This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

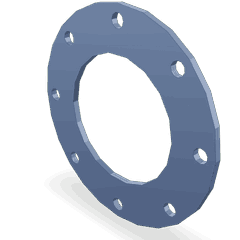

The Cummins Weld Flange 128129 is a specialized component designed for commercial truck applications. Cummins, a prominent name in the automotive and heavy-duty truck industry, manufactures this weld flange to meet the demanding requirements of truck systems. This part is integral to ensuring the efficient and reliable operation of various truck components.

Basic Concepts of Weld Flanges

Weld flanges are components used to connect pipes, valves, and other equipment in a system. They provide a means to seal and secure connections, allowing for easy disassembly and maintenance when needed. In a system, weld flanges facilitate the transfer of fluids or gases while withstanding pressure and temperature variations. They are commonly used in industries where robust and leak-proof connections are necessary 1.

Purpose of Weld Flange 128129 in Truck Operations

The Weld Flange 128129 is specifically designed to play a role in the operation of commercial trucks. It is applied in various truck systems where secure and durable connections are required. This includes fuel systems, hydraulic systems, and other critical components where the integrity of the connection is paramount to the system’s performance and safety 2.

Key Features of Weld Flange 128129

The Weld Flange 128129 boasts several key features that enhance its functionality. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design specifications of this flange include precise dimensions and tolerances to ensure a snug fit and reliable seal. Additionally, it may feature unique attributes such as reinforced edges or specialized coatings to further improve its performance in demanding environments 3.

Benefits of Using Weld Flange 128129

Utilizing the Weld Flange 128129 offers several advantages. Its robust construction contributes to the durability of the connection, reducing the likelihood of leaks or failures. The design of the flange also facilitates ease of installation, allowing for quick and secure connections. Furthermore, the performance enhancements provided by this flange can lead to improved efficiency and reliability in truck systems 4.

Installation Process

Proper installation of the Weld Flange 128129 is crucial to ensure its effectiveness. The installation process involves several steps, including preparing the connection surfaces, aligning the flange, and securing it in place using appropriate tools and equipment. Safety considerations, such as wearing protective gear and following manufacturer guidelines, should be observed during installation to prevent accidents and ensure a successful outcome.

Maintenance and Troubleshooting

Routine maintenance of the Weld Flange 128129 is recommended to ensure its longevity and optimal performance. This may include periodic inspections for signs of wear or damage, cleaning the connection surfaces, and tightening any loose components. Common issues that may arise with weld flanges include leaks or corrosion, which can often be addressed through proper maintenance practices or, if necessary, replacement of the flange.

Compatibility and Applications

The Weld Flange 128129 is typically applied within commercial truck systems where secure and durable connections are required. It is compatible with a range of components and systems, making it a versatile choice for various truck applications. When integrating this flange into a system, it is important to consider compatibility with other components to ensure seamless operation.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long-standing history in the automotive and heavy-duty truck industry. Known for producing high-quality components, Cummins offers a range of products that complement the Weld Flange 128129. Their commitment to innovation and excellence has established them as a trusted name in the industry, providing reliable solutions for commercial truck applications.

Weld Flange 128129 Compatibility with Cummins Engines

The Cummins Weld Flange part number 128129 is designed to fit a variety of Cummins engines, ensuring compatibility and reliability across different models. Here is an overview of its application:

Medium-Duty Engines

- K19: The K19 engine is a medium-duty diesel engine, and the Weld Flange 128129 is compatible with this model, providing a secure connection for exhaust and other systems.

- K38: Another medium-duty engine, the K38, also benefits from the use of the Weld Flange 128129, ensuring robust and leak-proof connections.

- K50: The K50 engine, known for its durability and performance, is another medium-duty engine that can utilize the Weld Flange 128129.

Heavy-Duty Engines

- M11 MECHANICAL: The M11 MECHANICAL engine, a heavy-duty model, is designed for high-performance applications. The Weld Flange 128129 fits seamlessly with this engine, providing essential support and durability.

- N14 MECHANICAL: The N14 MECHANICAL engine, another heavy-duty variant, is compatible with the Weld Flange 128129, ensuring reliable connections in demanding environments.

Industrial Engines

- NH/NT 855: The NH/NT 855 engine, used in industrial applications, is compatible with the Weld Flange 128129, providing a robust solution for exhaust and other critical connections.

- QSNT14 CM876 N102: This industrial engine model also benefits from the Weld Flange 128129, ensuring secure and leak-proof connections.

- QST30 CM552: The QST30 CM552 engine, another industrial powerhouse, is compatible with the Weld Flange 128129, offering reliable performance in various industrial settings.

Military Engines

- V28: The V28 engine, known for its use in military applications, is compatible with the Weld Flange 128129, ensuring durability and reliability in harsh conditions.

The Cummins Weld Flange 128129 is engineered to provide a secure and leak-proof connection across these diverse engine models, ensuring optimal performance and longevity.

Understanding the Role of Part 128129 Weld Flange in Engine Systems

Part 128129 Weld Flange is an essential component in the assembly and operation of various engine systems. Its primary function is to provide a secure and leak-proof connection between different parts of the exhaust system, ensuring efficient performance and durability.

Connection Points

The Weld Flange is utilized at multiple connection points within the engine system. It interfaces with the exhaust outlet, facilitating a robust link between the engine block and the exhaust system. This connection is vital for maintaining the integrity of the exhaust flow and preventing any potential leaks that could affect engine performance.

Exhaust Outlet and Elbow

At the exhaust outlet, the Weld Flange ensures a tight seal, which is necessary for the efficient expulsion of exhaust gases. It also plays a significant role in the exhaust elbow, where the direction of the exhaust flow changes. The flange’s design allows for a smooth transition, reducing the risk of turbulence and backpressure, which can negatively impact engine efficiency.

Turbocharger Connection

In turbocharged engines, the Weld Flange is instrumental in connecting the exhaust system to the turbocharger. This connection is particularly important as it must withstand high temperatures and pressures. The flange ensures that the exhaust gases are directed efficiently into the turbocharger, enhancing its performance and contributing to the overall power output of the engine.

Silencer Exhaust

The Weld Flange is also used in the connection to the silencer exhaust. This application is crucial for maintaining the structural integrity of the exhaust system while ensuring that the silencer functions effectively in reducing noise levels. The flange’s durable construction helps in withstanding the vibrations and thermal cycles experienced in this part of the system.

Exhaust Outlet Tube

Finally, the Weld Flange is employed in the connection to the exhaust outlet tube. This application ensures that the exhaust gases are channeled away from the engine compartment efficiently. The flange’s role here is to provide a secure and durable connection, which is essential for the long-term reliability of the exhaust system.

Conclusion

In summary, Part 128129 Weld Flange is a versatile component that plays a significant role in various connections within engine systems. Its applications range from the exhaust outlet to the turbocharger, ensuring efficient and reliable performance across different engine configurations.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.