The Offset Woodruff Key, identified by Part #200715, is a specialized component utilized in various mechanical systems, with a significant application in Cummins engines. This key is integral to the mechanical integrity and operational efficiency of these engines, ensuring precise alignment and secure fitting of critical components.

Basic Concepts

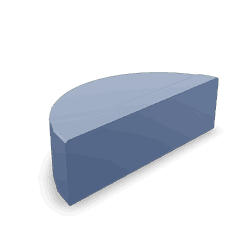

An Offset Woodruff Key is a type of key used in machinery to prevent relative rotation between a shaft and the components mounted on it. Its design features a semi-circular cross-section, which fits into a matching groove cut into the shaft. This key operates by locking the component in place, allowing for torque transmission without slippage. In the context of an engine, it plays a role in maintaining the alignment and secure attachment of components such as gears and pulleys to the crankshaft 1.

Purpose of the Offset Woodruff Key

In the operation of a truck, particularly those equipped with Cummins engines, the Offset Woodruff Key serves to ensure proper alignment and prevent rotational movement between the crankshaft and other components. This alignment is crucial for the efficient transfer of power and the smooth operation of the engine. By securing components in place, the key contributes to the stability and reliability of the engine’s performance 2.

Key Features

The Offset Woodruff Key is characterized by several distinctive features that make it suitable for heavy-duty applications. It is typically made from high-strength materials to withstand the rigors of engine operation. Its dimensions are precisely engineered to fit specific grooves in shafts, ensuring a secure and stable connection. The design of the key, with its offset feature, allows for additional clearance in certain applications, enhancing its functionality in complex engine designs 3.

Benefits

The use of an Offset Woodruff Key offers several advantages, including improved engine performance, durability, and reliability. By ensuring components are securely aligned and attached, the key contributes to the efficient operation of the engine. Its robust construction and precise design enhance the overall efficiency and longevity of the truck, making it a valuable component in heavy-duty engine systems 4.

Installation Process

Proper installation of the Offset Woodruff Key is critical for its effective function. The process involves carefully aligning the key with the groove in the shaft and ensuring it is securely fitted. Best practices include verifying the correct orientation of the key and using appropriate tools to avoid damage. Common pitfalls to avoid include improper alignment and insufficient securing of the key, which can lead to component slippage and engine inefficiency 5.

Troubleshooting and Maintenance

Identifying common issues related to the Offset Woodruff Key, such as wear and tear or misalignment, is important for maintaining engine performance. Routine maintenance practices, including regular inspection and replacement of worn keys, can ensure optimal performance and longevity of the part. Attention to these details can prevent more significant engine problems and contribute to the overall reliability of the truck 6.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation in engine manufacturing. With a rich history of producing reliable and efficient engines, Cummins has established a reputation for excellence. The company’s dedication to advancing engine technology and maintaining high standards of manufacturing ensures that its components, including the Offset Woodruff Key, meet the demanding requirements of heavy-duty applications 7.

Role of Part 200715 Offset Woodruff Key in Engine Systems

This Cummins part is integral to the secure and precise operation of various engine components. Its primary function is to prevent rotational movement between the shaft and the hub, ensuring that components remain aligned and operate efficiently.

In the context of a Cylinder Long Block, the Offset Woodruff Key is used to secure the V6 Camshaft Assembly or V8 Camshaft Assembly to the camshaft sprocket. This ensures that the camshaft rotates in perfect synchronization with the crankshaft, which is essential for the accurate timing of valve operations. Without this key, the camshaft could shift, leading to misaligned valve timing and potential engine damage.

Similarly, in a Cylinder Short Block, this part plays a role in securing other rotating components, such as the crankshaft sprocket, to the crankshaft. This is vital for maintaining the integrity of the timing chain or belt system, which coordinates the movement of the crankshaft and camshaft.

For Performance Parts, the Offset Woodruff Key is often used in high-performance camshaft assemblies where precision and reliability are paramount. These assemblies demand components that can withstand higher stresses and maintain exact alignment under extreme conditions. The key ensures that even under high RPMs, the camshaft remains securely in place, contributing to the overall performance and durability of the engine.

Conclusion

In summary, the Offset Woodruff Key (part 200715) is a small yet significant component that ensures the reliable operation of various engine systems by maintaining the precise alignment of rotating parts. Its robust design and precise engineering make it a critical component in the efficient and durable operation of Cummins engines.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4021942, QSM11 Industrial.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4021942, QSM11 Industrial.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4021942, QSM11 Industrial.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4021942, QSM11 Industrial.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.