Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 149134 Lockplate is a component designed for use in commercial trucks. It serves a specific function within the engine or transmission system, contributing to the overall reliability and performance of the vehicle. Understanding its purpose and significance is important for maintaining the efficiency and safety of truck operations.

Basic Concepts of Lockplates

A lockplate, in general, is a thin metal plate used in mechanical systems to secure components in place. It operates by preventing movement or loosening of parts that could otherwise lead to mechanical failure. In the context of a truck’s engine or transmission, lockplates play a role in ensuring that critical components remain fixed and aligned, thereby supporting the smooth operation of the vehicle 1.

Purpose of the 149134 Lockplate

The Cummins 149134 Lockplate is specifically designed to secure components within the truck’s engine or transmission system. Its function is to maintain the alignment and stability of parts that are subject to vibration and movement during operation. By doing so, it helps in preserving the integrity of the engine or transmission, contributing to the truck’s overall performance and longevity.

Key Features

The 149134 Lockplate is characterized by its precise design and material composition, which typically includes high-strength steel. This material choice enhances its durability and resistance to wear. The lockplate’s design allows it to fit securely around the components it is meant to stabilize, ensuring a tight and reliable hold.

Benefits

The use of the 149134 Lockplate offers several advantages. It contributes to improved safety by reducing the risk of component failure due to loosening. Additionally, it enhances the performance of the truck by ensuring that engine or transmission parts operate within their designed parameters. The lockplate also supports increased longevity of the truck’s components by minimizing wear and tear associated with movement and vibration 2.

Installation Process

Installing the Cummins 149134 Lockplate requires careful attention to detail. The process involves securing the lockplate around the designated components using appropriate tools. It is important to follow manufacturer guidelines to ensure proper installation. Safety precautions, such as wearing protective gear and ensuring the engine is off, should be observed during the installation process.

Troubleshooting Common Issues

Common issues with the 149134 Lockplate may include improper installation leading to component misalignment or failure to secure parts adequately. Diagnostic steps involve inspecting the lockplate for correct placement and ensuring it is firmly in position. Solutions may require reinstallation or replacement of the lockplate if damage is detected.

Maintenance Tips

Regular maintenance of the 149134 Lockplate is important for ensuring its optimal functioning. This includes periodic inspection for signs of wear or damage and cleaning to remove any debris that could affect its performance. Adhering to recommended inspection intervals and maintenance procedures will help in preserving the lockplate’s effectiveness and the overall health of the truck’s engine or transmission system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 3.

Understanding the Role of Part 149134 Lockplate in Engine Systems

In the intricate world of engine systems, the integration of various components is essential for optimal performance and reliability. Among these components, the part 149134 Lockplate plays a significant role in ensuring the seamless operation of several key elements.

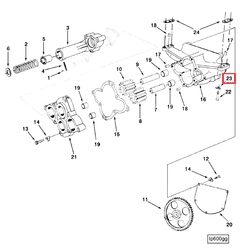

Integration with Base Components

The Lockplate is designed to work in conjunction with base parts, which form the foundational structure of the engine. By securing these base components, the Lockplate helps maintain the structural integrity and alignment necessary for efficient engine function. This is particularly important in high-stress environments where vibrations and thermal expansion can lead to component misalignment.

Role in Lubricating Systems

In systems involving lubricating oil, the Lockplate ensures that the lubricating oil mounting pump remains securely in place. This is vital for maintaining consistent oil flow and pressure, which are essential for reducing friction and wear on moving parts. The Lockplate’s secure fit prevents any potential leaks or disruptions in the oil supply, thereby enhancing the longevity and performance of the engine.

Contribution to EBM-Pump Efficiency

The Lockplate also plays a part in the efficiency of the EBM-pump (Electromagnetic Brake Motor pump). By ensuring that the pump components are held firmly in place, the Lockplate contributes to the pump’s ability to deliver precise and reliable fluid movement. This is particularly important in applications where the pump is responsible for critical functions such as cooling or hydraulic actuation.

Support in LP Conversion Kits

In LP (Liquid Propane) conversion kits, the Lockplate is instrumental in maintaining the integrity of the conversion process. It ensures that all converted components, including the base parts and pump systems, are securely fastened. This is essential for safe and efficient operation, as any misalignment or loose fitting can lead to hazardous conditions or reduced performance.

Enhancing Bulk Parts List Reliability

When considering the bulk parts list for engine maintenance or replacement, the inclusion of the Lockplate is a testament to its reliability and importance. It ensures that all listed parts, from the base to the pump, are securely integrated into the engine system. This not only facilitates easier assembly and disassembly but also contributes to the overall robustness of the engine.

Conclusion

The part 149134 Lockplate, though seemingly a small component, plays a substantial role in the reliable operation of various engine systems. Its ability to secure and align critical components ensures that the engine performs efficiently and reliably, making it an indispensable part of the engine’s design.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.