This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3038080 Oil Gauge Tube is a component designed for use in heavy-duty trucks. Its purpose is to measure and display the oil level within the engine, providing vital information that ensures the engine operates within safe parameters. This part plays a role in maintaining engine health and performance by allowing operators to monitor oil levels accurately 1.

Function and Operation

The Cummins 3038080 operates by connecting to the engine’s oil system and utilizing a float mechanism or similar technology to measure the oil level. As the oil level changes, the float moves accordingly, and this movement is translated into a reading on the gauge. This system allows for real-time monitoring of the oil level, ensuring that it remains within the optimal range for engine operation 2.

Key Features

This Cummins part is constructed from durable materials that can withstand the harsh conditions present in heavy-duty truck engines. Its design includes a robust housing that protects the internal components from damage. Additionally, the tube features precise calibration to ensure accurate oil level readings. Unique characteristics may include anti-corrosion coatings and easy-to-read gauge markings 3.

Benefits

Using the 3038080 offers several advantages. It contributes to improved engine performance by ensuring that the oil level is maintained at the correct level, which is important for lubrication and cooling. Enhanced reliability is another benefit, as consistent oil levels help prevent engine wear and damage. Furthermore, the ease of maintenance associated with this gauge tube allows for quicker and more efficient checks and adjustments, reducing downtime.

Installation and Compatibility

Proper installation of the 3038080 involves following manufacturer guidelines to ensure it is securely fitted and correctly aligned with the engine’s oil system. Compatibility with various Cummins engine models is an important consideration, and it is advisable to consult the specific compatibility charts provided by Cummins to ensure the correct fit for your engine.

Maintenance and Troubleshooting

Regular maintenance of the 3038080 includes inspecting for any signs of wear or damage, cleaning the gauge and tube to remove any debris, and ensuring that all connections are secure. Troubleshooting common issues may involve checking for blockages in the tube, verifying the accuracy of the gauge reading, and ensuring that the float mechanism operates smoothly.

Safety Considerations

When working with the 3038080, it is important to follow safety precautions. This includes ensuring that the engine is turned off and cool before beginning any maintenance or inspection procedures. Proper handling and storage of the gauge tube are also important to prevent damage and ensure accurate readings. Disposal should follow local regulations for electronic and mechanical components.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the automotive industry. The company offers a wide range of products designed to meet the needs of various applications, from heavy-duty trucks to industrial equipment.

Role of Part 3038080 Oil Gauge Tube in Engine Systems

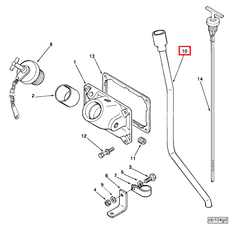

The 3038080 Oil Gauge Tube is an integral component within the engine system, facilitating the accurate measurement and display of oil levels. This tube is strategically positioned to connect the oil gauge to the oil fill arrangement, ensuring a seamless flow of information regarding the engine’s oil status.

Integration with Oil Fill Arrangement

The oil fill arrangement is designed to allow for the addition of oil to the engine, maintaining optimal lubrication levels. The Oil Gauge Tube interfaces directly with this system, drawing oil level data from the oil fill area. This connection ensures that the gauge receives real-time information, allowing for precise monitoring of oil levels within the engine.

Connection to Oil Gauge

The Oil Gauge Tube serves as a vital link between the oil fill arrangement and the oil gauge. By transmitting oil level data to the gauge, it enables engineers and mechanics to monitor the engine’s lubrication status effectively. This direct connection ensures that any fluctuations in oil levels are immediately reflected on the gauge, providing a clear and accurate representation of the engine’s condition.

Ensuring Accurate Oil Level Readings

Accurate oil level readings are important for the proper functioning and longevity of an engine. The Oil Gauge Tube plays a role in this process by ensuring that the oil gauge receives consistent and reliable data. This allows for timely identification of low oil levels, preventing potential engine damage due to insufficient lubrication.

Facilitating Maintenance and Diagnostics

Incorporating the Oil Gauge Tube into the engine system enhances maintenance and diagnostic capabilities. By providing a clear and accurate oil level reading, it allows engineers and mechanics to perform routine checks and identify potential issues before they escalate. This proactive approach to maintenance can significantly extend the lifespan of the engine and improve overall performance.

Conclusion

The Cummins 3038080 Oil Gauge Tube is a vital component in the maintenance and operation of heavy-duty truck engines. By providing accurate and real-time oil level readings, it ensures that engines operate within safe parameters, contributing to their longevity and performance. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.