This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

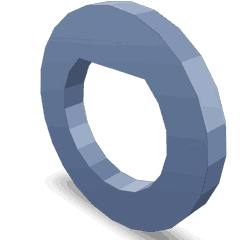

The Cummins 201745 Thrust Ring is a component designed for use in heavy-duty truck engines. It serves a specific function within the engine’s mechanical system, contributing to the overall efficiency and reliability of the engine. Understanding its purpose and significance is key to maintaining and optimizing engine performance.

Basic Concepts of Thrust Rings

Thrust rings are mechanical components used in various systems to manage axial loads. In an engine, they help control the movement of rotating parts along the axis of rotation. By providing a stable surface for these parts to press against, thrust rings play a role in maintaining the alignment and integrity of the engine’s components under operational stress 1.

Purpose of the 201745 Thrust Ring

The Cummins 201745 Thrust Ring is specifically engineered to manage axial loads within a truck engine. It operates by supporting the axial movement of certain engine components, ensuring they remain properly aligned and function efficiently. This component is integral to the engine’s ability to handle the stresses of heavy-duty operations, contributing to smooth and reliable performance 2.

Key Features

The 201745 Thrust Ring is characterized by its robust material composition and precise design. Crafted from high-quality materials, it is built to withstand the demanding conditions of heavy-duty truck engines. Its design includes features that enhance its durability and performance, such as a smooth surface to reduce friction and wear, and a structure that ensures it can effectively manage axial loads.

Benefits of Using the 201745 Thrust Ring

Incorporating the 201745 Thrust Ring into a truck engine can lead to several advantages. These include improved engine durability due to its ability to manage axial loads effectively, enhanced performance as a result of reduced friction and wear on engine components, and increased reliability in heavy-duty applications. These benefits contribute to the overall efficiency and longevity of the engine 3.

Installation Considerations

Proper installation of the 201745 Thrust Ring is vital for ensuring optimal performance and longevity. Guidelines for installation include ensuring the engine is clean and free of debris, correctly aligning the thrust ring with other components, and using the appropriate tools to secure it in place. Following these best practices helps maintain the integrity of the engine’s mechanical system.

Troubleshooting Common Issues

Thrust rings, including the 201745 model, may encounter issues such as wear, misalignment, or damage. Identifying these problems early is important for maintaining engine efficiency. Diagnostic methods may involve visual inspections, performance tests, and analysis of engine operation. Potential solutions range from realigning or replacing the thrust ring to addressing underlying issues within the engine’s mechanical system.

Maintenance Tips

Regular maintenance practices can prolong the life of the 201745 Thrust Ring and ensure consistent engine performance. These practices include routine inspections for signs of wear or damage, cleaning the engine to remove debris that could affect the thrust ring’s operation, and following manufacturer recommendations for replacement intervals. Adhering to these maintenance tips helps preserve the engine’s efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of engines and components designed for heavy-duty applications, reflecting a commitment to excellence and customer satisfaction.

Cummins Engine Part 201745: Thrust Ring Compatibility

The Cummins part number 201745, identified as a Thrust Ring, is a critical component in various Cummins engine models. This part is integral to the engine’s operation, providing essential support and stability to the crankshaft and other rotating assemblies. Here is a detailed look at how this thrust ring fits into the specified Cummins engines:

K-Series Engines

- K19

- K38

- K50

The K-Series engines, including the K19, K38, and K50, are designed for heavy-duty applications. The thrust ring part 201745 is compatible with these engines, ensuring the crankshaft remains properly aligned and reducing wear on the engine’s internal components.

L-Series Engines

- L10 MECHANICAL

The L10 MECHANICAL engine is another heavy-duty model where the thrust ring part 201745 is utilized. This part is essential in maintaining the integrity of the engine’s rotating assemblies, contributing to the engine’s overall durability and performance.

M-Series Engines

- M11 CELECT PLUS

- M11 MECHANICAL

Both the M11 CELECT PLUS and M11 MECHANICAL engines benefit from the thrust ring part 201745. This component is crucial in these engines for maintaining the precise alignment of the crankshaft, which is vital for the smooth operation and longevity of the engine.

N-Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine is another robust model that incorporates the thrust ring part 201745. This part plays a significant role in supporting the crankshaft and ensuring that the engine operates efficiently under heavy loads.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine is a high-performance model where the thrust ring part 201745 is essential. This component helps maintain the alignment of the crankshaft, contributing to the engine’s reliability and efficiency.

V-Series Engines

- V28

- V903

The V28 and V903 engines are designed for demanding applications, and the thrust ring part 201745 is a key component in these engines. It ensures that the crankshaft remains properly aligned, which is crucial for the engine’s performance and longevity.

By ensuring the proper fitment of the thrust ring part 201745 in these various Cummins engines, maintenance and reliability are significantly enhanced, providing peace of mind for operators and extending the service life of the engines.

Role of Part 201745 Thrust Ring in Engine Systems

The Part 201745 Thrust Ring is an essential component in the efficient operation of various engine systems. It is primarily responsible for managing axial loads within the engine, ensuring smooth and reliable performance.

In the AFC-VS/TMD system, the thrust ring works in conjunction with the Aftercooler - Variable Speed, Aftercooler Variable Speed Hydraulic Assembly, and Carrier Weight to maintain balance and reduce wear on moving parts. This is particularly important in high-stress environments where precision and durability are paramount.

For the Cummins Electronic Fuel Control Governor and associated components like the FP & Gov. Sump, Fuel D B. H Pump, and Fuel Gear Pump, the thrust ring helps in stabilizing the axial movement of the governor drive cover and non-AFC VS FP/WW sump. This stabilization is vital for the accurate delivery of fuel, directly impacting the engine’s power output and efficiency.

In the Fuel Injection System, which includes the Fuel Injection Pump and Fuel Pump Front Variable Speed Cover, the thrust ring ensures that the high-pressure fuel delivery remains consistent. It supports the Fuel Pump Sub-Option and other related parts, such as the Pump, Fuel, and Pump, Fuel Base, by mitigating axial forces that could otherwise lead to misalignment or failure.

Additionally, the thrust ring plays a significant role in the Variable Speed (VS) system, where it interfaces with the Governor Drive Cover and Uncalibrated VS components. Here, it helps in maintaining the integrity of the fuel delivery process under varying operational speeds, contributing to the overall reliability of the engine.

Overall, the Part 201745 Thrust Ring is a key element in enhancing the performance and longevity of engine systems by effectively managing axial loads and ensuring components operate within their designed parameters.

Conclusion

The Cummins 201745 Thrust Ring is a vital component in heavy-duty truck engines, playing a crucial role in managing axial loads and ensuring the smooth operation of engine systems. Its robust design and precise engineering contribute to the durability, performance, and reliability of the engine. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part. By understanding and utilizing the 201745 Thrust Ring effectively, operators can enhance the efficiency and longevity of their engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.