3934942

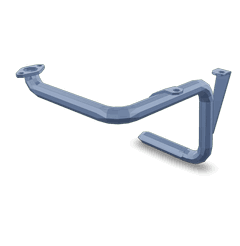

Oil Suction Connection

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3934942 Oil Suction Connection, manufactured by Cummins, is a critical component for the maintenance and operation of heavy-duty trucks. Cummins, a prominent figure in the automotive and heavy-duty truck industry, produces this part to ensure efficient and reliable engine performance. This Cummins part is designed to facilitate the proper functioning of the lubrication system in diesel engines, contributing to the overall performance and longevity of the engine 1.

Basic Concepts of Oil Suction Connection

An Oil Suction Connection is a component within the lubrication system of a diesel engine. Its primary function is to draw oil from the oil pan and deliver it to the engine’s oil pump. This process is vital for maintaining a continuous supply of lubricant to the engine’s moving parts, which helps reduce friction, wear, and heat generation. Proper lubrication is fundamental to the engine’s efficiency and durability, making the Oil Suction Connection a key element in the system 2.

Purpose of the 3934942 Oil Suction Connection

The 3934942 Oil Suction Connection plays a significant role in the operation of a truck by ensuring the effective circulation of oil within the engine. It is responsible for drawing oil from the oil pan and directing it towards the oil pump, which then distributes the oil to various engine components. This continuous oil circulation is crucial for maintaining proper lubrication, which in turn helps protect engine parts from excessive wear and damage. The efficient operation of the 3934942 Oil Suction Connection is therefore important for the reliability and performance of the engine’s lubrication system 3.

Key Features

The 3934942 Oil Suction Connection is characterized by several key features that enhance its performance and durability. Its design is engineered to ensure a secure fit and efficient oil flow. The materials used in its construction are chosen for their strength and resistance to wear, ensuring longevity under the demanding conditions of heavy-duty truck operation. Additionally, the connection may include unique attributes such as reinforced seals or corrosion-resistant coatings, further enhancing its reliability and performance.

Benefits

The advantages provided by the 3934942 Oil Suction Connection include improved engine efficiency, reduced wear on engine components, and enhanced reliability of the lubrication system. By ensuring a consistent supply of oil to the engine, this component helps maintain optimal lubrication, which is crucial for the engine’s smooth operation and longevity. The robust design and high-quality materials used in the 3934942 Oil Suction Connection contribute to its durability and effectiveness in demanding applications.

Installation Process

The proper installation of the 3934942 Oil Suction Connection involves several steps to ensure a secure and effective fit. First, the area around the oil pan should be cleaned to remove any debris or old gasket material. The connection should then be aligned with the oil pan and secured according to the manufacturer’s instructions, using the appropriate tools and equipment. It is important to follow best practices during installation to prevent leaks and ensure the connection is properly sealed. This may include torquing fasteners to the specified levels and inspecting the connection for any signs of damage or misalignment.

Troubleshooting Common Issues

Common problems associated with Oil Suction Connections, such as leaks or blockages, can often be diagnosed and resolved with careful inspection and maintenance. Leaks may be caused by improper installation, damaged seals, or corrosion. Blockages can occur due to debris in the oil or a malfunctioning oil pump. To address these issues, it is important to inspect the connection regularly, clean or replace seals as necessary, and ensure the oil is free of contaminants. In cases of severe damage or malfunction, the Oil Suction Connection may need to be replaced.

Maintenance Tips

Regular maintenance practices are crucial for ensuring the longevity and optimal performance of the 3934942 Oil Suction Connection. This includes periodic inspection of the connection for signs of wear, leaks, or damage. Cleaning the connection and surrounding area can help prevent the buildup of debris and contaminants. Additionally, following the manufacturer’s recommended inspection intervals and maintenance procedures can help identify potential issues before they lead to more significant problems. Proper maintenance of the Oil Suction Connection contributes to the overall reliability and efficiency of the engine’s lubrication system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing high-quality, reliable, and innovative products. The company’s extensive product range and commitment to excellence make it a trusted name among professionals and enthusiasts alike.

Cummins Oil Suction Connection Part 3934942 Compatibility

The Cummins Oil Suction Connection part number 3934942 is designed to be compatible with a variety of Cummins engine models. This part is integral in ensuring that the oil supply system functions correctly, providing lubrication to the engine’s moving parts. Below is a detailed breakdown of the engines with which this part is compatible:

B5.9 Series Engines

- B5.9 CM2670 B166C

- B5.9 G

- B5.9 GAS PLUS CM556

ISB Series Engines

- ISB CM550

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B127

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

QSB Series Engines

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB5.9 CM2880 B139

The compatibility of the Oil Suction Connection part 3934942 across these engines underscores its versatility and importance in maintaining the integrity of the oil supply system. This part is engineered to fit seamlessly within the design specifications of the listed engines, ensuring optimal performance and longevity.

Role of Part 3934942 Oil Suction Connection in Engine Systems

The part 3934942 Oil Suction Connection is an essential component in the lubrication system of an engine. It is designed to facilitate the efficient transfer of oil from the oil pan to the engine’s lubrication system.

Integration with the Oil Pan

The Oil Suction Connection is typically mounted on the oil pan, which serves as the reservoir for the engine oil. This connection point allows the oil pump to draw oil from the pan through a pickup tube. The design ensures a secure and leak-free connection, which is vital for maintaining the integrity of the lubrication system.

Interaction with the Oil Pump

Once the Oil Suction Connection draws oil from the pan, it channels it to the oil pump. The pump then pressurizes the oil and distributes it throughout the engine to lubricate moving parts such as bearings, pistons, and camshafts. This continuous circulation is necessary to reduce friction and wear, ensuring the engine operates smoothly and efficiently.

Ensuring Consistent Oil Flow

The efficiency of the Oil Suction Connection directly impacts the consistency of oil flow within the engine. A well-designed connection minimizes the risk of air ingestion, which can lead to cavitation in the oil pump. This, in turn, ensures a stable supply of pressurized oil to all critical engine components, enhancing overall engine performance and longevity.

Maintenance and Reliability

Regular inspection and maintenance of the Oil Suction Connection are recommended to prevent leaks and ensure optimal performance. Any signs of wear or damage should be addressed promptly to avoid potential engine damage due to insufficient lubrication.

Conclusion

In summary, the 3934942 Oil Suction Connection plays a significant role in the engine’s lubrication system by facilitating the efficient transfer of oil from the oil pan to the oil pump, thereby supporting the engine’s operational reliability and performance. Regular maintenance and proper installation are crucial to ensure the longevity and efficiency of this critical component.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.