This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

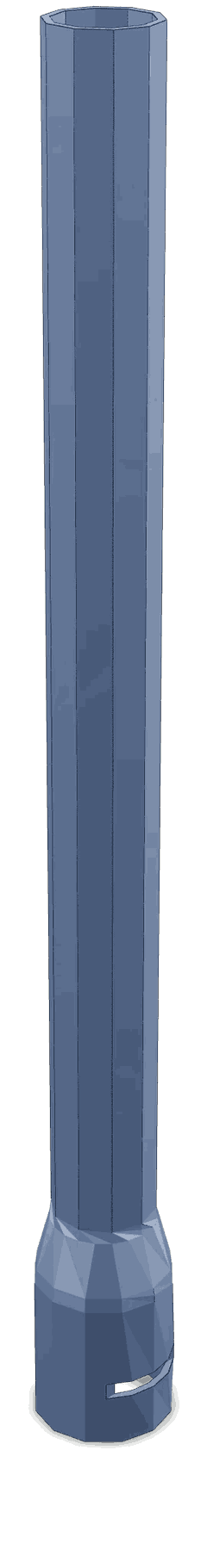

The Cummins 3202271 Oil Gauge Tube is a component designed for use in commercial trucks, specifically within Cummins engines. Its purpose is to facilitate the accurate measurement and monitoring of oil levels within the engine. This part plays a role in the engine cooling system by providing real-time data on oil levels, which is important for timely maintenance and preventing engine damage due to insufficient lubrication 2.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube allows for the measurement of oil levels within an engine. It functions by connecting to the oil reservoir and providing a pathway for oil to travel to the oil gauge, which displays the current oil level. This system is vital for monitoring the engine’s lubrication status, ensuring that there is always an adequate amount of oil circulating to protect moving parts from wear and tear 3.

Purpose of the Cummins 3202271 Oil Gauge Tube

The Cummins 3202271 Oil Gauge Tube serves a specific role in the operation of a truck by ensuring that the engine’s oil levels are accurately monitored. This part aids in maintaining optimal engine performance and longevity by allowing operators to quickly identify when oil levels are low, prompting timely refills or further investigation into potential leaks or consumption issues. Accurate oil level monitoring is a key factor in preventing engine damage and ensuring smooth operation 4.

Key Features

The Cummins 3202271 Oil Gauge Tube is characterized by its robust design and the materials used in its construction, which are selected for durability and precision. This part is engineered to withstand the harsh conditions within a truck engine, ensuring reliable operation over time. Unique attributes of this oil gauge tube may include its precise calibration for accurate oil level readings and its compatibility with specific Cummins engine models, enhancing its functionality within those systems 1.

Benefits of Using the Cummins 3202271 Oil Gauge Tube

Utilizing the Cummins 3202271 Oil Gauge Tube offers several advantages, including improved engine monitoring capabilities. This part contributes to enhanced reliability by ensuring that oil levels are consistently within the optimal range, which is important for engine health. Additionally, by facilitating better maintenance practices through accurate oil level readings, it can lead to potential cost savings by reducing the risk of engine damage due to inadequate lubrication 2.

Installation and Compatibility

Proper installation of the Cummins 3202271 Oil Gauge Tube is important for ensuring its effective operation. Guidelines for installation should be followed closely to ensure compatibility with the specific truck model and engine type. Considerations for installation may include ensuring a secure fit within the engine compartment and proper connection to the oil reservoir and gauge. Compatibility with various truck models is an important factor to consider, ensuring that the oil gauge tube functions correctly within the intended application 3.

Troubleshooting and Maintenance

Common issues related to the Cummins 3202271 Oil Gauge Tube may include inaccurate readings or leaks at the connection points. Troubleshooting these issues can involve checking the connections for tightness and ensuring there are no obstructions within the tube that could affect oil flow. Regular maintenance, such as cleaning the gauge tube and inspecting it for wear or damage, can help ensure its continued reliable operation. Promptly addressing any issues can prevent more significant problems down the line 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation within the commercial truck industry for producing reliable and high-performance engines. The company’s product offerings extend beyond engines to include a wide range of components and systems designed to enhance the efficiency and reliability of commercial vehicles. Cummins’ commitment to innovation and quality has made it a trusted name among fleet operators and manufacturers alike.

Cummins Oil Gauge Tube Part 3202271 Compatibility

The Cummins Oil Gauge Tube part number 3202271 is designed to fit seamlessly within a variety of engine models, ensuring accurate oil level monitoring and contributing to the overall maintenance and performance of the engine. This part is integral to the engine’s health, providing data on oil levels to prevent engine damage due to insufficient lubrication.

K19 Engines

In the K19 engine series, the Oil Gauge Tube part 3202271 is engineered to integrate smoothly with the engine’s design. This part ensures that the oil level readings are precise, allowing for timely maintenance actions and preventing potential engine failures.

QSK19 CM850 MCRS Engines

For the QSK19 CM850 MCRS engines, the Oil Gauge Tube part 3202271 is specifically tailored to fit within the engine’s architecture. This ensures that the oil level monitoring system operates efficiently, providing reliable data to the engine’s control systems. The precision of this part is important in maintaining the high performance and reliability expected from these engines.

MCRS Engines

The Oil Gauge Tube part 3202271 is also compatible with the MCRS engines, where it plays a vital role in the engine’s oil monitoring system. This part’s design ensures that it fits perfectly within the engine’s framework, providing accurate oil level readings and contributing to the engine’s overall efficiency and longevity.

Understanding the Role of Part 3202271 Oil Gauge Tube in Engine Systems

The oil gauge tube (part 3202271) is an integral component in the accurate measurement and monitoring of oil levels within an engine system. This component works in conjunction with several other parts to ensure the engine operates efficiently and safely.

Integration with the Cylinder Block Cover

The cylinder block cover serves as the protective enclosure for the engine’s internal components. The oil gauge tube is typically mounted through this cover, allowing it to extend into the oil sump where the oil level is measured. This setup ensures that the oil gauge tube is securely positioned and protected from external damage, contributing to the overall integrity of the engine’s oil management system.

Connection to the Dipstick Tube

The dipstick tube is another key component in the oil level monitoring process. The oil gauge tube often interfaces with the dipstick tube, providing a pathway for the dipstick to be inserted into the oil sump. This connection allows for both manual and automated oil level checks, ensuring that the engine maintains the correct oil level for optimal performance and lubrication.

Function within the Oil Level Gauge System

The oil level gauge relies on the oil gauge tube to accurately measure the oil level within the sump. The tube acts as a conduit, allowing the gauge to detect the oil level and transmit this information to the engine’s monitoring system. This real-time data is important for maintaining proper oil levels, preventing engine damage due to insufficient lubrication, and ensuring the engine operates within safe parameters.

Conclusion

In summary, the oil gauge tube (part 3202271) plays a role in the engine’s oil management system by interfacing with the cylinder block cover, dipstick tube, and oil level gauge. Its proper installation and function are important for the accurate monitoring and maintenance of oil levels, contributing to the engine’s overall performance and longevity.

-

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.