections that ensure a secure and leak-free installation, enhancing its durability and reliability.

Benefits

The Cummins 3025589 Oil Gauge Tube offers improved accuracy in oil level readings, which is crucial for maintaining the engine’s lubrication system within optimal parameters. Its durable construction enhances longevity, reducing the need for frequent replacements. These features contribute to engine efficiency and reliability, supporting the overall performance and durability of the truck 3.

Troubleshooting and Maintenance

Common issues with oil gauge tubes may include leaks, inaccurate readings, or physical damage. Regular maintenance practices, such as inspecting the tube for signs of wear or damage and ensuring all connections are secure, can help prevent these issues. If a problem is detected, it is important to diagnose the issue accurately and take appropriate steps to address it, which may include cleaning, repairing, or replacing the tube as necessary.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the industry, Cummins is committed to producing high-quality automotive components that meet the demanding requirements of commercial vehicles. Their products are known for their reliability, efficiency, and durability, making them a preferred choice for truck manufacturers and operators worldwide.

Oil Gauge Tube (Part 3025589) Compatibility with Cummins Engines

The Oil Gauge Tube, part number 3025589, manufactured by Cummins, is designed to fit seamlessly into several of their engine models. This part is essential for monitoring oil levels and ensuring the engine operates smoothly.

N14 CELECT and N14 CELECT PLUS Engines

The Oil Gauge Tube is compatible with both the N14 CELECT and N14 CELECT PLUS engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The tube ensures accurate oil level readings, which is crucial for maintaining engine health and preventing potential failures.

N14 MECHANICAL Engine

Similarly, the N14 MECHANICAL engine also accommodates the Oil Gauge Tube. This engine variant is favored for its mechanical simplicity and ease of maintenance. The tube’s fitment in this engine ensures that operators can easily monitor oil levels, contributing to the engine’s longevity and performance.

NH/NT 855 Engines

The Oil Gauge Tube is also suitable for the NH/NT 855 engines. These engines are part of Cummins’ lineup of high-performance engines, often utilized in various industrial and transportation applications. The tube’s integration into these engines allows for precise oil level monitoring, which is vital for maintaining optimal engine operation.

By ensuring compatibility across these engines, the Oil Gauge Tube (Part 3025589) provides a reliable solution for oil level monitoring, enhancing the overall efficiency and safety of engine operations.

Role of Part 3025589 Oil Gauge Tube in Engine Systems

The 3025589 Oil Gauge Tube is an essential component in the lubrication system of an engine, facilitating the accurate measurement and monitoring of oil levels. This component interfaces with several other parts to ensure the engine operates efficiently and safely.

Integration with Key Components

-

Cylinder Block and Cylinder Block Cover: The Oil Gauge Tube is typically mounted on the cylinder block cover, which encases the cylinder block. This positioning allows for direct access to the engine’s oil reservoir, ensuring that the oil level can be accurately gauged.

-

Oil Fill Arrangement: The tube works in conjunction with the oil fill arrangement, which includes the oil filler cap and associated passages. This setup allows for the addition of oil when necessary, maintaining optimal lubrication levels within the engine.

-

Dipstick Arrangement: The Oil Gauge Tube is an integral part of the dipstick arrangement. The dipstick is inserted into the tube to check the oil level. The tube guides the dipstick to the correct depth within the oil sump, providing a precise reading.

-

Oil Level Gauge: In systems where an oil level gauge is used, the Oil Gauge Tube serves as a conduit for the gauge’s sensor. This allows for a more accurate and continuous monitoring of oil levels, which is particularly useful in high-performance or complex engine systems.

-

Hand Hole Cover: The tube is often located near the hand hole cover, which provides access to the engine’s internal components for maintenance and inspection. This proximity ensures that the oil level can be checked conveniently during routine maintenance.

-

Oil Gauge Bracket: The Oil Gauge Tube is secured in place by the oil gauge bracket, which ensures stability and proper alignment. This bracket is crucial for maintaining the tube’s position relative to other components, such as the dipstick and cylinder block cover.

Functional Synergy

The Oil Gauge Tube’s role extends beyond simple measurement; it ensures that the oil level is consistently monitored, allowing for timely additions or changes. This component’s accurate readings are vital for preventing engine damage due to insufficient lubrication. Additionally, its integration with the dipstick and oil level gauge enhances the overall reliability and performance of the engine system.

Conclusion

The Cummins 3025589 Oil Gauge Tube plays a vital role in the lubrication system of commercial truck engines by ensuring accurate measurement and monitoring of oil levels. Its durable construction, compatibility with various Cummins engines, and integration with key engine components contribute to engine efficiency, reliability, and longevity. Regular maintenance and troubleshooting are essential to maximize the benefits of this part and ensure optimal engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.