This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

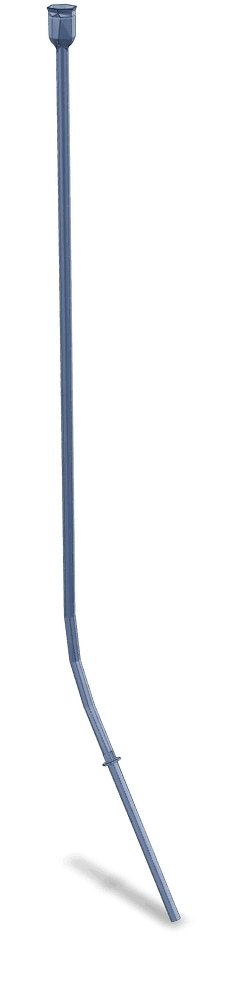

The 3412337 Oil Gauge Tube, manufactured by Cummins, is a component designed for use in heavy-duty truck maintenance and operation. Cummins, a well-established name in the automotive and heavy-duty truck industries, produces this part to ensure reliable and efficient engine performance. The oil gauge tube is integral to the engine’s lubrication system, providing accurate oil level readings that are vital for maintaining optimal engine health 1.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a component within the engine lubrication system that facilitates the measurement of oil levels. It operates by allowing oil to flow into a gauge or sensor, which then provides a reading of the oil level within the engine. Accurate oil level readings are crucial for ensuring that the engine receives adequate lubrication, which is necessary for reducing friction, wear, and heat within the engine components 2.

Purpose of the 3412337 Oil Gauge Tube

The 3412337 Oil Gauge Tube plays a role in the operation of a truck by monitoring oil levels and ensuring the engine receives adequate lubrication. This part helps in maintaining the correct oil level, which is necessary for the efficient operation of the engine. By providing accurate oil level readings, it allows for timely maintenance and prevents potential engine damage due to insufficient lubrication 3.

Key Features

The 3412337 Oil Gauge Tube is constructed with materials that enhance its durability and accuracy. Its design includes elements that ensure a secure fit within the engine, reducing the risk of leaks and inaccurate readings. Unique attributes of this oil gauge tube may include specific threading or connection types that are compatible with Cummins engines, ensuring a precise fit and function.

Benefits

Using the 3412337 Oil Gauge Tube can lead to improved engine performance and enhanced reliability. Accurate oil level readings contribute to better maintenance practices, potentially resulting in cost savings by preventing engine damage and extending the lifespan of the engine components. The durability and precision of this part also contribute to the overall efficiency and reliability of the truck’s engine.

Installation Process

Installing the 3412337 Oil Gauge Tube requires careful attention to ensure a secure and accurate fit. The process involves removing the old oil gauge tube, if present, and installing the new tube in its place. Tools such as wrenches and possibly a torque wrench may be required. It is important to follow the manufacturer’s guidelines for torque specifications to ensure the tube is installed correctly without over-tightening, which could damage the thread or the tube itself.

Troubleshooting Common Issues

Common problems with oil gauge tubes may include inaccurate readings or leaks. Inaccurate readings can often be resolved by ensuring the tube is installed correctly and that there are no obstructions within the tube. Leaks may indicate a loose connection or damage to the tube, requiring reinstallation or replacement. Regular inspection and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

To ensure the longevity and accuracy of the 3412337 Oil Gauge Tube, regular maintenance practices are recommended. This includes cleaning the tube and its connections to remove any debris or buildup that could affect readings. Inspections should be conducted to check for signs of wear or damage, and the tube should be replaced according to the manufacturer’s guidelines or if any issues are detected.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and customer satisfaction in the automotive and heavy-duty truck industries. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications.

Role of Part 3412337 Oil Gauge Tube in Engine Systems

The 3412337 Oil Gauge Tube is a component in the accurate measurement and monitoring of oil levels within an engine system. It interfaces directly with the oil level gauge, providing a conduit for the gauge to accurately read the oil level in the sump or oil pan.

Integration with Oil Level Gauge

The Oil Gauge Tube is designed to work in conjunction with the oil level gauge. It extends from the gauge down into the oil reservoir, allowing the gauge to detect the oil level with precision. This setup ensures that the oil level gauge provides reliable readings, which are vital for maintaining optimal engine performance and preventing potential damage from oil starvation or overfilling.

Functionality in Engine Systems

In engine systems, the Oil Gauge Tube plays a role in the following aspects:

-

Accurate Oil Level Readings: By providing a direct pathway for the gauge to measure the oil level, the tube ensures that the readings are consistent and reliable. This is important for routine maintenance checks and ensuring that the engine operates within safe oil level parameters.

-

Enhanced Engine Monitoring: The precise measurement facilitated by the Oil Gauge Tube allows for better monitoring of oil consumption rates. This can indicate potential issues such as oil leaks or excessive oil consumption, prompting timely interventions.

-

Support for Automated Systems: In modern engine systems equipped with automated oil management features, the Oil Gauge Tube is integral to the feedback loop that informs the system about current oil levels. This enables automated top-ups or alerts when oil levels fall below a specified threshold.

Conclusion

Overall, the 3412337 Oil Gauge Tube is a fundamental component that enhances the reliability and efficiency of engine systems by ensuring accurate and consistent oil level measurements. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Addy Majewski and Hannu Jaskelainen, Diesel Emissions and Their Control: Second Edition, SAE International, 2023.

↩ -

Clive Gifford, Cars Encyclopedia, DK Publishing, 2014.

↩ -

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.