This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

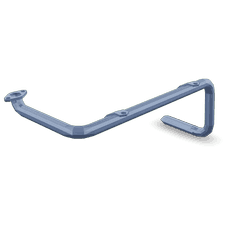

The Cummins 3921992 Oil Suction Connection is a specialized component designed for commercial trucks, playing a crucial role in the engine’s lubrication system. This part facilitates the efficient transfer of oil from the sump to the engine, ensuring the engine’s operational integrity and longevity.

Basic Concepts of Oil Suction Connections

An oil suction connection is integral to the lubrication system of a truck engine, allowing oil to be drawn from the sump and circulated through the engine. This circulation is vital for reducing friction between moving parts, cooling the engine, and removing contaminants 1. The proper function of an oil suction connection is essential for maintaining engine health and ensuring optimal performance.

Purpose of the Cummins 3921992 Oil Suction Connection

The Cummins 3921992 Oil Suction Connection is designed to facilitate the flow of oil from the sump to the engine. It ensures that the engine receives a consistent supply of lubricant, which is necessary for the smooth operation of engine components. By maintaining adequate lubrication, this part contributes to the overall efficiency and reliability of the engine.

Key Features

The Cummins 3921992 Oil Suction Connection is characterized by several key features that enhance its performance and durability. Its design incorporates materials that are resistant to corrosion and wear, ensuring longevity in demanding environments 2. Additionally, the connection is engineered to provide a secure seal, preventing oil leaks and maintaining system integrity.

Benefits

Using the Cummins 3921992 Oil Suction Connection can lead to improved engine lubrication, which in turn supports enhanced engine durability. The consistent supply of oil helps in reducing wear on engine components, potentially contributing to overall engine efficiency 3. Furthermore, the design and materials used in this connection contribute to its reliability and longevity.

Installation Process

Installing the Cummins 3921992 Oil Suction Connection requires following a series of steps to ensure proper integration into the engine system. The process involves preparing the connection area, aligning the connection with the sump, and securing it in place. Tools such as wrenches and sealant may be required, and it is important to observe safety precautions throughout the installation to prevent injury and ensure the connection is correctly installed.

Maintenance Tips

Regular maintenance of the Cummins 3921992 Oil Suction Connection is important for ensuring optimal performance and longevity. This includes periodic inspections for signs of wear or damage, cleaning the connection to remove any buildup, and ensuring that all seals are intact. Adhering to recommended inspection intervals and maintenance procedures can help in identifying potential issues before they lead to more significant problems.

Troubleshooting Common Issues

Common issues that may arise with the Cummins 3921992 Oil Suction Connection include leaks or blockages. Troubleshooting these problems involves inspecting the connection for damage, ensuring that all seals are intact, and checking for any obstructions in the oil flow path. Addressing these issues promptly can help in maintaining the efficiency of the lubrication system and preventing engine damage.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and commercial truck industries, known for its range of engines and components. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance parts. The company’s product range includes engines, filtration systems, and aftermarket parts, catering to a variety of applications in the commercial trucking sector.

Cummins Oil Suction Connection Part 3921992 Compatibility

The Cummins Oil Suction Connection part number 3921992 is designed to fit a variety of Cummins engines, ensuring proper oil flow and lubrication throughout the engine’s operation. This part is crucial for maintaining engine health and performance. Below is a detailed overview of the engines with which this part is compatible.

Compatible Engines

- 6B5.9

- B5.9 CM2670 B166C

- B5.9 G

- B5.9 GAS PLUS CM556

- G5.9

- ISB CM550

- ISB CM850

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B127

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB5.9 CM2880 B115

- QSB5.9 CM2880 B139

- QSB5.9 CM850

- QSB5.9G

Grouping of Compatible Engines

The Cummins Oil Suction Connection part 3921992 is compatible with a broad range of engines, which can be grouped based on their series and specifications:

-

6B5.9 Series

- 6B5.9

-

B5.9 Series

- B5.9 CM2670 B166C

- B5.9 G

- B5.9 GAS PLUS CM556

-

G5.9 Series

- G5.9

-

ISB Series

- ISB CM550

- ISB CM850

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B127

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

-

QSB Series

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB5.9 CM2880 B115

- QSB5.9 CM2880 B139

- QSB5.9 CM850

- QSB5.9G

This comprehensive compatibility ensures that the Oil Suction Connection part 3921992 can be used across multiple engine models, providing a reliable solution for maintaining proper oil flow and engine lubrication.

Role of Part 3921992 Oil Suction Connection in Engine Systems

The 3921992 Oil Suction Connection is an integral component in the lubrication system of an engine, facilitating the efficient circulation of oil. This part interfaces directly with the oil pan, which serves as the reservoir for the engine oil.

When the engine is operational, the oil suction connection draws oil from the oil pan through the use of an oil pump. This connection ensures a secure and leak-free pathway for the oil to be pumped into the engine’s lubrication circuits. The design of the oil suction connection is tailored to fit snugly into the oil pan, preventing any oil leakage which could lead to inefficient lubrication and potential engine damage.

Moreover, the oil suction connection plays a role in maintaining the integrity of the oil filtration process. As oil is suctioned from the pan, it is directed towards the oil filter, where contaminants are removed before the oil is circulated through the engine. This ensures that the engine components receive clean oil, which is essential for reducing wear and tear.

In summary, the 3921992 Oil Suction Connection is a key element in the engine’s oil management system, ensuring that oil is effectively drawn from the oil pan and delivered to the engine components in a controlled and efficient manner.

Conclusion

The Cummins 3921992 Oil Suction Connection is a vital component in the lubrication system of commercial truck engines. Its role in facilitating the efficient transfer of oil from the sump to the engine ensures the engine’s operational integrity and longevity. By understanding its purpose, features, benefits, and maintenance requirements, users can ensure optimal performance and reliability of their engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.