This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

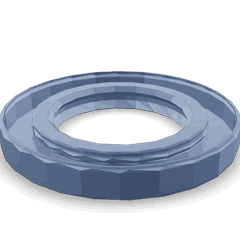

The Cummins 3074482 Oil Seal is a component designed for use in commercial trucks. Its purpose is to prevent oil leakage from specific points within the truck’s engine or transmission system, thereby maintaining the integrity and efficiency of the mechanical system. This seal ensures that oil remains within its designated pathways, which is vital for the lubrication and cooling of moving parts 1.

Basic Concepts of Oil Seals

An oil seal, also known as a rotary shaft seal, is a mechanical device used to prevent leakage of lubricants from rotating equipment. It functions by creating a barrier between the rotating shaft and the stationary housing. The seal’s lip contacts the shaft, and the pressure differential between the lubricant and the atmosphere helps to keep the seal in place and effective. Oil seals are important in mechanical systems because they help maintain the lubrication necessary for the smooth operation of components, reduce wear, and prevent contamination from external particles 2.

Purpose of the Cummins 3074482 Oil Seal

The Cummins 3074482 Oil Seal is specifically designed to address the needs of commercial truck engines. It plays a role in preventing oil leakage at the point where the rotating shaft meets the stationary part of the engine or transmission. By doing so, it helps maintain the proper lubrication of these components, which is necessary for their efficient operation and longevity. The seal also contributes to the overall system integrity by ensuring that oil does not escape into areas where it could cause damage or create a hazardous condition 3.

Key Features

The Cummins 3074482 Oil Seal is constructed with materials and design elements that enhance its performance in demanding environments. It typically features a durable elastomer compound for the sealing lip, which provides resistance to oil, heat, and wear. The design may include reinforcement elements to withstand the pressures and movements associated with truck operation. Unique characteristics such as specific lip configurations or anti-rotation features may be present to improve the seal’s effectiveness and longevity.

Benefits of Using the Cummins 3074482 Oil Seal

Utilizing the Cummins 3074482 Oil Seal in truck operations offers several advantages. Its robust construction contributes to improved durability, allowing it to withstand the rigors of commercial use. The seal’s reliable performance helps ensure consistent lubrication and cooling of engine components, which can lead to enhanced efficiency and reduced maintenance needs. Furthermore, by preventing oil leakage, the seal helps maintain a cleaner operating environment and reduces the risk of oil-related damage to other parts of the truck.

Installation Considerations

When installing the Cummins 3074482 Oil Seal, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes ensuring the mating surfaces are clean and free of imperfections, using the correct tools to install the seal without damage, and verifying that the seal is properly seated. Attention to these details during installation can help prevent issues such as oil leaks or seal failure down the line.

Maintenance and Troubleshooting

Maintaining the Cummins 3074482 Oil Seal involves regular inspection for signs of wear or damage. Common issues may include hardening of the elastomer, cracks, or extrusion of the sealing lip. Troubleshooting methods can include cleaning the seal and its surroundings, checking for proper installation, and replacing the seal if necessary. Adhering to a maintenance schedule and being vigilant for signs of trouble can help extend the life of the seal and ensure continued reliable operation.

Compatibility and Applications

The Cummins 3074482 Oil Seal is designed for use in specific applications within commercial truck environments. It is compatible with certain engine and transmission systems, where it plays a role in maintaining the integrity of the lubrication system. Understanding the seal’s applications and compatibility is important for ensuring it is used in the correct context and for the intended purpose.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer with a history of producing high-quality automotive components. The company is known for its commitment to innovation, reliability, and customer satisfaction. Cummins’ reputation in the industry is built on a foundation of rigorous testing, adherence to quality standards, and a focus on meeting the needs of its customers in the commercial vehicle sector.

Cummins Oil Seal 3074482 Compatibility

The Cummins Oil Seal part number 3074482 is designed to fit a variety of Cummins engines, ensuring a secure seal to prevent oil leaks and maintain optimal engine performance. Below is a detailed description of its compatibility with various Cummins engine models:

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

G101 Series

- G101

ISB Series

- ISB CM550

- ISBE CM800

ISC Series

- ISC CM554

- ISC CM850

ISL Series

- ISL CM554

- ISL9 CM2150 SN

ISX Series

- ISX CM570

N14 Series

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

- QSN14 CM876 N103

QSX15 Series

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

This oil seal is engineered to provide a reliable seal in various engine environments, ensuring that oil remains within the engine system and preventing contamination and wear.

Role of Part 3074482 Oil Seal in Engine Systems

The part 3074482 Oil Seal is instrumental in maintaining the integrity and efficiency of various engine components. Its primary function is to prevent oil leakage, ensuring that the lubricant remains within the system where it is needed most. This seal is particularly significant in the following components:

- Accessory Support: The oil seal ensures that the accessory support remains lubricated, reducing friction and wear on moving parts.

- Alternator Mounting: By sealing the alternator mounting, it helps in maintaining the efficiency of the alternator by preventing oil contamination.

- Base Parts: Integral to the base parts, the oil seal prevents oil from seeping into areas where it could cause damage or reduce efficiency.

- Fan Drive and Fan Support: These components rely on the oil seal to maintain proper lubrication, ensuring smooth operation and longevity.

- Idler Pulley and Idler Top Level Assembly Pulley: The seal is vital in these components to maintain the correct oil levels, reducing wear and tear.

- Lower Engine Gasket Set and Lower Engine Set: The oil seal plays a key role in these sets by preventing oil leakage, which is essential for the gaskets’ integrity and the engine’s overall performance.

- Refrigerant Compressor Mounting: Ensuring that the refrigerant compressor mounting is well-sealed helps in maintaining the compressor’s efficiency and longevity.

- W.P. Repair Kit, Water and Idler Pump, Water Pump, Water Pump and Idler, Water Pump Kit, Water Pump Repair Kit, Water Pump Shaft: In these water-related components, the oil seal is essential for preventing oil contamination in the water systems, ensuring that both systems operate efficiently without interference.

The part 3074482 Oil Seal is a fundamental component in these engine systems, playing a significant role in their maintenance and efficiency.

Conclusion

The Cummins 3074482 Oil Seal is a critical component in the maintenance and efficiency of commercial truck engines. Its role in preventing oil leakage ensures that engine components remain properly lubricated and cooled, contributing to the overall performance and longevity of the engine. Proper installation, maintenance, and understanding of its compatibility with various engine models are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.