107981

Filler Cap

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To Cummins 107981 Filler Cap

The Cummins 107981 Filler Cap is a critical component in the engine management system of commercial trucks. This article delves into the fundamental concepts related to the filler cap, its purpose, and its role in the operation of a truck. It aims to provide engineers, mechanics, truck drivers, and fleet operators with a thorough understanding of this essential part.

Basic Concepts Related To The Cummins 107981 Filler Cap

A filler cap, also known as a gas cap or fuel cap, is a small but vital component that seals the opening of the fuel tank. Its primary function is to prevent the escape of fuel vapors, which can be harmful to the environment and potentially explosive. The filler cap also prevents contaminants such as dirt, water, and debris from entering the fuel system, which can cause damage to the engine and reduce fuel efficiency 1.

Purpose Of The Cummins 107981 Filler Cap

The Cummins 107981 Filler Cap serves several critical purposes in the operation of a commercial truck:

-

Preventing Fuel Evaporation: The filler cap helps to maintain the fuel level in the tank by preventing the escape of fuel vapors. This is particularly important in commercial trucks, where fuel efficiency is crucial for cost-effectiveness and performance 2.

-

Protecting The Fuel System: By preventing contaminants from entering the fuel system, the filler cap helps to protect the engine and other components from damage. This can lead to longer service life and reduced maintenance costs 3.

-

Ensuring Safety: The filler cap plays a vital role in ensuring the safety of the vehicle and its occupants. By preventing the escape of fuel vapors, it reduces the risk of fire and explosion.

Role Of The Cummins 107981 Filler Cap In Truck Operation

The Cummins 107981 Filler Cap is an integral part of the engine management system in commercial trucks. It works in conjunction with the fuel tank, fuel lines, and fuel injectors to ensure that the engine receives a consistent supply of clean, uncontaminated fuel. This is essential for maintaining optimal performance and fuel efficiency.

Troubleshooting And Maintenance Of The Cummins 107981 Filler Cap

Regular maintenance and troubleshooting of the filler cap are essential for ensuring the continued performance and safety of the vehicle. Here are some tips for maintaining and troubleshooting the Cummins 107981 Filler Cap:

-

Check For Leaks: Regularly inspect the filler cap for signs of leaks or damage. If you notice any leaks, it is essential to replace the filler cap immediately to prevent fuel loss and potential safety hazards.

-

Clean The Filler Cap: Over time, the filler cap can become dirty or clogged with debris. Regularly cleaning the filler cap can help to prevent contamination and ensure that it functions correctly.

-

Replace Worn Or Damaged Parts: If the filler cap or its components are worn or damaged, it is essential to replace them immediately. This can help to prevent further damage to the fuel system and ensure the continued performance of the vehicle.

Cummins Engine Part 107981: Filler Cap Compatibility

The Cummins part 107981, a filler cap, is designed to fit a variety of Cummins engines. Here is a detailed breakdown of its compatibility across different engine models:

6 Series Engines

- 6B5.9

- 6C8.3

G Series Engines

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

ISM Series Engines

- ISM CM570

- ISM CM570/870

K Series Engines

- K19

- K38

- K50

KTA19 Series Engines

- KTA19GC

- KTA19GC CM558

L Series Engines

- L10 MECHANICAL

M Series Engines

- M11 CELECT PLUS

- M11 MECHANICAL

N Series Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

NH/NT Series Engines

- NH/NT 855

QSB Series Engines

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

QSK Series Engines

- QSK19 CM2350 K105

This filler cap is engineered to ensure a secure fit and proper sealing for the specified engines, facilitating maintenance and operational efficiency.

Role of Part 107981 Filler Cap in Engine Systems

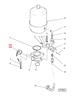

Part 107981 Filler Cap is an integral component in the efficient operation of various engine systems. Its primary function is to facilitate the addition of oil to the engine, ensuring that the lubrication system remains adequately supplied. Here’s how it integrates with the provided components:

-

Arrangement and Base Parts: The filler cap is typically part of the overall arrangement of base components, ensuring that oil can be added without spillage or contamination. It is designed to fit securely within the base parts to maintain a sealed environment.

-

Oil Fill and Oil Pan: Directly connected to the oil pan, the filler cap allows for the easy addition of oil. It ensures that the oil level within the pan is maintained at an optimal level, which is essential for the lubrication of moving parts.

-

Breather and Breather Arrangement: The filler cap often incorporates a breather function, allowing air to escape from the crankcase as oil is added. This prevents pressure build-up, which could lead to oil leaks or other issues.

-

Cover and Cylinder Block Cover: Positioned on the cover of the cylinder block, the filler cap provides a convenient access point for oil addition while protecting the internal components from debris and contaminants.

-

Hand Hole and Oil Gauge: Many designs include a hand hole for easy access. Additionally, the filler cap may house an oil gauge or dipstick, allowing for quick checks of the oil level without removing the cap entirely.

-

Dipstick and Oil Fill Arrangement: The filler cap often includes a dipstick channel, enabling mechanics to assess the oil level accurately. This arrangement ensures that the engine is neither overfilled nor underfilled.

-

Valve Cover and Valve Cover Sub-option: On engines where the filler cap is integrated into the valve cover, it serves a dual purpose. It allows for oil addition while also providing a sealed cover for the valve components, preventing oil leaks and contamination.

-

Fill & Breather and EBM-Cover Cylinder Block: In systems where the filler cap doubles as a breather, it plays a role in managing crankcase pressure. The EBM-cover cylinder block often features this integrated design to enhance efficiency and reliability.

-

Oil Filler and Oil Fill & HHC (Hand Hole Cover): The filler cap may include a hand hole cover, offering a secure yet accessible point for oil addition. This design is particularly useful in high-maintenance environments where frequent oil checks are necessary.

-

Dipstick and Oil Fill: The integration of the dipstick within the filler cap allows for convenient oil level checks, ensuring that the engine remains properly lubricated without the need for multiple access points.

-

Rocker Lever Top Level Assembly Front Cover: In complex engine designs, the filler cap may be part of the front cover assembly, providing a unified point for oil addition and pressure management.

-

Valve Covers & Filler: When integrated into valve covers, the filler cap ensures that the valve train components are adequately lubricated while maintaining a sealed environment to prevent oil loss.

In summary, Part 107981 Filler Cap is a versatile component that enhances the functionality of various engine systems by providing a secure, convenient, and efficient means of adding and managing oil levels.

Conclusion

The Cummins 107981 Filler Cap is a critical component in the engine management system of commercial trucks. By understanding its purpose, role, and maintenance requirements, engineers, mechanics, truck drivers, and fleet operators can ensure the continued performance and safety of their vehicles. With its commitment to quality and innovation, Cummins is a trusted name in the commercial truck industry, providing reliable parts that meet the needs of operators around the world.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Tom Denton and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Gus Wright. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.