This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

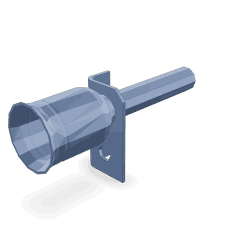

The Cummins 3255108 Oil Gauge Tube is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the accurate measurement of oil levels within the engine, ensuring that the lubrication system operates effectively. This part plays a role in the overall performance and longevity of the engine by providing data on oil levels, which is vital for maintaining optimal engine conditions 1.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube allows for the measurement of oil levels within an engine. It is connected to the oil gauge, which displays the oil level to the operator. The tube extends into the oil sump, where it draws oil up to the gauge. This system enables the operator to monitor the oil level continuously, ensuring that it remains within the required range for efficient engine operation. The oil gauge tube is integral to the engine’s lubrication system, as it helps prevent oil starvation and ensures that all moving parts are adequately lubricated 2.

Purpose and Role in Truck Operation

The Cummins 3255108 Oil Gauge Tube is specifically designed to serve heavy-duty truck engines. Its primary role is to provide accurate oil level readings, which are important for maintaining engine performance and longevity. By ensuring that the oil level is correct, the tube helps prevent engine wear, overheating, and potential damage. Accurate oil level monitoring allows for timely top-ups or changes, which are necessary to keep the engine running smoothly under the demanding conditions typical of heavy-duty truck operations 3.

Key Features

The Cummins 3255108 Oil Gauge Tube is constructed from high-quality materials to ensure durability and reliability. Its design includes precise measurements and fittings to ensure a secure connection within the engine system. The tube is engineered to withstand the high temperatures and pressures present in heavy-duty truck engines, providing consistent performance over time. Additionally, the tube is designed for easy integration with Cummins engines, ensuring compatibility and seamless operation 4.

Benefits of Using Cummins 3255108 Oil Gauge Tube

The Cummins 3255108 Oil Gauge Tube offers several advantages. Its accurate oil level measurement ensures that the engine remains properly lubricated, which is vital for performance and longevity. The tube’s durable construction means it can withstand the rigors of heavy-duty truck use, providing reliable service over time. Additionally, its compatibility with Cummins engines ensures that it integrates seamlessly into the engine system, offering consistent and accurate readings.

Installation and Integration

Installing the Cummins 3255108 Oil Gauge Tube requires careful attention to detail to ensure optimal performance. Begin by locating the oil gauge tube fitting on the engine. Remove the old tube, if present, and inspect the fitting for any damage. Insert the new tube into the fitting, ensuring a secure connection. Connect the tube to the oil gauge, following the manufacturer’s instructions for proper alignment and sealing. Finally, test the gauge to confirm accurate oil level readings and check for any leaks.

Troubleshooting Common Issues

Common issues with oil gauge tubes include inaccurate readings, leaks, and blockages. Inaccurate readings may be due to a faulty gauge or a blockage within the tube. To address this, inspect the tube for obstructions and ensure the gauge is functioning correctly. Leaks can occur at the connections; tightening these or replacing damaged seals can often resolve the issue. Regular maintenance, including inspections and cleaning, can help prevent these problems.

Maintenance Recommendations

To ensure the continued reliable operation of the Cummins 3255108 Oil Gauge Tube, regular maintenance is necessary. Inspect the tube and connections at routine intervals for signs of wear or damage. Clean the tube as needed to remove any debris that may affect its performance. If the tube shows signs of significant wear or if inaccurate readings persist, consider replacing it to maintain engine health. Following these maintenance practices will help ensure the tube continues to provide accurate oil level readings.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality engine components. The company is committed to innovation and excellence, providing reliable and efficient solutions for a wide range of industries, including heavy-duty trucking. Cummins’ dedication to quality and performance is evident in their engine components, including the Cummins 3255108 Oil Gauge Tube.

Oil Gauge Tube (Part 3255108) Compatibility with Cummins Engines

The Oil Gauge Tube, part number 3255108, manufactured by Cummins, is a component in the oil monitoring system of various Cummins engines. This part is designed to provide accurate oil level readings, ensuring the engine operates within safe parameters. Below is a detailed description of its compatibility with specific Cummins engines.

ISM CM570 and ISM CM570/870

The ISM CM570 and ISM CM570/870 engines are part of the Cummins Industrial Series Medium (ISM) lineup. These engines are known for their robust performance and reliability in heavy-duty applications. The Oil Gauge Tube (3255108) fits seamlessly into these engines, providing essential oil level monitoring. Its design ensures compatibility with the engine’s oil system architecture, allowing for precise readings and maintenance.

ISM CM876 and ISM11 CM876 SN

The ISM CM876 and ISM11 CM876 SN engines are also part of the Cummins ISM series, designed for medium-duty applications. The Oil Gauge Tube (3255108) is engineered to fit these engines, ensuring accurate oil level monitoring. This part is crucial for maintaining the engine’s health and performance, as it allows for real-time monitoring of the oil levels, preventing potential engine damage due to low oil.

M11 CELECT PLUS and N14 CELECT PLUS

The M11 CELECT PLUS and N14 CELECT PLUS engines are part of the Cummins CELECT PLUS series, known for their advanced technology and efficiency. The Oil Gauge Tube (3255108) is compatible with these engines, providing reliable oil level monitoring. Its design ensures it fits perfectly within the engine’s oil system, offering precise readings and contributing to the overall efficiency and longevity of the engine.

QSM11 CM570

The QSM11 CM570 engine is another variant in the Cummins lineup, designed for specific applications requiring high performance and reliability. The Oil Gauge Tube (3255108) is engineered to fit this engine, ensuring accurate oil level monitoring. Its compatibility with the QSM11 CM570 engine is crucial for maintaining optimal engine performance and preventing potential issues related to oil levels.

Role of Part 3255108 Oil Gauge Tube in Engine Systems

The Part 3255108 Oil Gauge Tube is an integral component in the oil monitoring system of an engine, facilitating the accurate measurement and display of oil levels. This tube interfaces with several key components to ensure the engine’s lubrication system operates efficiently.

Interaction with Cylinder Block Cover

The Oil Gauge Tube is typically mounted through the Cylinder Block Cover, which encases the engine’s lower section. This positioning allows the tube to extend into the oil sump, where it directly contacts the oil. The tube’s placement ensures that oil levels are measured from a consistent and reliable point within the sump.

Connection to Dipstick

The Oil Gauge Tube is directly connected to the Dipstick, a critical tool used for manual oil level checks. The dipstick slides into the tube, allowing mechanics and engineers to visually inspect the oil level and condition. This interaction ensures that the dipstick provides an accurate reading, reflecting the actual oil level within the sump.

Integration with Hand Hole Cover

Often, the Oil Gauge Tube is accessible through the Hand Hole Cover, a removable panel that provides access to various engine components. This design allows for easy inspection and maintenance of the tube without requiring extensive disassembly of the engine. The hand hole cover’s strategic location facilitates quick checks and adjustments to the oil gauge system.

Role in Oil Fill Arrangement

The Oil Gauge Tube plays a supportive role in the Oil Fill Arrangement. This arrangement includes the oil filler cap and associated passages that allow for oil addition. By providing a precise oil level reading, the tube ensures that the oil fill process is accurately monitored, preventing overfilling or underfilling, which can lead to engine damage.

Contribution to Oil Level Gauge

Finally, the Oil Gauge Tube is an essential component of the Oil Level Gauge system. In engines equipped with an oil level sensor, the tube guides the sensor into the oil sump. This setup allows for real-time monitoring of oil levels, providing data to the engine’s electronic control unit (ECU). The tube ensures that the sensor remains in the optimal position to deliver accurate and consistent oil level readings.

Conclusion

The Cummins 3255108 Oil Gauge Tube is a critical component for maintaining the performance and longevity of heavy-duty truck engines. Its accurate oil level measurement ensures that the engine remains properly lubricated, preventing wear, overheating, and potential damage. The tube’s durable construction and compatibility with Cummins engines make it a reliable choice for heavy-duty applications. Regular maintenance and proper installation are essential to ensure the continued reliable operation of this part.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Vehicle Crash Dynamics, Matthew Huang, CRC Press, 2002.

↩ -

Automotive Engines Diagnosis Repair and Rebuilding, Tim Giles, Cengage Learning, 2019.

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.