This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

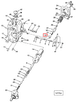

The Idle Spring Plunger (Part #141629) by Cummins is a component designed to enhance the operation of commercial trucks. Its purpose is to regulate fuel delivery during idle conditions, ensuring the engine operates smoothly and efficiently. This Cummins part is significant in maintaining the overall performance and reliability of the truck’s engine.

Function and Operation

The Idle Spring Plunger operates within the fuel injection system of a truck engine. It plays a role in maintaining proper fuel delivery during idle conditions by adjusting the fuel injection timing and quantity. When the engine is idling, the plunger modulates the fuel flow to the injectors, ensuring that the engine receives the correct amount of fuel for stable operation. This regulation helps in maintaining engine RPM within the desired range and contributes to a smoother idle 2.

Key Features

The Idle Spring Plunger is characterized by its precise design and the materials used in its construction. It is typically made from high-quality steel or a durable polymer, ensuring resistance to wear and corrosion. The plunger features a spring mechanism that allows it to respond accurately to changes in engine load and RPM. This design enhances its performance and durability, making it suitable for the demanding conditions of commercial truck operation 1.

Benefits

The Idle Spring Plunger offers several advantages. It contributes to improved fuel efficiency by ensuring that the engine operates with optimal fuel delivery during idle. This can lead to reduced fuel consumption and lower operating costs. Additionally, proper fuel regulation during idle can result in reduced emissions, as the engine burns fuel more cleanly. The plunger also enhances engine performance during idle operation, providing a smoother and more stable idle, which is particularly important for applications where the engine spends a significant amount of time idling, such as in heavy-duty trucks used for logistics and transportation 2.

Installation and Compatibility

Proper installation of the Idle Spring Plunger is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the fuel injection system. Compatibility with various Cummins engine models is an important consideration, and it is advisable to consult the specific compatibility information provided by Cummins to ensure the part is suitable for the engine in question 2.

Maintenance and Troubleshooting

To ensure optimal performance and longevity of the Idle Spring Plunger, regular maintenance is recommended. This includes checking for any signs of wear or damage and ensuring that the spring mechanism operates smoothly. Common issues that may arise include irregular idle or difficulty in maintaining engine RPM during idle. Troubleshooting steps may involve inspecting the plunger for debris or obstructions, ensuring the spring is functioning correctly, and verifying that the fuel injection system is clean and free from contaminants 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product offerings include engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency. Cummins is known for its commitment to customer satisfaction and its focus on developing solutions that meet the evolving needs of the transportation and power generation industries 2.

Idle Spring Plunger Compatibility with Cummins Engines

The Idle Spring Plunger part number 141629, manufactured by Cummins, is designed to fit a variety of engines, ensuring smooth and efficient operation. Here is a detailed look at its compatibility across different engine models:

K-Series Engines

- K19: This engine benefits from the Idle Spring Plunger, which helps maintain the correct idle speed by regulating the spring pressure.

- K38: The Idle Spring Plunger is crucial for the K38 engine, providing the necessary balance to the idle mechanism.

- K50: The K50 engine also utilizes the Idle Spring Plunger to ensure that the engine idles smoothly without fluctuations.

L-Series Engines

- L10 MECHANICAL: The Idle Spring Plunger is integral to the L10 MECHANICAL engine, aiding in the precise control of idle speed.

M-Series Engines

- M11 CELECT PLUS: The Idle Spring Plunger is compatible with the M11 CELECT PLUS engine, enhancing the engine’s idle performance.

- M11 MECHANICAL: This engine also relies on the Idle Spring Plunger for maintaining stable idle conditions.

N-Series Engines

- N14 MECHANICAL: The Idle Spring Plunger is a key component for the N14 MECHANICAL engine, ensuring that the engine idles at the correct speed.

NH/NT Series Engines

- NH/NT 855: The Idle Spring Plunger is designed to fit the NH/NT 855 engines, contributing to the engine’s smooth idle operation.

Each of these engines benefits from the Idle Spring Plunger in maintaining optimal idle performance, ensuring that the engine operates efficiently and reliably 2.

Role of Part 141629 Idle Spring Plunger in Engine Systems

The Idle Spring Plunger, part 141629, is an integral component in maintaining the delicate balance of engine systems, particularly in relation to fuel management and calibration.

Interaction with Fuel Pump and Calibration Systems

In engine systems, the Idle Spring Plunger works in conjunction with the fuel pump to regulate the fuel supply. The fuel pump, responsible for delivering fuel from the tank to the engine, must operate within precise parameters to ensure optimal performance and efficiency. The Idle Spring Plunger aids in this by helping to maintain consistent fuel pressure, which is vital for the engine’s idle stability 2.

Calibration and Code Integration

Calibration is a key aspect of engine performance, and the Idle Spring Plunger plays a role here as well. It interacts with various calibration codes (such as CPL 101, CPL 11, CPL 111, etc.) that are programmed into the engine’s control unit. These codes dictate how the fuel pump operates under different conditions. The plunger’s function is to ensure that the physical aspects of fuel delivery align with these digital calibrations, thus maintaining the engine’s intended performance characteristics 2.

Specific Calibration Codes and Their Relation

-

Pump Code CPL 101 and CPL 11: These codes often relate to basic fuel pump settings. The Idle Spring Plunger ensures that the mechanical aspects of the fuel system correspond with these settings, particularly during idle conditions.

-

Pump Code CPL 181 and CPL 187: These are more advanced calibrations, typically used in high-performance or specialized engines. The plunger’s role here is to fine-tune the fuel delivery to match these advanced settings.

-

Pump Code CPL 207 and CPL 217: Often found in engines requiring precise fuel control for emissions compliance, the plunger assists in maintaining the exact fuel pressure needed to meet these standards.

Fuel Pump Calibration and Code Fuel Dynamics

The relationship between the Idle Spring Plunger and fuel pump calibration (like EBM: Calibration or F. Pump) is dynamic. As the engine’s demands change – whether it’s idling, accelerating, or decelerating – the plunger adjusts to ensure that the fuel pump’s output aligns with the calibration codes. This is particularly important in codes like Pump Code CPL-0009 or Pump Code CPL-10, where precise fuel delivery is essential for engine efficiency and performance 2.

Specialized Calibrations

In systems with specialized calibrations like Pump Code CPL 66 or Pump Code CPL205, the Idle Spring Plunger’s role becomes even more significant. These calibrations are often tailored for specific engine characteristics or performance requirements, and the plunger’s ability to adapt and maintain consistency in fuel delivery is key to achieving the desired engine behavior 2.

Conclusion

In summary, the Idle Spring Plunger, part 141629, is a vital component in the intricate dance of engine calibration and fuel management. Its interaction with various fuel pump calibrations and codes ensures that the engine operates smoothly and efficiently across a range of conditions. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall performance and reliability of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.