This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

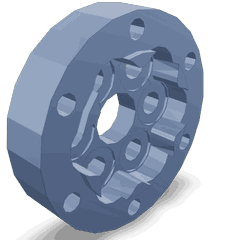

The Cummins 212112 Power Takeoff (PTO) Flange is a component designed to facilitate the transfer of power from a truck’s engine to auxiliary equipment. This part is integral to the operation of commercial trucks, enabling them to perform a wide range of tasks beyond simple transportation. Understanding its function and significance can enhance the efficiency and versatility of commercial vehicle operations.

Basic Concepts of Power Takeoff Flanges

A Power Takeoff (PTO) Flange is a mechanical device that allows power from the engine to be transferred to auxiliary equipment. This transfer is achieved through a series of gears and shafts that connect the engine to the equipment. The PTO Flange, specifically, serves as the connection point between the PTO unit and the auxiliary equipment, ensuring a secure and efficient transmission of power 1.

Purpose of the 212112 Power Takeoff Flange

The 212112 Power Takeoff Flange plays a specific role in the operation of a truck by providing a reliable connection for auxiliary equipment. This flange is utilized in various types of commercial vehicles, including construction trucks, agricultural machinery, and other heavy-duty vehicles. Its purpose is to ensure that the power transmitted from the engine is effectively utilized by the attached equipment, enhancing the truck’s functionality and operational capabilities.

Key Features

The 212112 Power Takeoff Flange is characterized by several key features that enhance its performance and durability. These include a robust design that ensures a secure connection, the use of high-quality materials to withstand the rigors of heavy-duty use, and unique attributes such as precision machining for optimal fit and function. These features contribute to the flange’s reliability and efficiency in commercial truck applications.

Benefits

The benefits provided by the 212112 Power Takeoff Flange include improved efficiency in power transmission, enhanced reliability due to its durable construction, and ease of use, which simplifies the process of connecting and disconnecting auxiliary equipment. These advantages make it a valuable component in the operation of commercial trucks, contributing to overall operational effectiveness 2.

Installation Process

The installation process of the 212112 Power Takeoff Flange involves several steps to ensure a proper and secure fit. Prerequisites include ensuring the truck’s PTO system is compatible with the flange and gathering the necessary tools. The installation steps typically involve aligning the flange with the PTO unit, securing it in place, and verifying the connection’s integrity. Detailed instructions should be followed to ensure a successful installation.

Common Applications

The 212112 Power Takeoff Flange is commonly used in a variety of applications, including construction equipment such as cranes and excavators, agricultural machinery like plows and harvesters, and other heavy-duty vehicles that require the transfer of engine power to auxiliary equipment. Its versatility makes it a crucial component in many commercial vehicle operations.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the 212112 Power Takeoff Flange, regular maintenance and troubleshooting are necessary. Common issues may include misalignment, wear, or damage to the flange. Guidelines for troubleshooting involve inspecting the flange for signs of wear, ensuring proper alignment, and making adjustments as needed. Maintenance tips include regular cleaning, lubrication, and periodic inspection to prevent issues and ensure safe operation.

Safety Considerations

When installing, using, and maintaining the 212112 Power Takeoff Flange, several safety considerations are important to prevent accidents and ensure safe operation. These include wearing appropriate personal protective equipment, ensuring the truck is turned off and the PTO system is disengaged before installation or maintenance, and following all manufacturer guidelines and safety protocols. Adhering to these safety considerations is crucial for the safe and effective use of the flange.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding needs of commercial vehicle operators.

Power Takeoff Flange (Part 212112) Compatibility with Cummins Engines

The Power Takeoff Flange, identified by part number 212112, is a critical component designed to interface with various Cummins engines. This flange is engineered to facilitate the transfer of power from the engine to auxiliary equipment, ensuring seamless operation and reliability.

G855 Series Engines

The G855 series, which includes the G855 CM558 and GTA855 CM558 (CM2358) G101, are robust engines known for their durability and efficiency. The Power Takeoff Flange 212112 is specifically designed to fit these engines, providing a secure connection point for power transfer applications.

N14 Series Engines

The N14 series engines, comprising the N14 CELECT, N14 CELECT PLUS, N14 G, and N14 MECHANICAL, are widely used in various industries due to their versatility and performance. The flange 212112 is compatible with these engines, ensuring a reliable connection for power takeoff operations.

NH/NT 855 Engines

The NH/NT 855 engines are another set of Cummins engines that benefit from the Power Takeoff Flange 212112. This flange is engineered to fit these engines, providing a secure and efficient means of transferring power to auxiliary equipment.

QSNT14 CM876 N102

The QSNT14 CM876 N102 engine is designed for high-performance applications. The Power Takeoff Flange 212112 is compatible with this engine, ensuring that power transfer is both reliable and efficient.

Each of these engines, despite their differences, is designed to work seamlessly with the Power Takeoff Flange 212112, ensuring that power transfer operations are conducted smoothly and effectively.

Role of Part 212112 Power Takeoff Flange in Engine Systems

The Part 212112 Power Takeoff Flange is an integral component in the efficient operation of various engine systems. It interfaces with several key components to ensure smooth power transmission and reduction of mechanical stress.

Interaction with Dampers and Vibration Control Components

The Power Takeoff Flange works in conjunction with dampers such as the EBM: Damper and the Front Power Take-Off Damper Pulley. These dampers are designed to absorb vibrations generated by the engine, ensuring that the power transmission through the flange is smooth and free from excessive oscillations. The Vibration Damper further aids in this process by reducing the vibrational energy that could otherwise be transmitted to the Power Takeoff Flange, thereby enhancing the durability and reliability of the entire system.

Connection to Pulleys and Adapters

The flange is also designed to connect with pulleys like the EBM: Pulley and the Front Power Take-Off Pulley. These pulleys are essential for driving various auxiliary components such as generators, compressors, and hydraulic pumps. The Power Takeoff Flange ensures a secure and efficient transfer of rotational force from the crankshaft to these pulleys, facilitating the operation of the connected systems.

Integration with Crankshaft and Front Drive Systems

A significant role of the Part 212112 Power Takeoff Flange is its integration with the Crankshaft and the Front Drive system. The flange is bolted or keyed to the crankshaft, allowing it to transmit the engine’s rotational energy to the front power take-off components. The EBM: Adapter and the Front Drive components rely on this flange to maintain a consistent and reliable connection, ensuring that the front-mounted accessories receive the necessary power without interruption.

Enhanced Performance with EBM Components

When paired with EBM components such as the EBM: Adptr Front Drive and the EBM: Adapter, the Power Takeoff Flange enhances the overall performance of the engine system. These adapters and front drive components are precision-engineered to work seamlessly with the flange, providing a robust and efficient power transmission pathway. This integration minimizes power loss and maximizes the efficiency of the engine’s auxiliary systems.

Conclusion

In summary, the Part 212112 Power Takeoff Flange plays a vital role in connecting and facilitating the smooth operation of various engine components, ensuring efficient power transmission and reduced mechanical stress. Its compatibility with a range of Cummins engines and its integration with key engine components make it an essential part of commercial vehicle operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.