This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

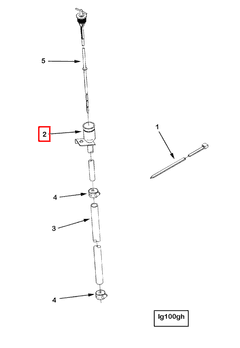

The Cummins Oil Level Gauge Tube, identified by part number 3256458, is a component designed to facilitate the accurate measurement of oil levels within commercial truck engines. Cummins, a well-established name in the engine manufacturing industry, produces this gauge tube as part of its commitment to providing reliable and efficient engine components. This part is integral to the operation of commercial trucks, ensuring that engines receive the proper lubrication needed for optimal performance and longevity.

Basic Concepts of Oil Level Gauge Tubes

An Oil Level Gauge Tube is a component that allows for the measurement of oil levels within an engine. It operates by connecting to the engine’s oil reservoir and providing a pathway for oil to travel to the gauge, which displays the current oil level. This system ensures that operators can monitor oil levels without directly accessing the engine, promoting safety and efficiency. The gauge tube plays a role in the engine system by providing accurate oil level readings, which are vital for maintaining engine health 1.

Purpose of the Oil Level Gauge Tube 3256458

The Oil Level Gauge Tube 3256458 serves a specific function within the operation of a truck. It ensures that the engine maintains proper oil levels, which is fundamental for lubrication and performance. By providing accurate oil level readings, this component helps in preventing engine damage due to low oil levels and ensures that the engine operates within its designed parameters. Proper lubrication is key to reducing friction and wear on engine components, thereby contributing to the overall efficiency and reliability of the truck 2.

Key Features

The Oil Level Gauge Tube 3256458 is characterized by its specific design and construction features that enhance its functionality and durability. It is made from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The precision engineering of this component ensures accurate oil level readings, while its design is tailored to be compatible with Cummins engines. These features contribute to the gauge tube’s effectiveness in providing reliable oil level measurements 3.

Benefits

The advantages of using the Oil Level Gauge Tube 3256458 include improved engine performance through accurate oil level monitoring, enhanced reliability due to its durable construction, and ease of maintenance for fleet operators and mechanics. This component simplifies the process of checking oil levels, reducing the need for frequent engine inspections and potentially lowering maintenance costs. Its design also contributes to the overall efficiency of engine operations by ensuring that oil levels are consistently maintained at optimal levels.

Installation and Maintenance

Proper installation of the Oil Level Gauge Tube 3256458 involves following recommended procedures and using the appropriate tools to ensure a secure fit within the engine system. Maintenance of this component includes regular inspection and cleaning routines to prevent blockages and ensure accurate readings. These practices help in prolonging the life of the gauge tube and maintaining its effectiveness in providing reliable oil level measurements.

Troubleshooting Common Issues

Common problems associated with Oil Level Gauge Tubes may include inaccurate readings or leaks. Troubleshooting these issues involves checking for blockages within the tube, ensuring a secure connection to the engine, and inspecting for any signs of damage or wear. Addressing these problems promptly can help in maintaining the accuracy of oil level readings and the overall health of the engine.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine components and systems. The company has a history of innovation and quality, with a strong reputation for producing reliable and efficient engine parts. Cummins’ commitment to quality is evident in its product offerings, including the Oil Level Gauge Tube 3256458, which is designed to meet the high standards required for commercial truck engines.

Cummins Oil Level Gauge Tube (Part 3256458) Compatibility

The Cummins Oil Level Gauge Tube, identified by part number 3256458, is a critical component in the engine’s lubrication system. This part is designed to provide an accurate reading of the oil level within the engine, ensuring optimal performance and longevity.

N14 Celect Plus

The N14 Celect Plus engine is a robust and reliable power unit, widely used in various heavy-duty applications. The Oil Level Gauge Tube (3256458) fits seamlessly into this engine, allowing for easy monitoring of oil levels. This part is essential for maintaining the engine’s health by preventing oil starvation and ensuring that the lubrication system operates efficiently.

Group Compatibility

The Oil Level Gauge Tube (3256458) is engineered to fit into a range of Cummins engines, providing a standardized solution for oil level monitoring across different engine models. This compatibility ensures that technicians and operators can use a single part for multiple engine types, simplifying maintenance and inventory management.

By integrating this part into the N14 Celect Plus and other compatible engines, Cummins ensures that users can maintain accurate oil level readings, which is crucial for the engine’s overall performance and reliability.

Role of Part 3256458 Oil Level Gauge Tube in Engine Systems

The Oil Level Gauge Tube, identified as part 3256458, is an integral component in the monitoring and maintenance of engine systems. Its primary function is to provide a clear and accurate reading of the oil level within the engine, ensuring that the lubrication system operates efficiently.

Integration with the Oil Level Gauge

The Oil Level Gauge Tube is directly connected to the Oil Level Gauge, which is typically located on the instrument panel of the vehicle. This connection allows for the transmission of the oil level data from the engine to the gauge. The tube acts as a conduit, ensuring that the gauge receives real-time information about the oil level, enabling the driver or mechanic to make informed decisions regarding oil changes or potential issues within the lubrication system.

Interaction with the Engine’s Lubrication System

Within the engine, the Oil Level Gauge Tube is submerged in the oil pan, where it continuously monitors the oil level. As the engine operates, the tube ensures that the oil level remains within the optimal range. If the oil level drops below the minimum threshold, the tube will transmit this information to the gauge, triggering a low oil level warning. This early detection is essential for preventing engine damage due to insufficient lubrication.

Role in Maintenance and Diagnostics

During routine maintenance checks, the Oil Level Gauge Tube plays a significant role. Mechanics rely on the accurate readings provided by the tube to assess the condition of the engine’s lubrication system. If discrepancies are noted, such as fluctuations in the oil level, it may indicate issues such as oil leaks or consumption, prompting further investigation and necessary repairs.

Conclusion

In summary, the Oil Level Gauge Tube (part 3256458) is a vital component in the engine system, facilitating the accurate monitoring of oil levels and contributing to the overall health and performance of the engine. Its integration with the oil level gauge and interaction with the engine’s lubrication system ensure that the engine operates efficiently and reliably. Proper maintenance and timely troubleshooting of common issues are essential for maximizing the effectiveness of this component.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.