This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

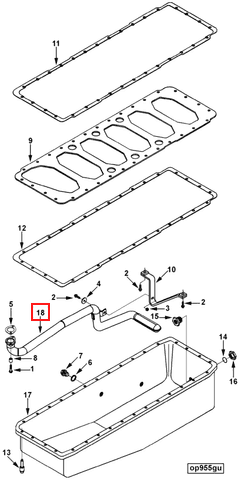

The 3957514 Oil Suction Connection, manufactured by Cummins, is a critical component in the lubrication system of heavy-duty truck engines. Cummins, a leader in the automotive and heavy-duty truck industry, is recognized for its commitment to quality and innovation. This part ensures the efficient operation and longevity of truck engines by facilitating the flow of oil from the oil pan to the engine’s lubrication system 1.

Basic Concepts of Oil Suction Connection

An oil suction connection is designed to draw oil from the oil pan into the engine’s lubrication system, ensuring that all moving parts within the engine receive adequate lubrication. This lubrication is essential for reducing friction, minimizing wear, and maintaining engine performance and longevity 2.

Purpose of the 3957514 Oil Suction Connection

This Cummins part is specifically designed to ensure efficient oil circulation within a truck engine. It plays a role in drawing oil from the oil pan and circulating it throughout the engine, which is necessary for the lubrication of critical engine components and maintaining engine health 3.

Key Features

The 3957514 Oil Suction Connection is characterized by several key features that enhance its performance and reliability. Its design is engineered to withstand the demanding conditions within a heavy-duty truck engine. The materials used in its construction are selected for their durability and resistance to wear. Additionally, it may include unique attributes such as precision machining and high-quality seals to ensure a secure and effective connection.

Benefits

Using the 3957514 Oil Suction Connection offers several benefits. It contributes to improved engine lubrication, which is essential for reducing friction and wear on engine components. This can lead to enhanced engine durability and potentially contribute to fuel efficiency. Additionally, by ensuring reliable oil circulation, it may help reduce maintenance costs associated with engine wear and damage.

Installation Process

Proper installation of the 3957514 Oil Suction Connection involves several steps to ensure a secure and effective fit. Preparatory steps may include cleaning the installation area and inspecting the connection for any damage. Tools required for installation may vary but typically include wrenches and possibly a torque wrench to ensure proper tightening. Best practices include following the manufacturer’s instructions closely and ensuring all connections are tight and secure.

Troubleshooting and Maintenance

Common issues with the 3957514 Oil Suction Connection may include leaks or blockages in the oil flow. Diagnosing these problems involves checking for signs of oil leakage around the connection and ensuring there are no obstructions in the oil path. Maintenance tips to prolong the part’s lifespan include regular inspection for wear or damage, ensuring all connections are tight, and following the manufacturer’s recommended maintenance schedule.

Safety Considerations

When working with the 3957514 Oil Suction Connection, it is important to observe several safety guidelines. These include handling oil with care to avoid spills and contamination, using personal protective equipment such as gloves and safety glasses, and adhering to all manufacturer recommendations for installation and maintenance. Ensuring a safe working environment is crucial when performing any maintenance or repair tasks on engine components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is recognized for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines for on-highway and off-highway applications, as well as power generation and marine solutions. Cummins’ reputation in the automotive and heavy-duty truck industry is built on its dedication to providing reliable and efficient power solutions.

Compatibility of Oil Suction Connection Part 3957514 with Cummins Engines

The Oil Suction Connection part number 3957514, manufactured by Cummins, is designed to fit a variety of Cummins engines. Below is a detailed description of its compatibility across different engine models:

ISC Series Engines

- ISC CM554

- ISC CM850

The Oil Suction Connection part 3957514 is compatible with the ISC series engines, including the ISC CM554 and ISC CM850. This part is integral in ensuring proper oil flow to the engine’s internal components, maintaining optimal lubrication and performance.

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

For the ISL series engines, the part 3957514 is a crucial component for the ISL CM2150, ISL CM554, ISL G CM2180, ISL9 CM2150 SN, and ISL9 CM2250. It ensures that the oil is effectively suctioned and circulated throughout the engine, which is vital for engine longevity and efficiency.

L GAS PLUS Series Engine

- L GAS PLUS CM556

The Oil Suction Connection part 3957514 is also compatible with the L GAS PLUS CM556 engine. This part is essential for maintaining the correct oil pressure and flow, which is crucial for the engine’s operation and performance.

QSL9 Series Engines

- QSL9 CM2250

- QSL9 CM850 (CM2850)

Lastly, the part 3957514 is suitable for the QSL9 CM2250 and QSL9 CM850 (CM2850) engines. It plays a key role in the oil suction mechanism, ensuring that the engine receives the necessary lubrication to function smoothly and efficiently.

Role of Part 3957514 Oil Suction Connection in Engine Systems

The 3957514 Oil Suction Connection is an integral component in the lubrication system of an engine. Its primary function is to facilitate the smooth and efficient transfer of oil from the oil pan to the engine’s lubrication points.

Interaction with the Oil Pan

The Oil Suction Connection is typically mounted on the oil pan, which serves as the reservoir for the engine oil. The connection point allows a suction tube or pipe to be attached, which draws oil from the pan. This setup ensures a consistent supply of oil is available for the engine’s moving parts. The design of the connection must accommodate the fluctuations in oil level within the pan, ensuring a reliable suction even when the oil level is low.

Oil Flow Dynamics

Once the oil is suctioned from the pan via the 3957514 connection, it travels through the suction tube to the oil pump. The oil pump then pressurizes the oil and distributes it throughout the engine to critical components such as the crankshaft, camshaft, pistons, and bearings. The efficiency of this suction process directly impacts the overall lubrication effectiveness, reducing friction and wear on these components.

Maintenance and Efficiency

Regular maintenance of the Oil Suction Connection is essential to ensure it remains free from debris and blockages. Any obstruction in the connection can lead to inadequate oil suction, resulting in insufficient lubrication and potential engine damage. Engineers and mechanics should inspect this component during routine oil changes or engine servicing to ensure its proper function.

Integration with Other Systems

The Oil Suction Connection also interacts with the engine’s sensor systems. Modern engines often incorporate oil level sensors and pressure sensors that monitor the condition of the oil and the efficiency of the lubrication system. The suction connection plays a role in these monitoring processes by ensuring a steady flow of oil, which is essential for accurate sensor readings.

Conclusion

In summary, the 3957514 Oil Suction Connection is a key element in the engine’s lubrication system, working in conjunction with the oil pan and other components to maintain optimal engine performance and longevity. Regular maintenance and proper installation are crucial to ensure the efficient operation of this part and the overall health of the engine.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.