This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

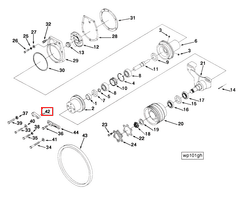

The Cummins 202317 Pillow Block is a specialized bearing unit designed for use in commercial trucks. It serves a significant role in supporting rotating shafts and reducing friction within the truck’s mechanical system. This component is integral to the efficient operation of trucks, contributing to their reliability and performance.

Basic Concepts of Pillow Blocks

A pillow block is a type of bearing unit that houses a bearing and provides a mounting point for a shaft. It typically consists of a housing, a bearing, and a shaft support. The housing is designed to be bolted to a surface, while the bearing allows for smooth rotation of the shaft with minimal friction. Pillow blocks are widely used in various machinery, including conveyors, pumps, and engines, due to their ability to support radial and some axial loads 1.

Purpose of the Cummins 202317 Pillow Block

This Cummins part is engineered to support rotating shafts in commercial trucks. It plays a role in the truck’s mechanical system by providing a stable mounting point for the shaft and incorporating a bearing that reduces friction. This reduction in friction contributes to the overall efficiency and longevity of the truck’s components 2.

Key Features

The Cummins 202317 Pillow Block is characterized by several key features that enhance its performance. These include a robust material composition designed to withstand the rigors of commercial truck operation, a precision-engineered design that ensures optimal shaft alignment, and unique characteristics such as integrated lubrication systems that further reduce friction and wear 3.

Benefits of Using the Cummins 202317 Pillow Block

Incorporating this part into truck designs offers several advantages. Its durable construction contributes to the longevity of the truck’s mechanical system. The design of the pillow block also facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its maintenance benefits include reduced lubrication requirements and straightforward inspection processes 4.

Installation Considerations

When installing the Cummins 202317 Pillow Block, it is important to follow guidelines and best practices to ensure proper function and longevity. Preparatory steps may include cleaning the mounting surface and ensuring that the shaft is properly aligned. The use of appropriate tools and torque settings is also crucial to secure the pillow block in place without overtightening, which could lead to premature wear.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 202317 Pillow Block involves regular inspection for signs of wear or damage, ensuring that the bearing is properly lubricated, and checking for proper shaft alignment. Common issues that may arise include increased friction or noise, which can often be addressed by realigning the shaft or replenishing lubrication. In more severe cases, the bearing may need to be replaced.

Performance in Various Conditions

The Cummins 202317 Pillow Block is designed to perform under a range of operating conditions. It is capable of withstanding varying temperatures, loads, and environments that are typical in commercial truck operations. Its robust construction and precision engineering allow it to maintain performance and reliability in these diverse conditions.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance and efficiency of commercial vehicles.

Role of Part 202317 Pillow Block in Engine Systems

The Part 202317 Pillow Block is an essential component in the efficient operation of various engine systems. Its primary function is to provide a stable mounting point for rotating components, ensuring smooth operation and reducing friction.

Integration with Fan Arrangement

In the fan arrangement of an engine, the Pillow Block serves as a pivotal support structure. It securely houses the fan shaft, allowing it to rotate with minimal resistance. This setup ensures that the fan operates efficiently, providing adequate airflow to cool the engine components. The stable mounting offered by the Pillow Block helps in maintaining the alignment of the fan shaft, which is vital for the consistent performance of the cooling system.

Contribution to Water Pump Functionality

When integrated with the water pump, the Pillow Block plays a significant role in the circulation of coolant within the engine. It supports the impeller shaft of the water pump, enabling it to rotate smoothly and effectively. This rotation is essential for the proper circulation of coolant, which helps in maintaining optimal engine temperature. The Pillow Block’s design ensures that the impeller shaft remains aligned and operates with reduced wear and tear, contributing to the longevity and reliability of the water pump.

Conclusion

The Cummins 202317 Pillow Block is a critical component in the mechanical systems of commercial trucks, offering durability, ease of installation, and maintenance benefits. Its role in supporting rotating shafts and reducing friction contributes significantly to the efficiency and reliability of truck operations. Proper installation and maintenance are essential to ensure the longevity and performance of this part in various operating conditions.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.