This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

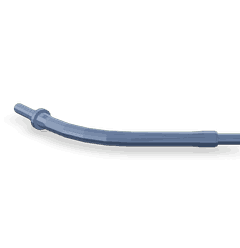

The Cummins 3285712 Oil Gauge Tube is a component designed for use in heavy-duty trucks. Its purpose is to measure the oil level within the engine and transmit this information to the oil gauge on the vehicle’s dashboard. This component plays a role in the engine cooling system by providing accurate oil level readings, which are important for maintaining engine health and performance 1.

Function and Operation

The Cummins 3285712 Oil Gauge Tube operates by dipping into the engine’s oil reservoir and measuring the oil level. It is connected to the oil gauge on the dashboard, which displays the oil level to the driver. This system allows for real-time monitoring of the engine’s oil levels, enabling the driver to take corrective action if the oil level falls below the recommended range. The accurate measurement and transmission of oil levels are important for preventing engine damage due to insufficient lubrication 2.

Key Features

The Cummins 3285712 Oil Gauge Tube is constructed from high-quality materials that ensure durability and resistance to the harsh conditions within an engine. Its design specifications include a precise measurement range and a robust connection to the oil gauge. Unique attributes of this component may include corrosion-resistant coatings and a design that minimizes the risk of leaks, enhancing its performance and longevity 3.

Benefits

Using the Cummins 3285712 Oil Gauge Tube offers several benefits. It provides improved accuracy in oil level measurement, which is important for maintaining optimal engine performance. Timely monitoring of oil levels enhances engine protection by ensuring that the engine is always adequately lubricated. Additionally, the reliability of this component contributes to the overall reliability of truck operations, reducing the risk of unexpected downtime due to engine failure 4.

Installation and Maintenance

Proper installation of the Cummins 3285712 Oil Gauge Tube involves ensuring it is correctly positioned within the engine’s oil reservoir and securely connected to the oil gauge. Necessary tools or equipment may include wrenches for tightening connections and a level to ensure the tube is correctly aligned. Maintenance tips for this component include regular inspection for signs of wear or damage, cleaning the tube and connections to prevent blockages, and replacing the tube if it becomes damaged or inaccurate 5.

Troubleshooting Common Issues

Common issues with the Cummins 3285712 Oil Gauge Tube may include inaccurate oil level readings or leaks. Troubleshooting steps for inaccurate readings may involve checking the tube’s position within the oil reservoir and ensuring it is not blocked or damaged. For leaks, inspecting the connections for tightness and signs of wear can help identify the source of the leak. Solutions may include repositioning the tube, cleaning or replacing connections, or replacing the tube if necessary 6.

Importance of Regular Inspection

Regular inspection and maintenance of the Cummins 3285712 Oil Gauge Tube are important to prevent potential issues and ensure accurate oil level readings. This practice contributes to overall engine health and performance by ensuring the engine is always adequately lubricated. Regular checks can help identify wear, damage, or blockages early, allowing for timely repairs or replacements to maintain the component’s accuracy and reliability 7.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality components for heavy-duty trucks. With a history of innovation and commitment to excellence, Cummins has built a reputation for producing reliable and durable parts that enhance the performance and efficiency of vehicles. The company’s dedication to quality and customer satisfaction is evident in its wide range of products, including the Cummins 3285712 Oil Gauge Tube.

Compatibility with Cummins Engines

-

6B5.9 Engine Series: The Oil Gauge Tube part 3285712 is engineered to fit the 6B5.9 engine series. This series is known for its robust performance and reliability, making it a popular choice in various heavy-duty applications. The tube’s precise fit ensures that it integrates smoothly with the engine’s oil system, providing accurate readings and maintaining the integrity of the engine’s lubrication circuit.

-

Other Cummins Engines: While the primary focus here is on the 6B5.9 series, the Oil Gauge Tube part 3285712 is also compatible with other Cummins engine models. Cummins has a wide range of engines, each designed for specific applications, from construction equipment to marine vessels. The part’s design allows it to fit into the oil systems of these engines, ensuring consistent performance and reliability across different models.

Installation and Functionality

The installation of the Oil Gauge Tube part 3285712 is straightforward, designed to fit into the engine’s oil pan or sump. This placement allows the tube to accurately measure the oil level, providing real-time feedback to the driver. The tube is connected to the oil pressure sensor, which sends signals to the vehicle’s dashboard, alerting the driver if the oil level is too low. This feature is important for maintaining engine health and preventing costly repairs due to engine failure from insufficient lubrication.

Importance of Compatibility

Ensuring that the Oil Gauge Tube part 3285712 is compatible with the specific engine model is important for maintaining the engine’s performance and longevity. Cummins engines are known for their durability and efficiency, and using the correct parts is a key factor in preserving these qualities. The part’s design and materials are chosen to withstand the harsh conditions of engine operation, providing a long-lasting solution for oil level monitoring.

Conclusion

The Cummins Oil Gauge Tube part 3285712 is a vital component for the 6B5.9 engine series and other Cummins engines. Its precise fit and reliable performance make it an important part of the engine’s oil monitoring system, ensuring that the engine operates smoothly and efficiently. Proper installation and maintenance of this part are important for the longevity and performance of Cummins engines.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

Vehicle Crash Dynamics, Matthew Huang, CRC Press, 2002

↩ -

QSB4.5 CM2250 B131, Bulletin Number 4388775, Operation and Maintenance Manual

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

Vehicle Crash Dynamics, Matthew Huang, CRC Press, 2002

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.