This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

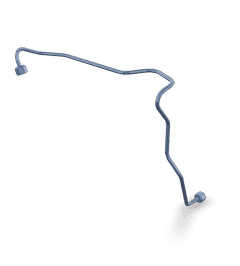

The Injector Fuel Supply Tube 2831153, designed by Cummins, is a critical component in the fuel system of commercial trucks. This part facilitates the delivery of fuel from the fuel tank to the injectors, ensuring efficient and reliable engine operation.

Basic Concepts

Injector fuel supply tubes are essential for transporting fuel under pressure from the fuel pump to the injectors in diesel engines. The efficiency of this process directly impacts engine performance, including power output, fuel economy, and emissions 1.

Purpose and Function

This Cummins part plays a role in the operation of a truck by delivering fuel to the injectors under precise pressure and timing. This ensures correct fuel atomization upon injection into the combustion chamber, which is important for efficient combustion. It also maintains the integrity of the fuel system by providing a secure and leak-free pathway for fuel, especially in high-pressure common rail systems 2.

Key Features

The Injector Fuel Supply Tube 2831153 is constructed from materials that offer durability and resistance to diesel fuel’s corrosive effects. Its design includes precise machining for tight tolerances, ensuring a secure fit within the fuel system. Additionally, the tube may incorporate elements that reduce the risk of fuel leaks and improve the overall reliability of the fuel delivery system.

Benefits

Utilizing this part in a truck’s fuel system can lead to improved fuel delivery efficiency, contributing to better engine performance, increased power and torque, and improved fuel economy. Furthermore, the tube’s design and construction contribute to increased reliability, even under demanding operating conditions 3.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube 2831153 is crucial for ensuring its effective operation and the overall efficiency of the fuel system. Installation procedures should follow manufacturer guidelines to ensure compatibility with Cummins engines and fuel systems. This includes verifying that all connections are secure and that the tube is correctly positioned within the fuel system to prevent leaks and ensure optimal fuel delivery.

Maintenance and Troubleshooting

Regular maintenance of the Injector Fuel Supply Tube 2831153 is important for sustaining its performance and longevity. This includes periodic inspections for signs of wear, corrosion, or leaks. Troubleshooting common issues may involve checking for proper fuel pressure, ensuring secure connections, and verifying the integrity of the tube itself. Adhering to recommended maintenance intervals and procedures can help prevent unexpected failures and ensure consistent engine performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. Their product offerings include a wide range of engines and components designed to meet the demanding requirements of commercial applications, ensuring reliability, performance, and efficiency.

Compatibility

The Injector Fuel Supply Tube (2831153) is specifically designed to fit the B6.7S engine series. This part is integral to the engine’s fuel system, ensuring that the injectors receive the correct amount of fuel under the right pressure, which is crucial for the engine’s combustion process.

Importance of the Fuel Supply Tube

The fuel supply tube plays a role in the engine’s operation by:

- Ensuring a consistent and reliable fuel supply to the injectors.

- Maintaining the integrity of the fuel delivery system by preventing leaks.

- Contributing to the overall efficiency and performance of the engine by facilitating precise fuel metering.

Installation and Maintenance

Proper installation and regular maintenance of the injector fuel supply tube are essential to avoid potential issues such as fuel leaks, engine misfires, or reduced performance. It is recommended to use genuine Cummins parts for replacement to ensure compatibility and reliability.

Role in Engine Systems

The Injector Fuel Supply Tube, specifically part 2831153, is an integral component in the fuel delivery system of an engine. It is responsible for transporting pressurized fuel from the fuel rail to the individual fuel injectors. This ensures that each injector receives a consistent and regulated fuel supply, which is essential for precise fuel metering and efficient combustion.

In conjunction with the injector plumbing, the Injector Fuel Supply Tube forms a network that facilitates the seamless flow of fuel. The injector plumbing includes various components such as fuel lines, connectors, and fittings that work together to maintain the integrity of the fuel system. The Injector Fuel Supply Tube plays a significant role in this network by providing a direct and unobstructed path for fuel to travel from the fuel rail to the injectors.

The fuel rail, a pressurized manifold, distributes fuel to each injector via the Injector Fuel Supply Tube. This setup allows for uniform fuel pressure across all injectors, which is vital for balanced engine performance and emissions control. The consistent fuel pressure ensures that each cylinder receives the correct amount of fuel, leading to optimal combustion efficiency and power output.

Furthermore, the Injector Fuel Supply Tube is designed to withstand the high pressures and temperatures within the fuel system. Its robust construction and precise engineering ensure reliable performance under various operating conditions. This reliability is essential for maintaining the overall efficiency and durability of the engine.

Conclusion

In summary, the Injector Fuel Supply Tube 2831153 is a key component in the fuel delivery system, working in tandem with the injector plumbing and fuel rail to ensure consistent and efficient fuel distribution to the injectors. This contributes to the engine’s performance, fuel economy, and emissions efficiency.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.