This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 146299 Plain Tube Coupling is a component manufactured by Cummins, a well-established name in the commercial truck industry. This coupling is significant in commercial truck systems due to its role in ensuring the efficient transfer of fluids, which is vital for the operation of various truck systems 1.

Basic Concepts of Plain Tube Couplings

Plain tube couplings are devices used to connect two tubes in fluid systems. They facilitate the transfer of fluids such as fuel, coolant, and hydraulic fluid without the need for additional sealing elements. These couplings operate by compressing the tubes together, creating a seal that allows for the passage of fluids while withstanding pressure and vibration inherent in a truck’s infrastructure 2.

Purpose of the 146299 Plain Tube Coupling

This Cummins part is designed to connect specific systems within a truck, handling the transfer of fluids that are crucial for the truck’s operation. It plays a role in maintaining the integrity of fluid lines by providing a secure and leak-proof connection. The coupling is integral to systems that require reliable fluid transfer, such as fuel lines and hydraulic systems.

Key Features

The 146299 boasts several key features that enhance its functionality. It is constructed from durable materials that can withstand the harsh conditions present in commercial truck environments. The design includes precision-machined components that ensure a tight fit and reliable seal. Additionally, the coupling may feature unique attributes such as corrosion-resistant coatings or enhanced grip mechanisms to further improve performance 3.

Benefits of Using the 146299 Plain Tube Coupling

Utilizing this part offers several advantages. Its robust construction contributes to durability, ensuring long-term reliability in demanding applications. The design of the coupling allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, the coupling’s efficiency in fluid transfer helps maintain system performance and contributes to the overall reliability of the truck’s fluid systems.

Installation Process

Installing the 146299 requires attention to detail and adherence to safety protocols. The process involves preparing the tubes for connection, aligning them within the coupling, and then compressing the coupling to create a seal. Tools such as torque wrenches may be required to ensure proper tightening. Safety precautions include wearing appropriate personal protective equipment and ensuring that the system is depressurized before beginning work.

Maintenance Tips

To ensure the longevity and optimal performance of the 146299, regular maintenance is recommended. This includes inspecting the coupling for signs of wear or damage, cleaning the coupling and surrounding areas to prevent contamination, and verifying that the connection remains secure. Adhering to manufacturer-recommended inspection intervals will help identify potential issues before they lead to system failures.

Troubleshooting Common Issues

Common problems associated with plain tube couplings, such as leaks or corrosion, can often be addressed through maintenance actions. If a leak is detected, the coupling should be inspected for proper installation and the tubes checked for damage. Corrosion can be mitigated by ensuring that the coupling is made from or coated with corrosion-resistant materials and by keeping the area clean and dry.

Compatibility and Applications

The 146299 is designed for use in specific types of trucks and systems. It is commonly applied in industries where reliable fluid transfer is paramount, such as in the transportation of goods and materials. The coupling’s design and construction make it suitable for a variety of applications within the commercial truck sector.

Safety Considerations

When working with the 146299, it is important to observe safety practices. This includes handling fluids with care to avoid spills and contamination, as well as following operational safety measures to prevent accidents. Proper training and the use of safety equipment are recommended when performing maintenance or repairs on systems incorporating this coupling.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems that contribute to the efficiency and reliability of commercial vehicles.

Role of Part 146299 Plain Tube Coupling in Engine Systems

The Part 146299 Plain Tube Coupling is integral to the seamless operation of various engine components. Its primary function is to ensure secure and leak-free connections between different tubes and fittings within the engine system.

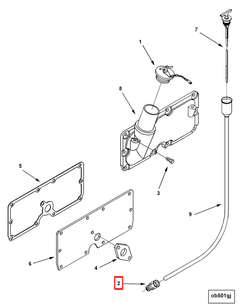

Integration with the Arrangement

In the engine arrangement, the Plain Tube Coupling is used to connect various tubes that facilitate the flow of fluids and gases. This ensures that all components are properly aligned and that there are no leaks in the system. The coupling allows for easy disassembly and reassembly, which is essential during maintenance or repairs.

Connection to the Oil Fill System

The oil fill system relies on the Plain Tube Coupling to connect the oil fill tube to the engine block. This connection is vital for the proper introduction of oil into the engine. The coupling ensures that oil is delivered efficiently without any spills or leaks, maintaining the integrity of the oil fill process.

Role in the Oil Gauge Tube

For the oil gauge tube, the Plain Tube Coupling is used to connect the gauge to the engine’s oil system. This connection allows for accurate measurement of oil levels within the engine. The coupling ensures a tight seal, preventing any oil from escaping and providing reliable readings on the gauge.

Application in the Reverse Gear System

In the reverse gear system, the Plain Tube Coupling is employed to connect hydraulic lines or other fluid pathways that are essential for the operation of the reverse gear mechanism. This ensures that the fluid flow is consistent and that the reverse gear engages smoothly without any interruptions. The coupling’s durability and reliability are key to the sustained performance of the reverse gear system.

Conclusion

The 146299 Plain Tube Coupling is a vital component in the operation of commercial truck systems, ensuring efficient and reliable fluid transfer across various applications. Its robust design, ease of installation, and maintenance-friendly features make it a preferred choice for professionals in the industry. Regular maintenance and adherence to safety practices are essential to maximize the performance and longevity of this coupling.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.