This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

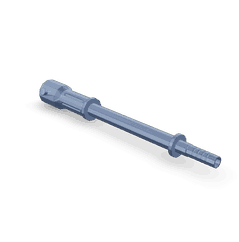

The Cummins 3965029 Oil Gauge Tube is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the accurate measurement and monitoring of engine oil levels. This part is significant in the operation of heavy-duty trucks as it ensures that the engine maintains optimal performance by providing reliable oil level readings 1.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a component within the engine system that allows for the measurement of oil levels. It functions by connecting to the oil reservoir and transferring the oil level information to the gauge on the dashboard. This monitoring is important for maintaining the engine’s lubrication system, which is vital for reducing friction and wear on moving parts 2.

Purpose and Role of the 3965029 Oil Gauge Tube

The Cummins 3965029 Oil Gauge Tube plays a specific role in the operation of a truck by ensuring that the oil level within the engine is consistently monitored. This part aids in maintaining optimal engine performance by providing accurate oil level readings, which allows for timely oil changes and prevents engine damage due to insufficient lubrication 3.

Key Features

The Cummins 3965029 Oil Gauge Tube is characterized by several key features. It is constructed from durable materials that resist corrosion and wear, ensuring longevity. The design includes precise fittings that ensure a secure connection to the oil reservoir. Additionally, it may feature unique characteristics such as enhanced sealing mechanisms to prevent leaks 4.

Benefits of Using the 3965029 Oil Gauge Tube

The advantages provided by the Cummins 3965029 Oil Gauge Tube include increased accuracy in oil level readings, which is crucial for maintaining engine health. Its durable construction ensures longevity, while its reliable performance contributes to the overall efficiency and safety of the vehicle 5.

Installation Process

Proper installation of the Cummins 3965029 Oil Gauge Tube involves several steps. First, the old tube should be removed, taking care to avoid spills. The new tube should then be aligned with the oil reservoir and secured in place using the appropriate fittings. Tools such as wrenches may be required, and safety precautions like wearing gloves and eye protection should be observed 6.

Troubleshooting Common Issues

Common problems associated with oil gauge tubes include inaccurate readings or leaks. Inaccurate readings may be due to a faulty connection or a malfunctioning gauge, while leaks could indicate a damaged tube or loose fittings. Troubleshooting steps may involve checking connections, replacing damaged parts, or recalibrating the gauge 7.

Maintenance Tips

To ensure the longevity and proper functioning of the Cummins 3965029 Oil Gauge Tube, regular maintenance practices should be followed. This includes periodic inspection for signs of wear or damage, ensuring all connections are secure, and replacing the tube if it shows signs of corrosion or leakage 8.

About Cummins

Cummins Inc. is a corporation known for designing, manufacturing, and distributing engines and related technologies. With a history spanning several decades, Cummins has established a reputation for quality and innovation in the automotive industry. Their product range includes engines, filtration systems, and power generation equipment, catering to various sectors such as transportation, construction, and agriculture 9.

Cummins Oil Gauge Tube 3965029 Compatibility

The Cummins Oil Gauge Tube part number 3965029 is designed to fit seamlessly into several engine models, ensuring accurate oil pressure readings and maintaining engine health. This part is compatible with the following engines:

- 6B5.9

- QSB5.9 30 CM550

- QSB5.9 44 CM550

These engines, while differing in specifications and applications, share a common requirement for precise oil pressure monitoring. The Oil Gauge Tube 3965029 is engineered to meet these needs, providing reliable performance across the specified engine models 10.

Role of Part 3965029 Oil Gauge Tube in Engine Systems

The part 3965029 Oil Gauge Tube is an integral component in the oil monitoring system of an engine. It facilitates the accurate measurement and display of the oil level within the engine, ensuring optimal performance and longevity.

Integration with the Dipstick

The Oil Gauge Tube interfaces directly with the dipstick, a slender metal or plastic rod used to check the oil level in the engine. The dipstick is inserted into the tube, which is connected to the oil pan. As the dipstick is withdrawn, it carries a film of oil along its length, providing a visual and tactile indication of the oil level. The Oil Gauge Tube ensures that the dipstick is properly aligned and sealed, preventing oil leaks and ensuring accurate readings 11.

Connection to the Gauge

The Oil Gauge Tube is also connected to the oil level gauge, which is typically located on the instrument panel of the vehicle. The gauge provides a real-time display of the oil level, allowing the driver or mechanic to monitor the oil status continuously. The tube transmits the oil level information from the engine to the gauge, ensuring that the displayed reading is precise and reliable 12.

Ensuring Accurate Oil Level Readings

By maintaining a secure and leak-free connection between the dipstick, oil pan, and gauge, the Oil Gauge Tube plays a significant role in ensuring that the oil level readings are accurate. This accuracy is essential for preventing engine damage due to low oil levels and for maintaining the engine’s efficiency and performance 13.

Conclusion

In summary, the Cummins 3965029 Oil Gauge Tube is a vital component in the oil monitoring system, facilitating the precise measurement and display of the oil level within the engine. Its proper function ensures that the engine operates within safe parameters, contributing to the overall reliability and performance of the vehicle 14.

-

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Service Manual (4367449).

↩ -

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Service Manual (4367449).

↩ -

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ -

Cummins Inc. Service Manual (4367449).

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Service Manual (4367449).

↩ -

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.