Introduction

The Cummins 213235 Crankshaft Pulley is a vital component in commercial trucks equipped with Cummins engines. It facilitates the transfer of rotational force from the crankshaft to auxiliary components, ensuring the engine’s efficiency and reliability. Understanding its function and significance is essential for maintaining commercial trucks.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, or harmonic balancer, connects the crankshaft to the serpentine or timing belt system. It drives accessories like the alternator, power steering pump, and air conditioning compressor by converting the linear motion of the pistons into rotational motion. The relationship between the crankshaft pulley and other engine components is crucial for synchronized engine operation 1.

Purpose of the Cummins 213235 Crankshaft Pulley

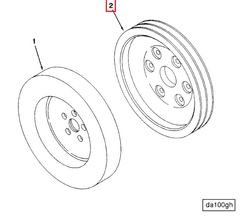

This Cummins part ensures the efficient running of the engine by maintaining the proper alignment and tension of the serpentine belt. This allows for the seamless transmission of power to essential engine accessories. The pulley’s design reduces vibrations and ensures smooth engine operation, which is vital for the truck’s performance and longevity 2.

Key Features

The Cummins 213235 Crankshaft Pulley is characterized by its robust design and high-quality materials. It features a durable construction that enhances its performance and longevity. The pulley is engineered to withstand the high stresses and vibrations associated with heavy-duty truck engines. Its design includes precision-machined surfaces to ensure a perfect fit and optimal performance.

Benefits

This part offers several advantages, including improved engine performance, enhanced durability, and increased reliability. These benefits contribute to the overall efficiency and longevity of the truck. By ensuring the proper operation of engine accessories, the pulley plays a role in maintaining the truck’s performance and reducing the likelihood of engine-related issues.

Installation and Compatibility

Proper installation of the Cummins 213235 Crankshaft Pulley is crucial for its effective operation. The installation process may require specific tools and equipment to ensure a secure fit. The pulley is compatible with a range of Cummins engines and truck models, making it a versatile component for various applications.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 213235 Crankshaft Pulley is important to ensure its optimal performance. This includes checking for signs of wear or damage and ensuring the serpentine belt is properly tensioned. Common issues may include belt slippage or pulley misalignment, which can be addressed through routine inspections and adjustments.

Performance Enhancements

The Cummins 213235 Crankshaft Pulley can contribute to performance enhancements in commercial trucks. Modifications or upgrades, such as using a higher-quality serpentine belt or ensuring proper pulley alignment, can further improve its functionality and the overall performance of the truck.

Safety Considerations

When working with the Cummins 213235 Crankshaft Pulley, it is important to adhere to safety protocols. This includes ensuring the engine is off and cooled down before beginning any work. Potential hazards may include moving parts or high-temperature components, so appropriate safety measures should be taken to prevent accidents.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s focus on customer satisfaction and technological advancement underscores its position as a leader in the field.

Understanding the Integration of Part 213235 Crankshaft Pulley in Engine Systems

The part 213235 Crankshaft Pulley is an essential component in the synchronization and efficient operation of various engine systems. Its primary function is to transmit rotational force from the crankshaft to other engine components, ensuring smooth and consistent power delivery.

Interaction with the Damper

The crankshaft pulley, specifically part 213235, works in conjunction with the damper to mitigate the torsional vibrations generated by the engine’s operation. The damper, often integrated within the pulley assembly, absorbs these vibrations, preventing them from being transmitted to other engine components. This interaction ensures that the crankshaft’s rotation is smooth, reducing wear and tear on the engine’s internal components and contributing to the overall longevity of the engine 1.

Role in the Pulley System

In the pulley system, the crankshaft pulley serves as the primary driver. It is responsible for transferring the crankshaft’s rotational energy to the serpentine belt, which in turn drives accessories such as the alternator, power steering pump, and air conditioning compressor. The efficient transfer of this energy is vital for the proper functioning of these accessories, ensuring that they operate at optimal levels without placing undue stress on the engine 2.

Vibration Damping Functionality

The vibration damper, often a part of the pulley assembly, plays a significant role in maintaining engine stability. By dampening the torsional vibrations, it helps in maintaining a consistent rotational speed of the crankshaft. This consistency is essential for the precise timing of engine operations, such as fuel injection and valve timing, which are critical for engine performance and efficiency.

Comprehensive Engine System Integration

The integration of part 213235 Crankshaft Pulley within the engine system is a testament to the intricate balance required for optimal engine performance. Its role in driving the pulley system, working in tandem with the vibration damper, and ensuring the smooth operation of engine accessories underscores its importance in the engine’s overall functionality.

Understanding these interactions provides a deeper appreciation for the complexities of engine design and the importance of each component in achieving efficient and reliable engine operation.

Conclusion

The Cummins 213235 Crankshaft Pulley is a critical component in the operation of commercial truck engines. Its robust design, precise engineering, and compatibility with various Cummins engines make it a reliable choice for maintaining engine performance and longevity. Proper installation, regular maintenance, and adherence to safety protocols are essential for ensuring the optimal operation of this part. Understanding its role in the engine system highlights the importance of each component in achieving efficient and reliable engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.