This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

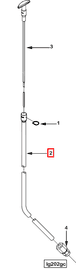

Understanding the Cummins Oil Gauge Tube: Part #4070501

Introduction to Oil Gauge Tubes

Oil gauge tubes are critical components in the engine systems of commercial trucks. They are essential for monitoring oil levels within the engine, ensuring optimal performance and longevity. For engineers and mechanics, understanding the function and importance of an oil gauge tube is vital for maintaining the health and efficiency of commercial vehicles.

The Role of an Oil Gauge Tube in Engines

An oil gauge tube, such as the Cummins part #4070501, is designed to measure the oil level in the engine’s oil pan. This measurement is crucial for maintaining proper lubrication of engine components, preventing overheating, and avoiding engine damage due to insufficient oil. Proper lubrication is vital for reducing friction between moving parts, which minimizes wear and tear, enhances engine performance, and extends the engine’s lifespan 1.

How an Oil Gauge Tube Works

The oil gauge tube is typically a transparent tube that extends from the oil pan to a point where it can be easily read by the driver or mechanic. The tube is filled with oil, and the oil level within the tube corresponds to the oil level in the oil pan. This allows for a visual inspection of the oil level, ensuring that it remains within the safe operating range. The transparency of the tube facilitates quick and accurate assessments, enabling timely interventions if the oil level falls below the recommended threshold 2.

Importance of the Cummins Oil Gauge Tube

Cummins, a renowned manufacturer of heavy-duty engines, produces the part #4070501 oil gauge tube to meet the rigorous demands of commercial truck operations. This component is integral to the engine’s health, providing real-time data on oil levels, which is essential for maintaining engine efficiency and reliability. Cummins’ commitment to quality ensures that their oil gauge tubes are durable, accurate, and designed to withstand the harsh conditions of commercial trucking 3.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are essential for the longevity and effectiveness of the oil gauge tube. Here are some tips for maintaining the Cummins oil gauge tube:

-

Regular Inspections: Check the oil gauge tube for any signs of damage, such as cracks or leaks. A damaged tube can lead to inaccurate readings and potential engine issues. Regular inspections help identify problems early, allowing for prompt repairs and preventing more severe engine damage.

-

Cleanliness: Ensure the oil gauge tube is clean and free from debris. Any obstructions can interfere with the oil level reading. Keeping the tube clean ensures accurate readings and reliable performance.

-

Proper Installation: When replacing the oil gauge tube, ensure it is correctly installed according to the manufacturer’s specifications. Incorrect installation can lead to inaccurate readings and potential engine problems. Following the manufacturer’s guidelines ensures the tube functions as intended.

-

Oil Level Monitoring: Regularly monitor the oil level through the gauge tube. If the oil level is consistently low, investigate potential causes such as leaks or oil consumption issues. Consistent monitoring helps maintain optimal oil levels, ensuring the engine remains well-lubricated and operates efficiently.

Cummins: A Leader in Engine Manufacturing

Cummins is a global leader in the design and manufacture of heavy-duty engines and related technologies. Known for its innovation and reliability, Cummins products are trusted by fleet operators worldwide. The Cummins oil gauge tube is a testament to the company’s commitment to quality and performance. Cummins’ reputation for excellence ensures that their components are built to last, providing reliable performance in demanding applications.

Expert Insights

Understanding the intricacies of the Cummins oil gauge tube and its role in engine operation is crucial for maintaining the health and efficiency of commercial trucks. Proper maintenance and regular inspections can prevent costly engine repairs and ensure the longevity of the vehicle. By providing comprehensive and detailed information on the Cummins oil gauge tube, this article aims to equip engineers, mechanics, truck drivers, and fleet operators with the knowledge they need to effectively manage and maintain this critical component.

Cummins Oil Gauge Tube Part 4070501 Compatibility

The Cummins Oil Gauge Tube part number 4070501 is designed to fit a range of Cummins engines, ensuring accurate oil level monitoring across various models. This part is integral to maintaining engine health by providing real-time feedback on oil levels, which is crucial for preventing engine damage due to insufficient lubrication.

ISM CM570 and ISM CM570/870

The ISM CM570 and ISM CM570/870 engines benefit from the precise oil level readings provided by part 4070501. These engines, known for their robust performance in heavy-duty applications, require reliable oil monitoring to sustain optimal operation. The compatibility of this oil gauge tube ensures that operators can trust the readings, facilitating timely maintenance and reducing the risk of engine failure.

ISM CM876

The ISM CM876 engine also integrates seamlessly with the Cummins Oil Gauge Tube part 4070501. This engine model, favored for its balance of power and efficiency, relies on accurate oil level data to maintain its performance standards. The part’s design ensures it fits perfectly within the engine’s architecture, providing consistent and reliable readings.

M11 CELECT PLUS and M11 MECHANICAL

Both the M11 CELECT PLUS and M11 MECHANICAL engines are compatible with the part 4070501. These engines, known for their versatility and adaptability in various applications, benefit from the precision of this oil gauge tube. The part’s compatibility with these models ensures that operators can maintain optimal oil levels, crucial for the longevity and efficiency of these engines.

QSM11 CM570

The QSM11 CM570 engine is another model that is well-suited to the Cummins Oil Gauge Tube part 4070501. This engine, designed for high-performance applications, requires accurate oil level monitoring to operate at its best. The part’s design ensures it fits perfectly within the engine’s specifications, providing reliable and consistent readings that help maintain engine health.

Understanding the Role of Part 4070501 Oil Gauge Tube in Engine Systems

The part 4070501 Oil Gauge Tube is an essential component in the arrangement of various engine systems, facilitating the accurate measurement and monitoring of oil levels. This component interfaces directly with the oil fill system, ensuring that the oil level is consistently maintained within the optimal range for engine performance and longevity.

Integration with Oil Fill System

In the oil fill system, the Oil Gauge Tube is positioned to allow for the precise measurement of oil volume. It is connected to the oil fill cap, which is the entry point for adding oil to the engine. The tube extends into the oil reservoir, providing a direct pathway for the oil to flow into the engine’s lubrication system. This setup ensures that any added oil is accurately measured and that the oil level can be easily checked during routine maintenance.

Connection to the Oil Level Gauge

The Oil Gauge Tube also plays a significant role in conjunction with the oil level gauge. The gauge relies on the tube to provide a consistent and accurate reading of the oil level within the engine. The tube is typically marked with measurement indicators that align with the gauge, allowing for a clear and precise reading. This integration ensures that mechanics and engineers can quickly assess the oil level, facilitating timely top-ups or changes as necessary.

Ensuring Accurate Oil Level Readings

Accurate oil level readings are vital for the health of the engine. The Oil Gauge Tube ensures that the oil level is measured correctly by providing a direct and unobstructed path for the oil to settle. This prevents air pockets or inconsistencies that could lead to inaccurate readings. The tube’s design allows for the oil to reach a stable level, which is then reflected on the gauge, enabling engineers to make informed decisions regarding oil maintenance.

Facilitating Routine Maintenance

During routine maintenance, the Oil Gauge Tube simplifies the process of checking and adjusting the oil level. Engineers can easily insert the dipstick through the tube to obtain an accurate reading. This component is designed to withstand the pressures and temperatures within the engine, ensuring durability and reliability over time. The consistent and accurate measurements provided by the tube contribute to the overall efficiency and reliability of the engine system.

Conclusion

The Cummins Oil Gauge Tube part #4070501 is a critical component for maintaining the health and efficiency of commercial truck engines. By providing accurate and reliable oil level readings, this part ensures that engines remain well-lubricated, reducing friction, preventing overheating, and extending engine lifespan. Regular maintenance and proper installation of the oil gauge tube are essential for its effective functioning. Cummins’ commitment to quality and innovation ensures that their oil gauge tubes are durable and designed to meet the demanding requirements of commercial trucking. Understanding and maintaining this component is crucial for engineers, mechanics, and fleet operators to ensure the longevity and performance of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.