This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

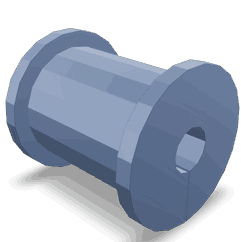

The 2830268 Vibration Isolator, manufactured by Cummins, is a vital component in the commercial truck industry. This part is designed to mitigate engine and drivetrain vibrations, ensuring the integrity and performance of truck systems.

Basic Concepts of Vibration Isolators

Vibration isolators are devices that reduce the transmission of vibrations from a source to a structure. They absorb or deflect vibrational energy, minimizing its impact on connected components. This principle helps maintain equipment integrity and performance by preventing excessive vibrations that can lead to wear, fatigue, and potential failure of parts 1.

Purpose of the 2830268 Vibration Isolator

The 2830268 Vibration Isolator is designed to reduce vibrations transmitted from the engine or drivetrain to the truck’s frame and cabin. This results in a smoother operation, improved ride comfort, and reduced stress on various truck components 2.

Key Features

This Cummins part features a robust design with high-quality materials and advanced technological aspects to enhance performance. Its material composition is chosen for durability and effectiveness in vibration absorption. Design elements such as shape and mounting points are optimized for efficient vibration isolation. Unique technological aspects incorporated into this isolator contribute to its overall performance and reliability 3.

Benefits

Using the 2830268 Vibration Isolator offers several advantages. It improves ride comfort by reducing vibrations felt by the driver and passengers. It also reduces wear and tear on truck components, leading to longer component lifespan and lower maintenance costs. Enhanced comfort contributes to a better driving experience and safety.

Installation and Integration

Proper installation of the 2830268 Vibration Isolator is crucial for optimal performance. Guidelines for installation include checking for any prerequisites or considerations that may affect its functionality. This part is designed to integrate seamlessly with other truck components, ensuring effective operation within the truck’s system.

Troubleshooting and Maintenance

Identifying common issues with vibration isolators and performing regular maintenance can help ensure the longevity and effective performance of the 2830268 Vibration Isolator. Diagnostic procedures may involve checking for signs of wear or damage, and maintenance practices could include regular inspections and replacements as needed.

Performance and Efficiency

The 2830268 Vibration Isolator contributes to the overall performance and efficiency of the truck. By reducing vibrations, it can help maintain fuel efficiency and engine performance. Other relevant metrics may also be positively affected by the use of this vibration isolator, contributing to the truck’s operational effectiveness.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer in the commercial truck industry, known for its high-quality products and innovative solutions. With a rich history and a strong reputation, Cummins offers a range of products designed to meet the demands of commercial truck operations. The 2830268 Vibration Isolator is one example of Cummins’ commitment to providing reliable and effective components for the trucking industry.

Role of Part 2830268 Vibration Isolator in Engine Systems

The 2830268 Vibration Isolator is instrumental in maintaining the integrity and performance of various engine components by mitigating vibrations that can adversely affect their operation.

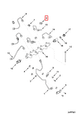

Integration with Fuel Supply Components

When integrated with the Fuel Supply Tube and Injector Fuel Supply Tube, the Vibration Isolator helps stabilize the fuel delivery system. This stabilization ensures consistent fuel flow, which is essential for optimal engine performance. By reducing vibrations, it prevents potential leaks and wear on the fuel supply components, thereby enhancing the reliability of the fuel system.

Enhancing Injector Performance

In conjunction with the Injector and Injector Plumbing, the Vibration Isolator plays a significant role in maintaining precise fuel injection. Vibrations can cause misalignment or wear in the injector components, leading to inefficient fuel delivery. The isolator absorbs these vibrations, ensuring that the injector operates smoothly and delivers fuel with the required precision, which is vital for engine efficiency and performance.

Overall System Stability

The Vibration Isolator also contributes to the stability of the Plumbing system within the engine. By dampening vibrations, it protects the plumbing from stress and fatigue, which can lead to cracks or failures over time. This protection is essential for maintaining the overall integrity of the engine’s fluid systems, ensuring they function reliably under various operating conditions.

Conclusion

The 2830268 Vibration Isolator is a key component in enhancing the performance and longevity of engine systems by effectively managing vibrations across critical components. Its integration with fuel supply components, injectors, and plumbing systems ensures consistent fuel flow, precise fuel injection, and overall system stability, contributing to improved engine efficiency and reliability.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

The Diesel Engine Second Edition, Michael Hilgers, Springer Nature, 2023.

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.