This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3251882 Oil Gauge Tube is a component designed for use in heavy-duty trucks. It serves a specific function within the engine’s oil system, contributing to the overall performance and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the engine’s efficiency and longevity.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a component that facilitates the measurement of oil levels within an engine. It is connected to the oil gauge on the vehicle’s dashboard, allowing the driver to monitor the oil level in real-time. This monitoring is vital for ensuring that the engine has sufficient lubrication, which is necessary for reducing friction and wear on moving parts 1.

Purpose of the Cummins 3251882 Oil Gauge Tube

The Cummins 3251882 Oil Gauge Tube plays a role in the operation of a truck by providing accurate oil level measurements. This accuracy is important for maintaining optimal engine performance. When the oil level is correct, the engine operates more efficiently, with reduced risk of damage due to insufficient lubrication 2.

Key Features

The Cummins 3251882 Oil Gauge Tube is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high temperatures and pressures present in a heavy-duty truck engine. The tube’s design ensures a secure fit within the engine, minimizing the risk of leaks and ensuring consistent oil level readings.

Benefits of Using the Cummins 3251882 Oil Gauge Tube

Incorporating the Cummins 3251882 Oil Gauge Tube into a truck’s engine system offers several advantages. These include improved accuracy in oil level readings, which contributes to better engine maintenance practices. The tube’s durability and reliability mean it can withstand the demanding conditions of heavy-duty truck operation, providing long-term value 3.

Installation Process

Installing the Cummins 3251882 Oil Gauge Tube requires following a series of steps to ensure it is properly fitted and functions correctly. This process involves preparing the engine compartment, aligning the tube with the oil gauge, and securing it in place. Tools and equipment necessary for installation may include wrenches and sealant, and safety precautions such as wearing protective gloves and eyewear should be observed.

Maintenance and Care

To ensure the Cummins 3251882 Oil Gauge Tube operates optimally, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage, cleaning it as necessary, and replacing it according to the manufacturer’s guidelines or when signs of failure are observed. Proper maintenance helps in preserving the accuracy of oil level readings and the overall health of the engine.

Troubleshooting Common Issues

Common issues with the Cummins 3251882 Oil Gauge Tube may include inaccurate oil level readings or leaks. Troubleshooting these problems involves checking the tube’s fit within the engine, ensuring there are no obstructions or damage, and verifying that all connections are secure. Addressing these issues promptly can help maintain the engine’s performance and prevent more serious problems.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its diesel engines and related components. With a history of innovation and quality, Cummins products are designed to meet the rigorous demands of heavy-duty applications. The company’s reputation for reliability and performance makes its components, like the 3251882 Oil Gauge Tube, a popular choice among truck operators and maintenance professionals.

Compatibility of Oil Gauge Tube Part 3251882 with Cummins Engines

The Oil Gauge Tube part number 3251882, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for maintaining the integrity of the oil monitoring system within the engine, ensuring that oil levels are accurately gauged and displayed to the operator.

ISM CM570 and ISM CM570/870

The ISM CM570 and ISM CM570/870 engines are part of Cummins’ lineup of industrial and marine engines. The Oil Gauge Tube part 3251882 is compatible with these models, providing a reliable method for monitoring oil levels. This compatibility ensures that the engine’s oil system operates efficiently, preventing potential damage from oil starvation or overfilling.

ISM11 CM876 SN and QSM11 CM570

The ISM11 CM876 SN and QSM11 CM570 engines also benefit from the use of the Oil Gauge Tube part 3251882. These engines are known for their robust performance and reliability, and the oil gauge tube plays a critical role in maintaining these standards. By ensuring accurate oil level readings, this part helps in the overall maintenance and longevity of these engines.

M11 CELECT PLUS and M11 MECHANICAL

Lastly, the M11 CELECT PLUS and M11 MECHANICAL engines are equipped with the Oil Gauge Tube part 3251882. These engines are designed for a variety of applications, from heavy-duty trucks to industrial machinery. The oil gauge tube is essential for these engines, providing the necessary data to keep the oil system in optimal condition. This ensures that the engines run smoothly and efficiently, reducing the risk of engine failure due to oil-related issues.

Role of Part 3251882 Oil Gauge Tube in Engine Systems

The part 3251882 Oil Gauge Tube is an integral component in the accurate measurement and monitoring of oil levels within various engine systems. It works in conjunction with several key components to ensure the engine operates efficiently and safely.

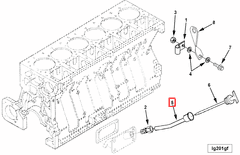

Integration with Cylinder Block Cover

The Oil Gauge Tube is typically mounted on the cylinder block cover, which houses the engine’s internal components. This placement allows the tube to directly interface with the oil within the engine sump, providing a precise measurement of the oil level. The cylinder block cover’s design ensures that the Oil Gauge Tube remains securely in place, minimizing the risk of oil leaks and ensuring consistent readings.

Hand Hole Cover Functionality

Often, the hand hole cover provides access to the engine’s internal components for maintenance and inspection. The Oil Gauge Tube extends through this cover, allowing mechanics to monitor the oil level without needing to remove the cover entirely. This setup streamlines maintenance procedures, reducing downtime and enhancing the overall efficiency of engine servicing.

Oil Fill Arrangement

The Oil Gauge Tube is also an essential part of the oil fill arrangement. It allows for the accurate measurement of oil levels during the refilling process. By providing a clear indication of the oil level, the tube ensures that the engine is neither overfilled nor underfilled, which can lead to performance issues or damage.

Oil Level Gauge Interaction

Finally, the Oil Gauge Tube interacts directly with the oil level gauge, which displays the oil level to the operator. This interaction is vital for real-time monitoring of the engine’s lubrication system. The tube channels the oil level information to the gauge, allowing for immediate detection of any discrepancies, such as low oil levels or potential leaks, thereby enabling prompt corrective action.

Conclusion

The Cummins 3251882 Oil Gauge Tube is a vital component in the maintenance and operation of heavy-duty truck engines. Its accurate measurement of oil levels ensures optimal engine performance and longevity. Regular maintenance and prompt troubleshooting of common issues are essential for preserving the efficiency and reliability of this Cummins part.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018.

↩ -

Automotive Engines Diagnosis Repair and Rebuilding, Tim Giles, Cengage Learning, 2019.

↩ -

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.