This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

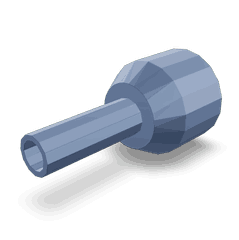

The Oil Gauge Tube Assembly (Part #3281136) by Cummins is a vital component for monitoring engine oil levels in commercial trucks. This assembly ensures the engine operates under optimal conditions by providing accurate oil level readings, which are essential for maintaining engine health and performance 1.

Basic Concepts of Oil Gauge Tube Assembly

The Oil Gauge Tube Assembly operates by communicating the oil level within the engine’s sump to the oil gauge on the vehicle’s dashboard. It consists of a tube that extends into the oil sump, allowing oil to rise to a level that corresponds with the oil level in the sump. This level is then transmitted to the gauge, providing the driver with real-time information on the engine’s oil status. The assembly includes components such as the tube itself, fittings, and possibly a float mechanism, all working together to ensure accurate oil level readings 2.

Purpose and Role in Truck Operation

In commercial truck operation, the Oil Gauge Tube Assembly enables the driver to monitor the engine’s oil levels continuously. This monitoring is vital for engine performance and maintenance, as it allows for timely oil changes and prevents engine damage due to low oil levels. By providing accurate and reliable oil level readings, the assembly contributes to the overall efficiency and longevity of the engine 3.

Key Features

The Oil Gauge Tube Assembly is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. The assembly is engineered to withstand the harsh conditions of commercial truck operation, including temperature fluctuations and vibrations. Its design may include features such as corrosion-resistant coatings and precise fittings to ensure a secure and leak-free connection to the engine 4.

Benefits

Utilizing the Oil Gauge Tube Assembly in commercial trucks offers several benefits. It enhances engine monitoring capabilities, allowing for more informed maintenance decisions. This can lead to improved engine reliability and potentially reduce maintenance costs by preventing engine damage due to inadequate oil levels. Additionally, the assembly’s design contributes to the overall efficiency of the engine, supporting better fuel economy and performance 5.

Installation Process

Installing the Oil Gauge Tube Assembly requires careful attention to detail to ensure proper function and reliability. The process involves securing the tube within the engine’s oil sump, connecting it to the oil gauge, and ensuring all connections are tight and secure. It is important to follow manufacturer guidelines for installation, including the use of specified tools and alignment considerations, to ensure the assembly operates as intended 6.

Troubleshooting Common Issues

Common issues with the Oil Gauge Tube Assembly may include inaccurate oil level readings or leaks at the connection points. Troubleshooting these issues involves checking the assembly for blockages, ensuring all connections are secure, and verifying the gauge’s calibration. In some cases, replacing worn or damaged components may be necessary to restore accurate oil level readings 7.

Maintenance Tips

To ensure the longevity and optimal performance of the Oil Gauge Tube Assembly, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the assembly to remove any debris that may affect its operation, and verifying the accuracy of the oil gauge readings. Adhering to these maintenance practices can help prevent issues and ensure the assembly continues to provide reliable oil level readings 8.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product offerings include engines for on-highway, off-highway, and power generation applications, as well as filtration systems and aftermarket parts. Cummins is dedicated to powering a more prosperous world by providing reliable and efficient power solutions 9.

Compatibility of Cummins Oil Gauge Tube Assembly 3281136

The Cummins Oil Gauge Tube Assembly part number 3281136 is designed to fit seamlessly into specific engine configurations, ensuring accurate oil level readings and maintaining engine health.

6C8.3 Engine

The 6C8.3 engine, known for its robust performance and reliability, is one of the engines that can utilize the Cummins Oil Gauge Tube Assembly 3281136. This part is engineered to integrate smoothly with the 6C8.3 engine, providing essential oil level monitoring capabilities.

ISC CM554 Engine

Similarly, the ISC CM554 engine benefits from the precise functionality of the Cummins Oil Gauge Tube Assembly 3281136. This part ensures that the ISC CM554 engine operates within optimal oil levels, contributing to its overall efficiency and longevity.

Grouping of Engines

The Cummins Oil Gauge Tube Assembly 3281136 is compatible with both the 6C8.3 and ISC CM554 engines, making it a versatile choice for maintaining these specific engine models. Its design allows for easy installation and reliable performance, ensuring that the oil levels are accurately monitored and maintained 10.

Conclusion

The Oil Gauge Tube Assembly (Part #3281136) by Cummins is a critical component for accurate oil level monitoring in commercial truck engines. Its robust design, compatibility with specific engine models, and the benefits it offers in terms of engine maintenance and performance make it an essential part for ensuring the longevity and efficiency of the engine system.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Service Manual (4388708).

↩ -

Cummins Inc. (n.d.). Service Manual (4388708).

↩ -

Cummins Inc. (n.d.). Service Manual (4388708).

↩ -

Cummins Inc. (n.d.). Service Manual (4388708).

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Service Manual (4388708).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.