This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

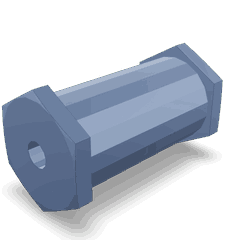

The Cummins 178079 Check Valve is a specialized component designed for use in commercial truck systems. Its purpose is to regulate the flow of fluids within the system, ensuring that fluid moves in the intended direction and preventing backflow. This valve plays a significant role in maintaining the efficiency and reliability of various systems in commercial trucks.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a movable element, such as a flap or a ball, that opens to allow fluid flow in one direction and closes to prevent flow in the opposite direction. Check valves are commonly used in fluid systems to prevent backflow, which can cause damage to pumps, contamination of fluids, and other operational issues 1.

Function and Role in Truck Systems

The Cummins 178079 Check Valve is specifically designed to support the operation of commercial trucks. It is typically placed in systems where the prevention of backflow is crucial, such as in fuel, hydraulic, and lubrication systems. By ensuring that fluid flows in the correct direction, this valve helps maintain system pressure, protect sensitive components, and enhance overall system performance. Its placement within the system is strategic, often near pumps or other critical components to maximize its effectiveness.

Key Features

The Cummins 178079 Check Valve is characterized by several key features that enhance its performance and durability. Its design includes a robust body made from high-quality materials resistant to corrosion and wear. The valve incorporates a precision-machined seat and a durable disc or ball that ensures a tight seal when closed. Additionally, it features a simple yet effective mechanism for opening and closing, which minimizes the risk of malfunction. These design elements contribute to the valve’s reliability and longevity in demanding commercial truck applications.

Benefits

The use of the Cummins 178079 Check Valve in commercial truck systems offers several benefits. It improves system efficiency by ensuring that fluid flows in the intended direction, reducing the risk of backflow and associated issues. This valve also contributes to the prevention of contamination within the system, protecting sensitive components from damage. Furthermore, by maintaining system pressure and flow integrity, it enhances the overall reliability of the truck’s systems, leading to reduced maintenance needs and improved operational performance 2.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 178079 Check Valve include leakage, difficulty in opening or closing, and reduced flow efficiency. Troubleshooting these issues often involves checking for obstructions, inspecting the seal for wear or damage, and ensuring that the valve is correctly installed and aligned within the system. Regular maintenance practices, such as cleaning the valve and inspecting its components for signs of wear, can help ensure its longevity and optimal performance. It is also important to follow the manufacturer’s guidelines for maintenance intervals and procedures to maximize the valve’s effectiveness.

Cummins Check Valve 178079 Compatibility

The Cummins Check Valve part number 178079 is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal performance and reliability. Below is a detailed breakdown of the engines with which this check valve is compatible:

Cummins K Series Engines

- K19

- K38

- K50

These K series engines are known for their robust design and are commonly used in various industrial and agricultural applications. The check valve 178079 is engineered to integrate smoothly with these engines, providing efficient flow control and preventing backflow.

Cummins L Series Engines

- L10 MECHANICAL

The L10 MECHANICAL engine is a reliable choice for heavy-duty applications. The check valve 178079 is specifically designed to fit this engine, ensuring that it operates smoothly and efficiently.

Cummins N Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine is another robust option, often used in demanding environments. The check valve 178079 is compatible with this engine, providing the necessary flow control and preventing backflow.

Cummins NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine is a versatile option used in a variety of applications. The check valve 178079 is designed to fit this engine, ensuring that it operates efficiently and reliably.

Cummins QSN Series Engines

- QSNT14 CM876 N102

The QSNT14 CM876 N102 engine is a high-performance option often used in demanding industrial applications. The check valve 178079 is compatible with this engine, providing the necessary flow control and preventing backflow.

Cummins V Series Engines

- V28

- V903

The V28 and V903 engines are known for their power and reliability. The check valve 178079 is designed to fit these engines, ensuring that they operate smoothly and efficiently.

By ensuring compatibility with these engines, the Cummins Check Valve 178079 helps maintain the performance and longevity of the engines, providing a reliable solution for flow control and backflow prevention.

Role of Part 178079 Check Valve in Engine Systems

The part 178079 Check Valve is an integral component in various engine systems, ensuring the proper flow and regulation of fluids. Its application spans across multiple subsystems, enhancing the overall efficiency and reliability of the engine.

Fuel System Integration

In the fuel system, the Check Valve is positioned to prevent backflow, ensuring that fuel moves in the intended direction. It is commonly mounted using the Fuel Check Valve Mounting hardware, which secures it in place within the Fuel Tubing. This setup is vital for maintaining consistent fuel pressure and preventing contamination.

The Check Valve also interfaces with the Fuel Bypass Tube Mounting and Fuel Bypass Hose, allowing excess fuel to be redirected when necessary. This integration helps in maintaining optimal fuel flow rates and protecting sensitive components from over-pressurization.

Oil System Functionality

Within the oil system, the Check Valve plays a significant role in regulating oil flow. It is often found in conjunction with the Oil Control Valve Plumbing and Oil Transfer LB Connection. These connections ensure that oil is distributed efficiently to various engine components, such as the Right Bank Oil Supply Connection.

The Check Valve also works with the Drain Assist System (QV60) to manage oil drainage effectively. By preventing backflow, it ensures that oil is correctly channeled away from critical areas, reducing the risk of oil contamination and system malfunctions.

Hydro-Mechanical Step System

In the hydro-mechanical step system, the Check Valve is essential for maintaining pressure integrity. It is typically mounted using the Step Mounting Plumbing and connected to the Step Valve Plumbing. This configuration ensures that hydraulic fluid flows in the correct direction, supporting the precise operation of mechanical steps and actuators.

Accessories and Mounting Components

The Check Valve is often accompanied by various mounting components such as the Fuel Drain Tube Mounting and Fuel Bypass Mounting Tube. These accessories facilitate secure installation and integration within the engine’s complex network of tubes and connections.

Additionally, the Check Valve may be part of a Dual Check Fuel Tubing system, where it works in tandem with other valves to provide redundant protection against backflow. This setup is particularly important in high-stress environments where reliability is paramount.

Overall System Enhancement

By preventing backflow and ensuring unidirectional fluid movement, the Check Valve contributes to the stability and efficiency of the engine’s fluid systems. Its integration with components like the Fuel System SPO and Connecting Rod and Piston assemblies underscores its importance in maintaining optimal engine performance 3.

Conclusion

The Cummins 178079 Check Valve is a critical component in commercial truck systems, ensuring the proper flow and regulation of fluids across various subsystems. Its robust design, compatibility with multiple Cummins engines, and integration within fuel, oil, and hydro-mechanical systems highlight its importance in maintaining engine efficiency and reliability. Regular maintenance and adherence to manufacturer guidelines are essential for maximizing the valve’s performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.