141625

Idle Spring Plunger

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

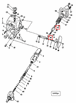

The Idle Spring Plunger (Part #141625) by Cummins is a component designed to contribute to the operation of commercial truck engines. It plays a role in maintaining engine performance by ensuring the engine operates smoothly at idle. This Cummins part is integral to the engine’s fuel system, where it helps regulate the idle speed, thereby supporting efficient engine operation under various conditions 1.

Function and Operation

The Idle Spring Plunger operates within the engine system by interacting with the fuel injection pump. Its primary role is to regulate the engine’s idle speed. When the engine is at idle, the plunger adjusts the fuel delivery to the engine, ensuring that the engine runs smoothly without stalling or surging. This interaction with the fuel injection system allows for precise control over the engine’s idle characteristics, contributing to overall engine efficiency and performance 2.

Key Features

The Idle Spring Plunger is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the high pressures and temperatures within the engine compartment. The plunger’s design includes a spring mechanism that provides the necessary force to adjust the fuel delivery accurately. Additionally, its construction from durable materials ensures longevity and reliability in demanding commercial truck applications.

Benefits

The Idle Spring Plunger offers several benefits that contribute to improved engine operation. By regulating the idle speed, it helps in achieving better engine efficiency, reducing the wear on engine components due to inconsistent idle speeds. Furthermore, it enhances the overall performance of the truck by ensuring that the engine operates within optimal parameters, leading to smoother idling and potentially lower fuel consumption 3.

Installation and Maintenance

Proper installation of the Idle Spring Plunger is crucial for its effective operation. It requires precise fitting within the fuel injection pump to ensure accurate fuel delivery. Maintenance of the plunger involves regular inspection for signs of wear or damage, and it should be replaced if any issues are detected to maintain engine performance. Additionally, keeping the fuel system clean and free from contaminants can help in prolonging the life of the plunger and other related components.

Troubleshooting Common Issues

Common issues with the Idle Spring Plunger may include leaks or malfunctions that affect engine idle. Troubleshooting these problems involves checking the plunger for signs of wear, ensuring it is correctly installed, and verifying that there are no obstructions or leaks in the fuel system. Addressing these issues promptly can help in maintaining the engine’s performance and preventing more significant problems down the line.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry, Cummins is known for its commitment to producing high-quality automotive components. The company’s history of innovation and excellence in engine technology underscores its position as a trusted provider of engine parts, including the Idle Spring Plunger.

Role of Part 141625 Idle Spring Plunger in Engine Systems

The Idle Spring Plunger, part 141625, is an integral component in the orchestration of engine systems, particularly in the regulation and maintenance of idle speed. This component interacts with several key systems to ensure optimal engine performance.

Interaction with Fuel Systems

In fuel-injected engines, the Idle Spring Plunger works in conjunction with the fuel pump and fuel calibration systems. It helps maintain a consistent idle speed by adjusting the air-fuel mixture. When the engine is at idle, the plunger modulates the airflow, which in turn affects the fuel delivery. This interaction is vital for the fuel pump to deliver the correct amount of fuel, as dictated by the fuel calibration settings.

Role in Calibration Processes

Calibration is a delicate process that ensures all engine components work in harmony. The Idle Spring Plunger is a key player in this process. It assists in fine-tuning the engine’s idle speed, which is particularly important during calibration procedures. Whether it’s a fuel calibration or a more general engine calibration, the plunger’s role is to provide the necessary adjustments to achieve the desired idle speed.

Contribution to Code-Based Systems

Modern engines often rely on code-based systems for operation, including fuel codes and pump codes. The Idle Spring Plunger interfaces with these systems to ensure that the engine operates within the parameters set by these codes. For instance, in systems utilizing Pump Code CPL 187, CPL 196, CPL 202, or CPL 22, the plunger’s adjustments are crucial for the engine to comply with these specific codes.

Functionality in Uncalibrated Systems

In uncalibrated or auto systems, the Idle Spring Plunger takes on an even more significant role. Without the precise settings of a calibrated system, the plunger must work harder to maintain a stable idle speed. It does this by constantly adjusting the air-fuel mixture to compensate for the lack of calibration. This is particularly noticeable in comparisons between uncalibrated and calibrated systems, where the plunger’s adjustments are more frequent and pronounced in the former.

Conclusion

In summary, the Idle Spring Plunger, part 141625, is a versatile component that plays a significant role in various engine systems. Its ability to adjust and modulate engine parameters makes it a key component in ensuring smooth and efficient engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.