This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2862355 Catalyst Module is a component designed for use in the emissions control systems of commercial trucks. Its purpose is to reduce harmful emissions produced by diesel engines, ensuring compliance with environmental regulations and contributing to cleaner air quality. This module is integral to the overall emissions control strategy employed in modern commercial vehicles.

Basic Concepts of Catalyst Modules

A catalyst module is a device that facilitates chemical reactions to convert harmful exhaust gases into less harmful substances. Within an emissions control system, it operates by utilizing a catalyst—typically a precious metal such as platinum, palladium, or rhodium—to accelerate the conversion of pollutants. The basic principle of catalytic conversion involves the oxidation of carbon monoxide (CO) and hydrocarbons (HC) into carbon dioxide (CO2) and water (H2O), and the reduction of nitrogen oxides (NOx) into nitrogen (N2) and oxygen (O2) 1.

Purpose and Function of the 2862355 Catalyst Module

The Cummins 2862355 Catalyst Module plays a specific role in the operation of a truck’s exhaust system. Positioned downstream of the engine, it interacts with exhaust gases after they have passed through the turbocharger and other preliminary emissions control devices. The module works in conjunction with other components, such as diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems, to ensure comprehensive emissions control 2.

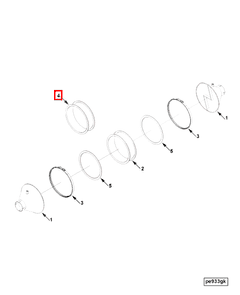

Key Features

The 2862355 Catalyst Module is characterized by several key features that enhance its performance. Its design incorporates a robust housing that protects the internal catalyst materials from physical damage. The module utilizes high-quality catalyst materials to ensure efficient conversion of exhaust gases. Additionally, it may include technological aspects such as advanced substrate materials that maximize surface area for catalytic reactions, contributing to its effectiveness 3.

Benefits of Using the 2862355 Catalyst Module

The advantages of employing the 2862355 Catalyst Module include significant improvements in emissions reduction. By effectively converting harmful exhaust gases, the module helps trucks meet stringent environmental regulations. Furthermore, its efficient design may contribute to increased engine efficiency, as optimized emissions control can lead to better overall engine performance 4.

Installation and Integration

Proper installation of the 2862355 Catalyst Module is vital for its effective operation. It is designed to be compatible with various truck models, ensuring a seamless integration within the exhaust system. The installation process involves careful positioning and secure mounting to prevent leaks and ensure stable operation. Integration with other emissions control components is straightforward, allowing for a cohesive emissions management system.

Maintenance and Care

Routine maintenance of the 2862355 Catalyst Module is necessary to ensure its optimal performance. This includes regular inspection for physical damage, monitoring catalyst efficiency, and cleaning as required to remove any accumulated contaminants. Replacement guidelines should be followed to maintain the module’s effectiveness over time.

Troubleshooting Common Issues

Frequent problems associated with the 2862355 Catalyst Module may include reduced efficiency due to catalyst poisoning or physical damage. Diagnostic techniques involve assessing catalyst performance through emissions testing and visual inspection for damage. Solutions may range from cleaning the module to replacing damaged components, ensuring continued effective operation.

Environmental Impact

The Cummins 2862355 Catalyst Module contributes to reducing the environmental footprint of commercial trucks by effectively controlling emissions. Through the conversion of harmful exhaust gases into less harmful substances, it plays a role in mitigating air pollution and promoting cleaner air quality.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation in diesel engine technology and emissions solutions, Cummins is committed to providing reliable, efficient, and environmentally responsible power systems for various applications, including commercial trucks.

Compatibility with Cummins Engines

The 2862355 Catalyst Module, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and compliance with emission standards. This part is integral to the exhaust system of these engines, playing a crucial role in reducing harmful emissions.

G5.9 CM558 and G8.3 CM558

The G5.9 CM558 and G8.3 CM558 engines are part of Cummins’ lineup that benefit significantly from the integration of the Catalyst Module 2862355. These engines, known for their robust performance and reliability, are commonly used in various industrial and commercial applications. The Catalyst Module is engineered to fit precisely with these engines, ensuring that the exhaust gases are treated effectively before being released into the environment.

G855 CM558

Similarly, the G855 CM558 engine is another variant that is compatible with the Catalyst Module 2862355. This engine is designed for heavy-duty applications, and the Catalyst Module plays a vital role in maintaining its efficiency and reducing its environmental impact. The fitment of this part is critical to the overall performance and longevity of the engine.

Installation and Integration

The installation of the Catalyst Module 2862355 in these engines is a straightforward process, designed to be integrated into the existing exhaust system without requiring significant modifications. This ensures that the engines continue to operate at peak efficiency while adhering to stringent emission regulations. The design of the Catalyst Module allows for easy replacement and maintenance, making it a practical choice for operators who need to ensure their engines remain compliant with environmental standards.

Performance and Reliability

The Catalyst Module 2862355 is engineered to withstand the demanding conditions of industrial and commercial engines. Its robust construction and high-quality materials ensure that it can endure the high temperatures and pressures associated with engine operation. This reliability is crucial for maintaining the performance of the G5.9 CM558, G8.3 CM558, and G855 CM558 engines over their operational lifespan.

Role in Aftertreatment Systems

The 2862355 Catalyst Module is an integral component within the aftertreatment system of an engine. Its primary function is to facilitate the conversion of harmful exhaust emissions into less harmful substances before they are released into the atmosphere.

When exhaust gases exit the engine, they pass through the exhaust manifold and enter the turbocharger, if present. Post-turbocharging, the gases travel through the exhaust pipe and reach the 2862355 Catalyst Module. Here, the module interacts with other aftertreatment devices such as Diesel Oxidation Catalysts (DOC), Diesel Particulate Filters (DPF), and Selective Catalytic Reduction (SCR) systems.

In coordination with the DOC, the 2862355 Catalyst Module helps oxidize carbon monoxide (CO) and hydrocarbons (HC) into carbon dioxide (CO2) and water (H2O). When integrated with the DPF, it aids in the reduction of particulate matter by ensuring that the filter operates efficiently and regenerates when necessary.

Furthermore, in systems equipped with SCR, the 2862355 Catalyst Module works in tandem to reduce nitrogen oxides (NOx) by promoting the chemical reactions necessary for their conversion into nitrogen (N2) and water vapor.

The module is also connected to various sensors and control units that monitor its performance and adjust the aftertreatment processes in real-time to maintain optimal efficiency and compliance with emission standards.

Overall, the 2862355 Catalyst Module plays a significant role in enhancing the effectiveness of the aftertreatment system, ensuring that the engine operates cleanly and meets environmental regulations.

Conclusion

The Cummins 2862355 Catalyst Module is a critical component in the emissions control systems of commercial trucks. Its role in converting harmful exhaust gases into less harmful substances ensures compliance with environmental regulations and contributes to cleaner air quality. The module’s compatibility with various Cummins engines, ease of installation, and robust performance make it an essential part of modern emissions control strategies.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics, Creative Commons, 2024.

↩ -

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩ -

Reza N. Jazar, Vehicle Dynamics: Theory and Application, Springer, 2017.

↩ -

Tom Denton and Hayley Pells, Automotive Technician Training, Second Edition, Routledge, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.