This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

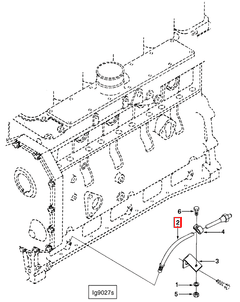

The Cummins 3278410 Oil Gauge Tube is a component designed for use in heavy-duty trucks. It serves a specific function within the engine’s oil system, contributing to the overall performance and reliability of the vehicle. Understanding its purpose and significance is important for maintaining the engine’s efficiency and longevity.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a component that facilitates the measurement of oil levels within an engine. It is connected to the oil gauge on the vehicle’s dashboard, allowing the driver to monitor the oil level in real-time. This monitoring is important for ensuring that the engine has sufficient lubrication, which is necessary for reducing friction and wear on moving parts 1.

Purpose of the Cummins 3278410 Oil Gauge Tube

The Cummins 3278410 Oil Gauge Tube plays a role in the operation of a truck by providing accurate oil level measurements. This accuracy is important for maintaining optimal engine performance. By ensuring that the oil level is within the required range, the tube helps prevent engine damage due to insufficient lubrication. It also aids in the early detection of oil leaks or consumption, allowing for timely maintenance and repairs 2.

Key Features

The Cummins 3278410 Oil Gauge Tube is characterized by its robust design and the materials used in its construction. It is made from high-quality materials that are resistant to corrosion and wear, ensuring durability under the demanding conditions of heavy-duty truck operation. The tube’s design allows for precise oil level readings, contributing to the overall reliability of the oil gauge system 3.

Benefits of Using the Cummins 3278410 Oil Gauge Tube

Using the Cummins 3278410 Oil Gauge Tube offers several advantages. It provides improved accuracy in oil level readings, which is important for maintaining engine health. The tube’s durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, its compatibility with Cummins engines ensures seamless integration and optimal performance 4.

Installation and Compatibility

Proper installation of the Cummins 3278410 Oil Gauge Tube is important for ensuring its effectiveness. It should be installed according to the manufacturer’s guidelines to ensure accurate oil level readings and to prevent leaks. Compatibility with specific truck models should be verified to ensure proper fit and function.

Maintenance and Troubleshooting

To ensure the optimal performance of the Cummins 3278410 Oil Gauge Tube, regular maintenance is recommended. This includes checking for signs of wear or damage and ensuring that the tube is securely installed. Troubleshooting common issues, such as inaccurate readings or leaks, may involve inspecting the tube for blockages or damage and ensuring that it is properly connected to the oil gauge and engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance components for a variety of applications, including heavy-duty trucks. The company’s focus on customer satisfaction and technological advancement ensures that its products, like the Cummins 3278410 Oil Gauge Tube, meet the demanding requirements of modern engines.

Compatibility with Cummins Engines

The Oil Gauge Tube (Part 3278410) is engineered to integrate with several Cummins engine models, ensuring compatibility and ease of installation. Below are the engines where this part is known to fit:

- 6B5.9: This engine model benefits from the precise monitoring capabilities of the Oil Gauge Tube. The part is designed to fit into the engine’s oil system, allowing for accurate readings and timely maintenance.

Installation and Functionality

When installed, the Oil Gauge Tube (Part 3278410) connects to the engine’s oil pan, providing a direct path for oil to flow into the gauge. This setup allows operators to monitor the oil level visually, ensuring that the engine remains adequately lubricated. The tube is typically made from durable materials to withstand the engine’s operating conditions, ensuring longevity and reliability.

Importance in Engine Maintenance

Regular monitoring of oil levels is crucial for maintaining engine performance and longevity. The Oil Gauge Tube (Part 3278410) plays a vital role in this process by providing a clear and accurate indication of the oil level. This helps prevent engine damage due to insufficient lubrication, ensuring that the engine operates smoothly and efficiently.

Grouping of Compatible Engines

For ease of reference, the Oil Gauge Tube (Part 3278410) is compatible with the following Cummins engine groups:

- 6B5.9: This group includes engines that benefit from the precise oil level monitoring provided by the Oil Gauge Tube. The part is designed to fit these engines seamlessly, ensuring compatibility and ease of installation.

Role of Part 3278410 Oil Gauge Tube in Engine Systems

The Part 3278410 Oil Gauge Tube is an integral component in the monitoring and maintenance of engine systems. It facilitates the accurate measurement and display of the oil level within the engine, ensuring that the lubrication system operates within optimal parameters.

Integration with the Oil Level Sensor

The Oil Gauge Tube interfaces directly with the oil level sensor. This sensor relies on the tube to provide a consistent and reliable pathway for the oil to be measured. The tube ensures that the sensor receives an accurate representation of the oil level, which is essential for the sensor to function correctly and provide precise readings to the gauge.

Connection to the Oil Gauge

The Oil Gauge Tube is a vital link between the oil level sensor and the oil gauge. It transmits the information gathered by the sensor to the gauge, where it is converted into a readable format for the operator. This allows for real-time monitoring of the oil level, enabling prompt action to be taken if the level falls below the acceptable range.

Importance in Lubrication System

In the lubrication system, the Oil Gauge Tube plays a significant role by ensuring that the oil level is maintained at the correct level. This is important for the proper functioning of the engine, as inadequate oil levels can lead to increased friction and wear on engine components, potentially resulting in engine failure.

Role in Maintenance and Diagnostics

During maintenance and diagnostic procedures, the Oil Gauge Tube provides valuable data that can help identify potential issues within the lubrication system. By monitoring the oil level through the gauge, mechanics can detect leaks, consumption rates, and other anomalies that may indicate underlying problems.

Contribution to Engine Performance

Ultimately, the Oil Gauge Tube contributes to the overall performance and longevity of the engine. By ensuring that the oil level is consistently monitored and maintained, it helps to prevent damage to engine components and supports efficient operation. This is particularly important in high-performance engines where lubrication is a key factor in achieving optimal power output and reliability.

Conclusion

The Cummins 3278410 Oil Gauge Tube is a critical component in the maintenance and operation of heavy-duty truck engines. Its role in providing accurate oil level readings ensures that the engine remains adequately lubricated, reducing friction and wear on moving parts. The tube’s robust design and durable construction contribute to its long-term reliability, making it a valuable asset in the maintenance of Cummins engines. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Combustion Engine Diagnosis, Rolf Isermann, Springer Vieweg, 2017

↩ -

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023

↩ -

Vehicle Dynamics: Theory and Application, Reza N. Jazar, Springer, 2017

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.