This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Plug, Drive - Dipstick Hole (Part #152593) manufactured by Cummins is a component designed for use in commercial truck engines. It plays a role in maintaining engine performance and integrity by facilitating the monitoring of oil levels, which is vital for the proper functioning of the engine’s lubrication system 1.

Purpose and Function

The primary purpose of this Cummins part is to allow for the checking of oil levels within a truck engine. This component is integral to the lubrication system, ensuring that the engine operates within the optimal oil level range. By providing a secure point of access for the dipstick, it enables regular monitoring and maintenance of the engine’s oil levels, which is crucial for the engine’s longevity and efficiency 2.

Key Features

The Plug, Drive - Dipstick Hole is characterized by its robust design and material composition, which are tailored to withstand the demanding conditions of heavy-duty truck engines. It is constructed from high-quality materials that offer durability and resistance to wear and corrosion. Its design ensures a tight seal around the dipstick, preventing oil leaks and maintaining the integrity of the engine’s lubrication system.

Benefits

Utilizing the Plug, Drive - Dipstick Hole in commercial truck engines offers several benefits. It contributes to improved engine maintenance by providing a reliable method for checking oil levels. This leads to enhanced lubrication system efficiency, as maintaining the correct oil level is key to reducing friction and wear on engine components. Additionally, proper maintenance of oil levels can contribute to the overall longevity of the engine.

Installation and Usage

For optimal performance and safety, the Plug, Drive - Dipstick Hole should be installed according to manufacturer guidelines. This involves ensuring a proper fit within the engine block and securing it in place to create a seal around the dipstick. Following these guidelines helps maintain the integrity of the engine’s lubrication system and ensures accurate oil level readings.

Troubleshooting and Maintenance

Common issues with the Plug, Drive - Dipstick Hole may include leaks or difficulty in inserting the dipstick. Troubleshooting steps may involve inspecting the plug for damage or wear and ensuring it is correctly installed. Regular maintenance, including periodic inspection and replacement as necessary, can help ensure the longevity and proper functioning of this component.

Safety Considerations

When handling and installing the Plug, Drive - Dipstick Hole, it is important to observe safety guidelines and precautions. This includes ensuring the engine is cool before attempting installation or removal and following manufacturer recommendations to avoid accidents. Proper handling and installation are key to ensuring safe operation and maintaining the integrity of the engine’s lubrication system.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation in engine component manufacturing. With a broad product range and a reputation for reliability, Cummins continues to be a trusted name in the industry, providing components that contribute to the efficiency and longevity of commercial truck engines.

Plug, Drive - Dipstick Hole Compatibility with Cummins Engines

The Plug, Drive - Dipstick Hole part number 152593, manufactured by Cummins, is designed to fit seamlessly into specific engine models. This part is crucial for maintaining the integrity of the engine’s oil system by ensuring that the dipstick hole is properly sealed and functional.

N14 MECHANICAL

The N14 MECHANICAL engine benefits from the precise fit of the 152593 plug, ensuring that the oil level can be accurately checked without any leaks. This part is engineered to withstand the operational stresses of the N14 MECHANICAL engine, providing a reliable seal that is essential for maintaining optimal engine performance.

NH/NT 855

Similarly, the NH/NT 855 engine is compatible with the 152593 plug. This part fits into the engine’s design to ensure that the dipstick hole remains sealed, preventing any oil from leaking out and allowing for accurate oil level monitoring. The compatibility of this plug with the NH/NT 855 engine ensures that the engine’s oil system operates efficiently.

QSNT14 CM876 N102

The QSNT14 CM876 N102 engine also integrates the 152593 plug effectively. This part is designed to fit the specific contours of the engine, ensuring a tight seal around the dipstick hole. The compatibility of this plug with the QSNT14 CM876 N102 engine is critical for maintaining the engine’s oil level and preventing any potential oil leaks.

By ensuring that the 152593 plug fits correctly into these engines, Cummins maintains the reliability and performance of the oil system, which is essential for the overall health of the engine.

Role of Part 152593 Plug, Drive - Dipstick Hole in Engine Systems

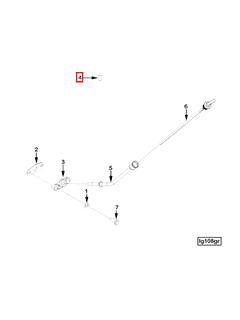

The Part 152593 Plug, Drive - Dipstick Hole is an integral component in the arrangement of various engine systems, ensuring the proper functioning and maintenance of the engine.

In the oil fill system, this part allows for the secure insertion of the dipstick, which is essential for accurate oil level readings. It interfaces directly with the dipstick and tube arrangement, providing a sealed environment that prevents oil leakage and contamination.

The dipstick arrangement relies on the Plug, Drive - Dipstick Hole to maintain the integrity of the oil level measurement system. This ensures that the dipstick can be properly inserted and removed without any issues, facilitating regular oil level checks.

In conjunction with the Engine Bay Module (EBM) cover, the Plug, Drive - Dipstick Hole helps in maintaining a clean and organized engine compartment. It ensures that the dipstick mechanism is protected from external debris and contaminants.

The oil pan system benefits from this part by ensuring that the dipstick can accurately gauge the oil level within the pan. This is vital for maintaining optimal oil levels, which in turn supports the lubrication and cooling of engine components.

The gauge system, specifically the oil level gauge, depends on the accurate readings provided by the dipstick. The Plug, Drive - Dipstick Hole ensures that the dipstick is correctly positioned, allowing the gauge to display the true oil level.

In the context of the oil system, this part plays a role in the overall maintenance routine. It ensures that the oil filler cap can be securely fastened, preventing any oil from escaping during operation.

The hand hole cover and hand hole cover & fitting also interact with the Plug, Drive - Dipstick Hole. It ensures that access to the dipstick is straightforward, allowing for easy removal and reinsertion during oil checks.

Finally, the oil gauge system relies on the accurate data provided by the dipstick, which is securely held in place by the Plug, Drive - Dipstick Hole. This ensures that the gauge readings are reliable, aiding in the monitoring of oil levels and the overall health of the engine.

Conclusion

The Plug, Drive - Dipstick Hole (Part #152593) by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its role in facilitating accurate oil level checks, ensuring the integrity of the lubrication system, and contributing to the overall efficiency and longevity of the engine cannot be overstated. Proper installation, maintenance, and understanding of its compatibility with specific engine models are essential for maximizing its benefits and ensuring the optimal performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.